Thermaltronics Embraces Strict Quality Control for Superior Solder Robots

GREAT NECK, NY — June 2022 — Thermaltronics USA, Inc. is pleased to announce that its solder robots go through extensive quality control procedures in order to maintain the company’s position as the most awarded, accurate and versatile solder robot on the market.

Thermaltronics embraces both strict quality control and conformance with International Manufacturing Standards, is in compliance with ISO 9000 & ISO 14000 and holds certification in TuV, GS, NRTL & CE.

Thermaltronics manufactures and supplies a wide range of soldering products and accessories used in the electronics manufacturing industry. Design and development is undertaken in the USA and Australia, with final production taking place in a customized manufacturing facility, incorporating specialized equipment and in accordance with recognized international standards of quality and compliance.

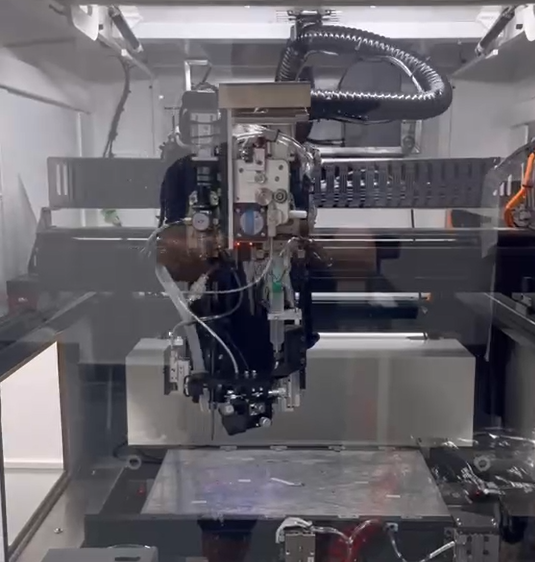

The Thermaltronics Robot System incorporates innovative design concepts and precision components to ensure accuracy. The combination of high precision hardware and intelligent software ensures precision soldering and low operator training costs.

Unlike typical Cartesian robots the Thermaltronics Robot, Model TMT-R9900S, is equipped with full vision to verify the procedure being undertaken and does not simply follow a pre-determined program. In this respect it has an observation mode, a verification mode and as a result – a decision making capability. This capability of collecting and utilizing data for production processing is one of the most important factors necessary to meet the requirements of Industry 4.0 standards.

In addition to its award-winning hand soldering product line, Thermaltronics also provides an extended range of accessories to support both production and rework applications. Customers who wish to run free of charge trials on Thermaltronics hand soldering products are encouraged to contact info@thermaltronics.com. For more information, visit www.thermaltronics.com.