Transitioning from SnPb to Pb-Free Solder

Precautions should be taken to prevent cross-contamination of disparate materials.

As part of a changeover from SnPb assembly to Pb-free, an electronics manufacturer chose SnAg0.3Cu0.7 (SACX) alloy as a replacement. Almost immediately came the headaches – problems that included pad lifting and poor through-hole penetration. The boards were coated with SnCuNi surface finish and had a thickness of 0.062˝. The components were through-hole with SnPb surface finish and pin-to-hole (aspect) ratios of 0.48 to 0.54.

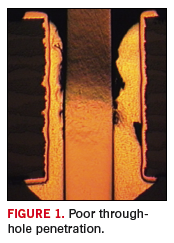

Three components per board were chosen to be cross-sectioned. The cross-sections were inspected using a microscope and a scanning electron microscope (SEM). Figure 1 shows poor through-hole penetration of one of the components. Lack of wetting was observed on the component lead, resulting in lack of soldering inside the barrel. This problem was observed with several components subsequently examined.

Due to lack of virgin material for testing, it was suggested the root cause of this problem might possibly be poor plating of the component leads, which did not help the solder to wick up and fill the barrel. It was also considered possible that the flux was burning off during preheating and was therefore not active during soldering. Without flux during soldering, oxidation is produced, which impedes wetting.

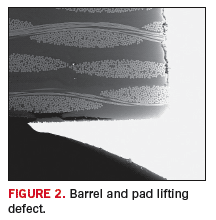

The second problem was pad lifting. SEM analysis of solder joints showed several instances not only of pad lifting, but also barrel lifting (Figure 2). During soldering, the board when heated expands in the Z-direction, and contracts during cooling. Therefore, pad and barrel lifting is an effect and not a defect in which the solder pad/barrel lifts from the board as it cools. The joint formation stress is incremented by the mismatch of the coefficient of thermal expansion of the materials used. In this case, the presence of lead on the component leads migrates to the joint and forms a secondary alloy that has a lower melting point, resulting in a CTE mismatch with the Pb-free alloy. Nevertheless, none of these problems is considered a defect. IPC-A-610D states pad lifting is considered a defect for Classes 1, 2 and 3 when the separation between land and laminate surface is greater than one pad thickness, and IPC-A-600G states resin recession is acceptable for all classes after thermal stress, unless specified by customer.

The copper barrel consists of a thin electroless copper deposited to the drilled laminate, and a codeposit of electrolytic copper plating. The strength of the copper barrel adhesion is determined by the quality of the drilled hole and electroless copper deposit, and the thickness of the electrolytic copper, which should be at least 0.001˝.

Pb-free alloys interact with other materials in occasionally negative ways. Precautions should be taken to prevent cross-contamination of Pb-bearing and Pb-free materials, well outside of the RoHS compliance issue, because in fact, it might become a manufacturing and product reliability issue.

It is also important to optimize the wave profile every time there is change in materials. General recommendations for the improvement of through-hole penetration include: Increase the solder temperature; use a stronger flux, or use a “smart” wave. To reduce pad lifting, avoid low-melting solder contamination, optimize material selection, or keep solder temperature at its lowest practical set point. If possible, higher Tg and lower CTE laminates should be used.

Ursula Marquez de Tino, Ph.D. is a process and research engineer at Vitronics-Soltec, based in the Unovis SMT Lab (vitronics-soltec.com); umarquez@vsww.com. Her column appears monthly.