The Big Mack Attack

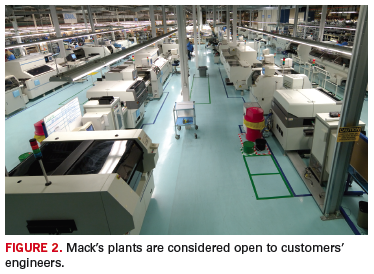

Mid-tier EMS provider Mack Technologies uses a data-driven approach to satisfy customers.

For two years running, Mack Technologies has taken home top honors in Circuits Assembly’s Service Excellence Awards for companies of $100 million to $500 million in annual revenues. What’s its secret?

A customer service strategy based on execution performance and using data, derived through open and honest communication with customers, to drive improvements in performance, company officials say. Westford, MA-based Mack (macktech.com) attributes its ability to follow this strategy to an evolving corporate culture that places a high value on supporting customer requests and exceeding expectations.

In an interview with Circuits Assembly, president John Kovach and vice president of sales and marketing Will Kendall described Mack as a fairly conservative company, one that chooses its customers as much as it is chosen by them. Mack, they said, pays close attention to its customers’ financial stability and engineering needs, and once engaged, spends countless hours assessing their customers’ needs and Mack’s performance in meeting those needs. Excerpts:

CA: Describe Mack’s quality system.

JK: Employee performance is evaluated based in part on customer quality scorecards. We do the same things the same ways in all three sites. Profit sharing is tied to company profitability and customer satisfaction. The scorecard looks at five to six aspects with detailed subheadings. We ask for comments and feedback for any score that’s not best in class. Program managers and executive sponsor (VP, GM, president) for most accounts.

We meet as frequently with customers as we can, and go through scorecarding with them. Ownership fosters long-term relationships. Mack strives for long-term partnerships, and we avoid doing anything for short-term financial gain that might negatively affect a long-term customer relationship.

CA: What are the metrics you use?

WK: On the tactical side, customer metrics focus on execution, like on-time delivery; return material authorization (RMA) turnaround; quality – yield at customer site, returns, internal DPMO; availability of quality info, such as frequency and accuracy; flexibility – we let the customer dictate that; for every customer it’s different. We define flexibility as “changes to the steady state of business.”

We design a supply chain to fit the customers’ inventory management and needs.

Moreover, compensation has been tied to profits and customer satisfaction since the inception of Mack Technologies. If you concentrate on something long enough, it becomes part of the culture. It’s part of the belief system of the team.

CA: Is the scorecard-related compensation substantial?

WK: The maximum payout can be a significant portion of an employee’s compensation. The formula was developed about 25 years ago, and the axes sometimes change, but the internal payout rates have been consistent.

CA: Does Mack approach its suppliers with the same level of detail?

WK: Our supply base is a major factor in our performance for our customers.

JK: We’re demanding but fair, and view (the supply base) as a long-term extension of our own capabilities.

CA: Are the metrics qualitative or quantitative?

WK: Some of the qualitative things include asking customers to rank us against our competitors. This is a major factor in our analysis. We ask if their view of us is favorable or not.

Quantitative metrics are rolled up and put into an algorithm, and weighted with qualitative metrics. It’s a homegrown formula that has existed for quite awhile. We also push for the qualitative aspects. The typical scale is 1 to 5. (For the internal scale, it’s 0 to 100). The score goal is aggressive and consistent year-to-year.

CA: One of the problems in a long-term customer relationship is that mistakes are bound to happen. How do you avoid those mistakes from building up to the point where, in the customer’s eyes, you have become an inferior supplier?

WK: What separates companies in terms of customer perception is how you react to mistakes to ensure the same mistake never happens again. Are you implementing procedures to minimize the impact and ensure they don’t happen again?

JK: I think quality reviews help keep that on balance. If you continue to meet with their senior executives and objectively review performance data, you establish credibility and can view the overall performance in context of the whole relationship, as opposed to a specific instance that may be more emotionally memorable, but overall insignificant in the greater scope of the relationship. At the end of the day, what matters most is our longstanding execution and performance for our customers.

WK: With quality business reviews, it helps both companies look at all the data for a given period, instead of just the performance for the immediate short-term period leading up to the review.

CA: How do you ensure the Mack approach can withstand the loss of key personnel?

JK: The systems are well-designed, so that if we lost key members of the staff, the system would survive. Then it’s a level of discipline. All three sites [Ed.: Mack has facilities in Massachusetts, Florida and Mexico] meet one to two times each week. There are monthly performance data meetings. The system is simple to understand. Sales and operations talk across all three sites.

CA: How do you ensure the Mack culture during the hiring process?

JK: Internal management has been in place for a long time, so there’s mentoring. We try to vet the employee recruiting process, so we can find the right people for the task. We look at their background. Mentioning only “profit” without also mentioning customer satisfaction and service is a red flag. We look for candidates who talk about the customer.

