Soured by Graping Issues?

Novel solder paste formulations overcome miniaturization challenges.

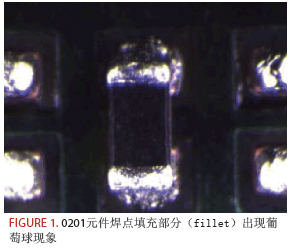

The electronics industry’s never-ending miniaturization quest has constantly challenged conventional processes, forcing solutions to problems that are a direct result of the move to such tight geometries. At the board level, it’s safe to say that a large majority of these issues have to do with the deposit volumes required to achieve high-integrity solder joints for such small components. So, the soldering process – from print through reflow – is front and center. Arguably, however, the move from 0402s to 0201s (with 01005s soon to follow) and from 0.4 mm CSPs to 0.3 mm CSPs into more mainstream production has made some issues even more severe. In fact, this downward trend in pitch dimension has even revealed a new phenomenon not seen before and one that is directly attributable to severe miniaturization: graping.

Graping, as the name implies, is a grape-like cluster formation of partially coalesced solder spheres that make up the solder joint after reflow. Why does this occur? Not only do smaller solder paste deposit volumes call for thinner stencils, more thorough release and smaller solder spheres within the paste material, these necessary miniaturization conditions are also pushing the solder particle surface area to flux ratio to a breaking point. In addition, the surface area to volume ratio of the smaller deposit increases the relative level of surface oxidation.

The primary function of flux is to permit soldering by removing any surface oxides that may be present on metals – including the solder spheres within the paste. The flux will also protect those spheres from re-oxidizing during the reflow process. The move to smaller particle sizes rapidly increases the total metal surface of the solder, requiring more activity. Likewise, smaller deposits will have a higher surface area to volume ratio as compared to larger solder deposits. Since the majority of the powder oxidation is on the particles on the deposit surface, increasing the relative amount of deposit surface increases further the demands on the flux. When the flux can no longer remove the surface oxide, which melts at a higher temperature, then flux exhaustion happens and graping occurs.

A solder material that may reflow very well on 0402s or a 0.5 mm CSP can be significantly challenged on small deposits because there is so much additional powder oxidation due to the increased deposit surface to volume ratio that the flux activity becomes depleted. In these situations, full coalescence does not occur and graping is the result.

Solder paste suppliers address graping through a novel activator chemistry. This helps alleviate the problem in a number of ways. First is ensuring better release from the stencil and more even deposits, thus minimizing the surface area to volume ratio of the deposit. Second is controlling the powder particle size distribution by designing a solder paste that incorporates advanced powder technology. Improved particle size distribution delivers both a reduced metal surface and an optimal deposit surface area to volume ratio. Third is formulating the flux so that it has both sufficient activity and the ability to minimize re-oxidation of the powder, thus overcoming the graping as it occurs. In other words, the flux not only has to reflow nicely on the large deposits, but it also has to be able to remove existing oxides and protect all of the metals from re-oxidizing.

Jie Bai is a chemist at Henkel Electronics Group (henkel.com); jie.bai@us.henkel.com.