Impact of Mesh Size and Stencil Technology on Deposition Volume

Paste chemistry and rheology have a more profound effect on release than previously thought.

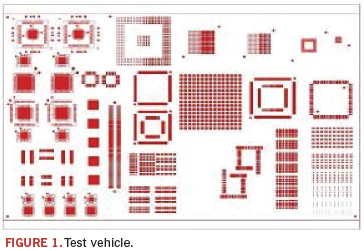

PCB assemblers are reaching the limits of Type 3 solder paste. The goal of this study was to determine the impact on solder volume deposition between Type 3, Type 4 and Type 5 SAC 305 alloy powder in combination with stainless steel laser cut, electroformed and the emerging laser cut nano-coated stencils. Leadless QFN and µBGA components utilizing optimized aperture designs were the focus of the test. The test procedure evaluated pause-to-print and volume transfer efficiencies on 20 boards over an 8 hr. period. A concurrent study using the same boards evaluated the impact of powder particle size on voiding of QFN ground pads testing 18 different aperture designs.

With components such as QFNs, µBGA and 01005 passive devices with small lead areas and corresponding pad geometries, it is possible that Type 3 solder paste is too large to permit accurate and repeatable solder paste deposition. This issue impacts all facets of the manufacturing process, not just the solder paste used when assembling such components to a PCB.

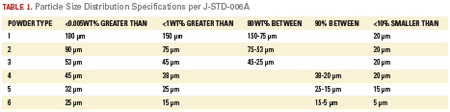

It has been an assumption that the smallest aperture solder paste can pass through repeatedly is five times the largest sphere size of the metal powder. In Type 3 powder, the average sphere size is 45 µm, with allowances to 53 µm. Theoretically, an 0.0089" aperture is the minimum aperture that can be printed with Type 3 solder paste (Table 1).

Moreover, there are myriad aspects when considering the proper stencil design for a given assembly. For the purposes of this experiment, the goal was to minimize the variables to ensure the results obtained reflected the aspects under our control.

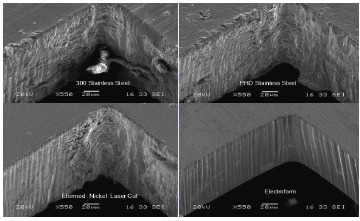

Electroformed nickel stencils (e-form) provide the taper, wall smoothness and lubricity that lend to the best paste release characteristics. However, they are significantly more expensive than traditional laser-cut, electropolished stencils and may not be as readily available. Laser-formed stencils are a relatively new option. These stencils are cut using upgraded lasers in combination with high nickel content foil materials. They represent an improvement over standard laser-cut stencils at a lower cost than e-form. These two technologies were used in this experiment.

Finally, an emerging technology termed “nano-coating” has been made available in some markets. This technology and process are largely proprietary, but the process is described as:

“After the brushing and cleaning operation, the laser cut stencil runs through a special designed coating machine. The inorganic coating is dissolved in a very environmentally friendly solvent. The constant thickness of the nano coating is the key technology of the coating process. In a continuous furnace the coating is dried out, and a multiple stage heat treatment polymerizes the dry inorganic layer. In the same equipment, a chemical reaction with an organic chemical is carried out to provide the hydrophobic anti-adhesion properties.”1

The main function of the coating is to reduce the surface tension between the paste and stencil material. A reduction in surface tension creates a non-stick surface, facilitating better paste release, resulting in more consistent paste volume deposits and less residual paste in the aperture, thereby aiding in volume deposition accuracy in subsequent print cycles. A stencil identical to the laser-formed stencil was nano-coated using Laser Job in Germany and included in the experiment. Aperture designs were optimized for paste volume deposition.

Stencil specifics:

- PHD stainless steel.

- Thickness tolerance is +/-3 or 4%.

- Hardness is 370 HV min.

- Flatness: max. edge wave 1.5 mm and max. center wave 0.50 mm.

- Grain size typically 10-25 µm.

A fiber diode type laser was used to cut the stencils. It was a gantry-style motion system with 10 nm resolution and 0.5 µm repeatability. Operation and connections were auto-focus. The laser was a 150W Class I fiber laser system, air-cooled, with permanent align beam delivery and compressed air cutting.

Experiments were conducted at AIM’s Montreal Production Simulation facility using a DEK 265 GS printer, a Quad QSP IV placement machine, a Heller 1500 reflow oven and Koh Young KY3020T SPI.

The lab process was as follows: The temperature was 22° to 23°C with 24 to 26% RH. A 12" squeegee was used, with a squeegee pressure of 0.8 lb. and speed of 1"/sec.

Materials used included:

- No-clean SAC 305 T3 Solder Paste A.

- No-clean SAC 305 T4 Solder Paste B.

- No-clean SAC 305 T5 Solder Paste C.

- No-clean SAC 305 T3 Solder Paste D (modified for better printing).

- No-clean SAC 305 T3 Solder Paste E.

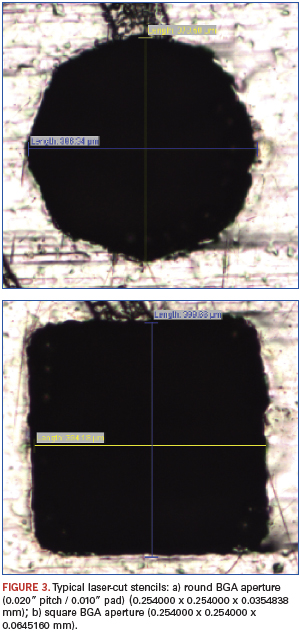

- BGA stencil (0.005" laser cut) (Figure 3).