CA: Besides the program managers, who within Mack is allowed to engage with the customers?

JK: Quality, Materials, Test, Finance and Operations. The majority of people with access to communications are allowed and encouraged to talk with customers. The program manager is always involved in the communication too.

Meetings are generally by phone or onsite, depending on the customer location. We like to see the customers in person when it makes sense.

CA: Say you attained the corporate goal in a given year. Now what do you do?

JK: We don’t stop once we achieve the goal. When your performance is good, you are establishing credibility. Over time, we strive to further enhance our performance – even when we have set a high watermark for expectations from our customers. If you are missing 20% of your metrics underperforming, the relationship isn’t going to go anywhere.

WK: Customers tell us when they think we aren’t performing. This openness and honest communication really only works when the customers feel comfortable that they can tell us where we can improve and that we will constructively receive the feedback. We have a flat management team. There are not many people our customers have to call in order to get an answer. Information usually can be transferred quickly because we are flat. Our structure enables a level of communication that some others might not have.

JK: I think your reputation becomes critical in the sales cycle.

CA: What is the program manager’s role in all this?

WK: The manager is responsible for ensuring staff is following through. It comes from the top and flows to the whole team. All feedback is shared with teams, so there’s a lot of formal feedback.

JK: We use the same scorecard across the company, so when we hire a PM, it’s a critical part of their training. And we launch programs to address problems and bad trends, e.g., RMA.

‘Flexible, But Diligent’

"A good, seasoned team of professionals that offers a lot of industry knowledge when you need it."

That’s how customers see Mack Technologies. As part of this reporting, Circuits Assembly spoke with a pair of Mack customers: Thomas Kokernak, director of global supply chain management at Kopin Corp. (kopin.com), an OEM of ultra-small LCDs and heterojunction bipolar transistors for consumer, industrial and military applications, and a Mack customer for almost three years; and Glenn Cozzens, vice president of engineering, operations, and information technology at ThingMagic (thingmagic.com), a developer of RFID technology. (Cozzens has outsourced to Mack at multiple employers.)

CA: What services does Mack provide you?

GC: Printed circuit board and box-builds. Mack does the parts procurement through functional test. What we call a box-build is really a small reader, like a router. These are RF devices. Mack also manages the material required from other suppliers.

TK: Mostly manufacturing, but when needed they can perform environmental test and can support various other things such as manufacturing solutions for coatings and boards. They also offer us higher-level manufacturing services like component procurement. We are leveraging some of [Mack’s] Florida asset capability for some of our customers. From quality perspective, they are serving us in both locations, as some of our customers are near their Florida site. The other thing I like is the parent company [Mack Group] has molding capability, so if I wanted to bring them a box-build program, they span the network of what I would need done. And they have prototyping capability.

Why do they make us happy? The quality is good, even first time out the door. Mack is very flexible and very responsive, but diligent in making sure documentation is in place.

CA: How do you typically communicate with them?

GC: We do a hybrid. As head of engineering and operations, I talk to Will Kendall. Our test engineer talks to their test engineer. Our process engineer talks directly to their process engineers and program manager. We go there regularly and have weekly meetings. We use email, phone, text and electronic transfer of data.

TK: Through the program manager, or engineers talk to engineers. The relationship is such that it’s not unusual for our engineers to say they are going to talk to Mack’s.

CA: How have you handled quality issues?

GC: When we run into a manufacturing defect – and everyone has them – we formally request a corrective action. First, we want to see a containment measure, in order to prevent more failures from making it out. Then we work on root cause. Of all the CMs I’ve worked with, they are the best at diagnosing failures on the line. Sometimes the corrective action is on their side, like a process change or a footprint change; sometimes our tester didn’t find something that needs to be corrected.

TK: If there is a quality issue, they are very responsive. In some cases they have helped with quality issues with our customers. We’ve also used them for training our lab workers for soldering to IPC standards.

CA: Do you have specific metrics for grading its suppliers?

GC: ThingMagic uses on-time delivery, cost, quality. We do post-pack audits where we retest 10% of the deliveries we receive. If one fails, we send the whole batch back for retest. After-market, we monitor dead-on-arrival rates and infant mortality rates.

TK: Kopin uses a supplier performance review whereby quality is 45%; supply chain is 40%, and technical, meaning engineering services, is 15%.

CA: How does Mack grade?

TK: In the high 90s.

CA: How does Mack rate among your EMS providers?

GC: I think they are the best we have. We have three CMs that build PCBs and assemblies. By doing that [having multiple suppliers], we ensure competitive bidding. What we do over time is whoever rises to the occasion gets the project. Usually, that is Mack.

TK: We also have a couple small ones. Mack would be at the front of pack. For the military environment I’m in, they are who we rely on.

Mike Buetow is editor in chief of Circuits Assembly (circuitsassembly.com); mbuetow@upmediagroup.com.