Metric 0201 Assembly: A Holistic Evaluation

In the first of two parts, our columnist looks at the printability of Type 5 and 6 pastes.

In the first of two parts, our columnist looks at the printability of Type 5 and 6 pastes.

In understanding the dynamics of reliably assembling metric 0201 components, an analysis of all key process steps – printing, placement and reflow – is required. While effective printing is central to the success of steps down the line, the reality is that with dimensions this small, the integrity of all elements is critical. With this as the backdrop and informed by previous analysis of metric 0201 printing, our company engaged in comprehensive evaluation of metric 0201 assembly, beginning with printing and the most viable materials for the job. This column will present findings on the stencil printing investigation, and, in a departure from the normal “printing” focus, the next column will reveal the placement and reflow study results.

To begin, we wanted to gain an appreciation regarding the effectiveness of certain solder paste materials. In full disclosure, this was not an exhaustive evaluation of multiple solder paste suppliers’ materials. Rather, our team selected two suppliers and three materials with which we have had past success. This is an important point, as not all materials are created equal and, in evaluating Type 5 and Type 6 solder pastes, it is imperative manufacturers test them under specific manufacturing conditions with specific tool sets, as all variables play a role in performance.

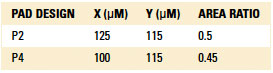

For this analysis, we used Supplier A Type 5 paste and Supplier B Type 5 and Type 6 pastes. The test board was an ASM test vehicle for metric 0201 and metric 030105 evaluation. The board contained an array of different patterns and two different pad designs of 100µm x 115µm and 125µm x 115µm, respectively, with three different component pitches of 100µm, 75µm and 50µm. The stencils were 60µm thick, standard stainless steel stencils with a nanocoating. With these dimensions, area ratios were at or past the recommended IPC limit at 0.45 and 0.50 (TABLE 1). Primarily, our applications engineering team wanted to understand how the materials released, printed and how robust and resistant the pastes were to bridging. Process parameters were optimized for each paste, and 14 boards were run for each of the three pastes. The fifth board and last board in each run were inspected to assess the stability of the process.

Table 1. Pad Designs and Corresponding Area Ratios

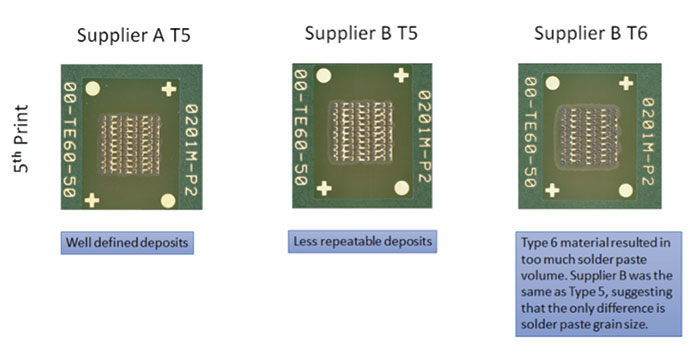

The Supplier A Type 5 solder paste resulted in less variability when printing the small 0.45 area ratio aperture design. Almost immediately, it was observed a material diversion was occurring and not all solder pastes perform similarly. Although logic would suggest a Type 6 solder paste with very fine particle sizes might be the best candidate for the job because of the miniaturized component and pad dimensions, our results revealed otherwise. While the printer capability ensured the paste was deposited centered on the pad, volumetric measurements showed the Type 6 material had wet print bridging; it was over-printing. When working with other components such as BGAs, for example, the process might be a bit more forgiving with the Type 6 materials. But, when there are only two component terminations and a device that doesn’t have much height or weight, the material volume deposited on the two pads is critical. As for the Type 5 materials, they also differed in performance, which underscores the importance of evaluating various pastes, as not all Type 5 materials are necessarily compatible with metric 0201s (FIGURE 1).

Figure 1. Printing capabilities observed with various pastes and suppliers.

The analysis confirmed it is possible to repeatably print through 60µm stainless steel foils for metric 0201s using a Type 5 material. The process and materials exist today. The second part of the evaluation investigated metric 0201 placement and reflow process capability, the results of which will be shared in our next column.

Like any process variable – and there are a gracious plenty of them with the printing operation – one can’t assume the solder paste material or even the solder paste brand used today will be compatible with next-generation technology. Every material is different, every process and application unique, and every result distinct. Join me here next time and find out what happened with metric 0201 placement and reflow.

is global applied process engineering manager at ASM Assembly Systems, Printing Solutions Division (asmpt.com); clive.ashmore@asmpt.com. His column appears bimonthly.