- QFN LGA Stencil (0.005" laser cut, 0.005" electroform, 0.005" nano-coat, 0.005" nano-coat laser cut, 0.005" proprietary coated laser cut).

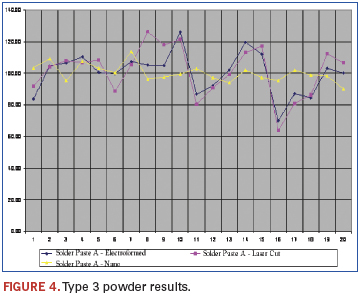

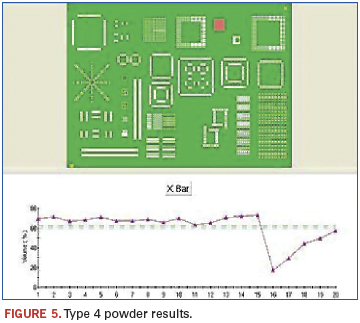

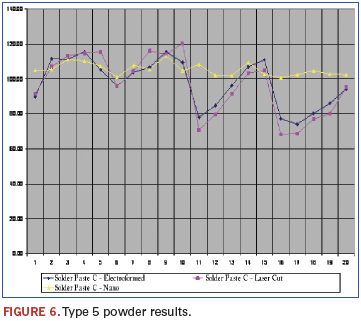

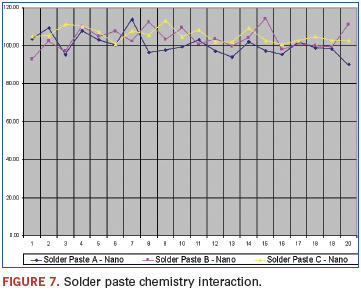

Test method. The test method was developed to simulate a low-to-mid-volume production environment with pauses between print cycles at regular intervals. Volume and height measurements were taken immediately following completion of printing of the test board. Boards 1 to 5 were printed and measured, and the process paused for 30 min. Boards 6 to 10 were printed and measured, and the process paused for 60 min. Boards 11 to 15 were printed and measured, and the process paused for 90 min. Boards 16 to 20 were printed and measured (Figures 4-7).

Solder paste/chemistry observations. The results indicate that neither mesh size nor stencil type have a significant impact on the volume of paste released from the stencil aperture (uncoated stencil). The paste deposit may have a different appearance visually between types, but the critical measure of volume is unaffected.

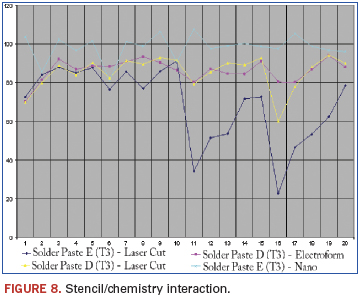

This was somewhat surprising, as it was believed that e-form stencils and paste manufactured with Type 4 powders would provide the most consistent paste release characteristics. To further develop the data, an additional variable was introduced to determine the impact of paste chemistry on the deposition volume. A developmental solder paste material was introduced to the experiment for comparison and the following results obtained (Figure 8).

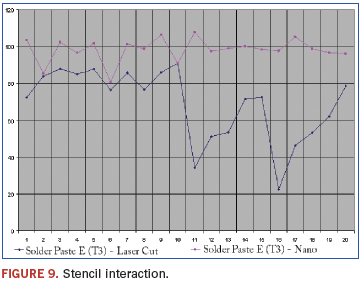

As evidenced by the data, paste chemistry/rheology has a more profound effect on release characteristics than either stencil or powder mesh size (Figure 9).

The impact of nano-coating on the release characteristics of solder paste from stencil apertures was the single biggest variable in improving release volume consistency.

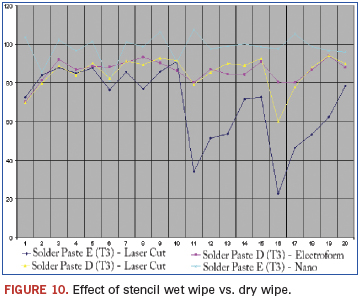

Testing was performed with the addition of a solvent deemed compatible with the paste chemistry in use to assess the impact on the release characteristics. It was found the addition of a solvent to the underside wipe cycle of a stencil printer has a moderately positive effect on the release volume of the paste from the stencil aperture (Figure 10).

Conclusions

The variables that have the most significant impact on paste release on fine-pitch apertures are listed below in order of significance:

- Stencil type (nano).

- Paste chemistry/characteristics.

- Stencil wipe (solvent wipe compatible with paste).

Nano-stencil technology has a profound impact on the performance of paste release. This is an emerging process with many competing technologies under development.

Following nano-coating, paste rheology and chemistry are areas of continued development by solder paste manufacturers. Pb-free solder pastes are still relatively new in comparison to their leaded predecessors, and continued improvements are expected as the technology matures.

The introduction of solvent to the printer stencil wipe process is a relatively inexpensive process improvement with few negative side effects, assuming the material is deemed compatible with the solder paste in use. Based on these findings, it can be inferred that stencil design and materials have a far greater impact on release characteristics than paste powder mesh size.

Karl Seelig is vice president, technology and Tim O’Neill is Northeast regional sales manager at AIM Solder Products (aimsolder.com); kseelig@aimsolder.com.