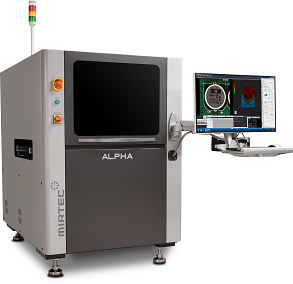

MIRTEC Introduces Alpha 3-D AOI

Alpha 3-D automated optical inspection system is configured with hybrid 3-D inspection technology that provides uniform precision measurement across 3-D measurable range, regardless of external factors such as PCB density and material characteristics.

Reportedly yields superior edge definition and requires substantially less software filtering of raw inspection data. Automatic programming software uses AI-based deep learning methodology to minimize human error and standardize programming process. Automatically analyzes PCB architecture and assigns appropriate part type and process parameters for each SMT device. Optical character recognition technology reduces false calls and improves production process efficiency by automatically restoring and inspecting damaged characters through AI and deep learning. Total remote management system combines remote management with real-time data monitoring and analysis for each system within SMT production line. Provides real-time remote monitoring of status information and statistical data, such as equipment operation status, production yield, PC resources, temperature, humidity, etc.

MIRTEC

mirtec.com