Participation in PCIM Europe Underscores Growing Importance of Power Electronics

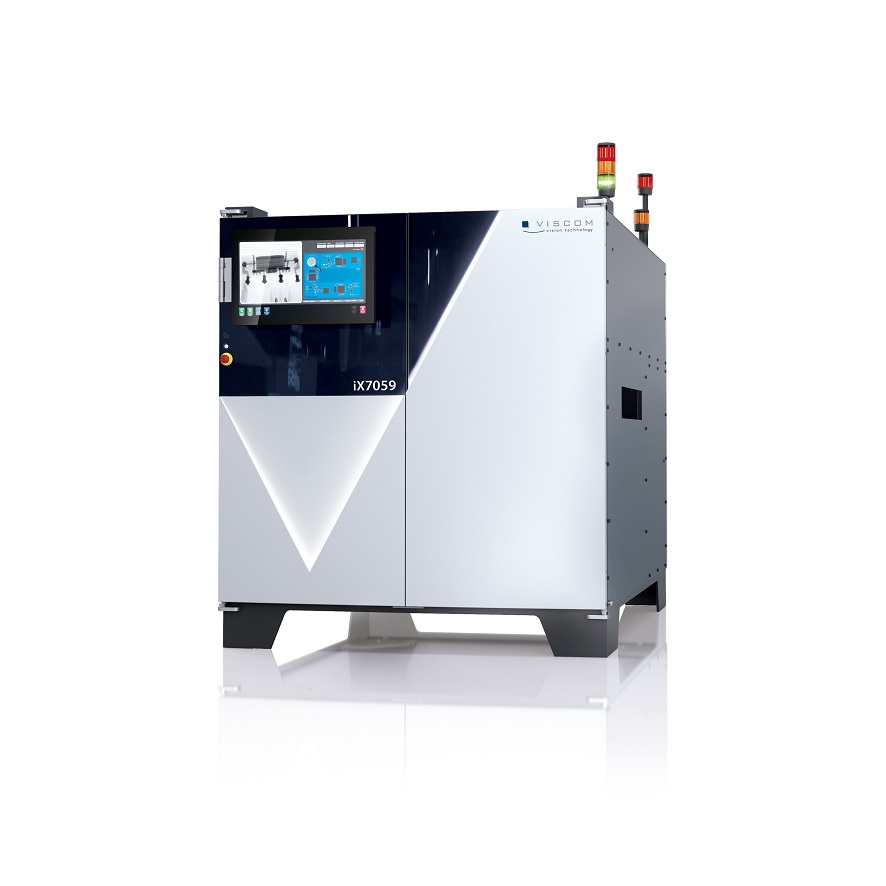

Hanover, Germany, April 26, 2022 – Viscom AG is exhibiting at the PCIM Europe trade fair for the first time this year. The team of experts at Stand 6-110 will provide detailed information about inspection solutions from Viscom for the special requirements of power electronics. A particular highlight set to be shown live is the iX7059 Module Inspection inline X-ray system. Another focus is on high-precision optical wire bond inspection.

As an exhibition for power electronics, PCIM Europe focuses on hot trends in renewable energies, intelligent drive technologies and energy management. It will be held from May 10 to 12 in Nuremberg, Germany, parallel to the electronics trade fair SMTconnect right next door. Exhibiting at both events, Viscom will exclusively present its new iX7059 Module Inspection inline X-ray inspection system at PCIM Europe. This system was developed specially as a customized solution for increasing demands on the quality inspection of power semiconductors.

The 3D AXI system iX7059 Module Inspection from Viscom irradiates surface soldering all-around perfectly – even if the inspection objects have special heat sinks. Often made of copper, these might also constitute interference structures that make inspection difficult. In such cases, stronger radiation is required. Using high-performance computed tomography, the iX7059 Module Inspection generates precise volume views and layer images that provide accurate information about the void content in the connections, amongst other parameters. To inspect typical test objects such as IGBT modules in a cycle-time optimized manner, handling options with special frames and workpiece carriers are also part of the system concept.

At PCIM Europe, Viscom will also be addressing the latest 2D and 3D approaches to wire bond inspection – specially adapted to requirements of power electronics. Typical applications (e.g. inverter technology) can be found in power supply with regenerative energy sources, railroad control systems and especially in electromobility with its hybrid or purely battery-powered electric vehicles. The solutions presented are intended for one hundred percent inline testing through to the measurement of wire runs. At an offline programming station at the Viscom PCIM Stand, visitors can see how individual steps are created and implemented for precise inspection.

Anyone wishing to learn even more about the topic of 3D bonding can have the S6053BO-V inspection system demonstrated at Viscom's Stand 4A-120 at SMTconnect – where they can also discover many other state-of-the-art inspection gates from Viscom and their extensive networking.