PCB Laminate Cracking

Brittle materials can lead to CAF failures.

Brittle materials can lead to CAF failures.

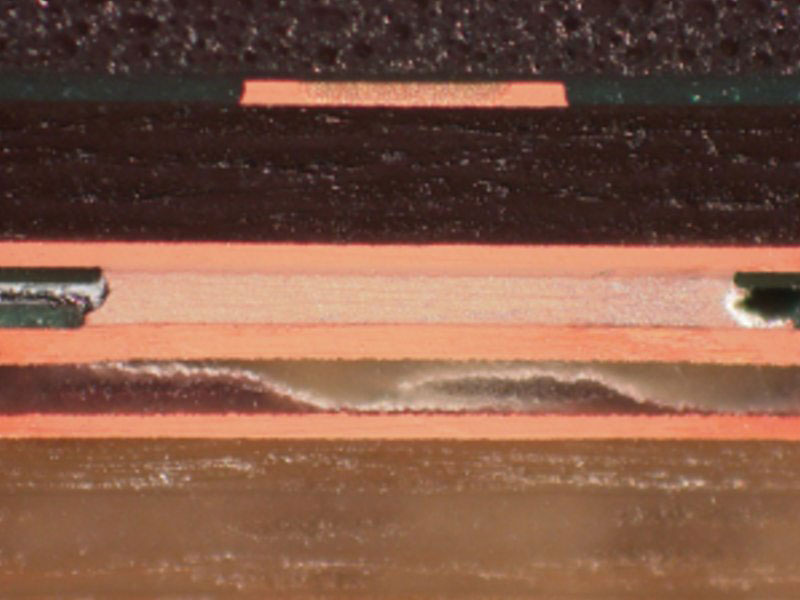

CRACKING OR SEPARATION of laminate has been seen on some base materials during and after the introduction of lead-free. Experience shows some materials are brittle, leading to the epoxy cracking, which is one of the causes of pad lifting on BGA packages. We have also seen evidence of this failure during flexure of boards or during drop testing, again more likely with certain laminates.

Any cracking or separation of the glass and the epoxy in the laminate can lead to conductive anodic filament (CAF) failures. CAF basically is a lowering of the insulation along the path of the crack or separation. Detailed reports on the formation of CAF and some methods of preventing this failure mode are available from the NPL Defect Database.

These are typical defects shown in the National Physical Laboratory’s interactive assembly and soldering defects database. The database (http://defectsdatabase.npl.co.uk), available to all this publication’s readers, allows engineers to search and view countless defects and solutions, or to submit defects online. To complement the defect of the month, NPL features the Defect Video of the Month, presented online by Bob Willis. This describes over 20 different failure modes, many with video examples of the defect occurring in real time.

Figure 1. Laminate cracking, as shown here, is more typical on some laminates than others.

Figure 2. Cracking can lead to various failures, including CAF.