Flux-Crazed Solder Mask

To err is human; to blame the other vendor is … policy

Nearly every process engineer has found themselves in this quandary: something goes awry with the process, and the supplier finger-pointing begins immediately. With machines, chemistry, components and PCBs all factoring into the mix, it often appears that a supplier’s first line of response is to deflect responsibility rather than help seek the root cause. Chemistry providers don’t have the luxury of suggesting a few mechanical measurements or a quick check under the hood to rule out our products as the source of problems, so we are accustomed to rolling up our sleeves and helping solve them.

We occasionally field calls on solder mask crazing, delaminating or peeling after wave solder. Solder mask problems are not uncommon at all, and we’ve certainly seen our share over the years. Nearly all solder mask delamination is PCB-related, not flux- or equipment-related. If solder mask is visibly damaged after soldering, it likely has adhesion or cure problems, or perhaps a combination. Here are a few simple tests the engineer can do on the shop floor to help zero in on the root cause:

Adhesion checks.

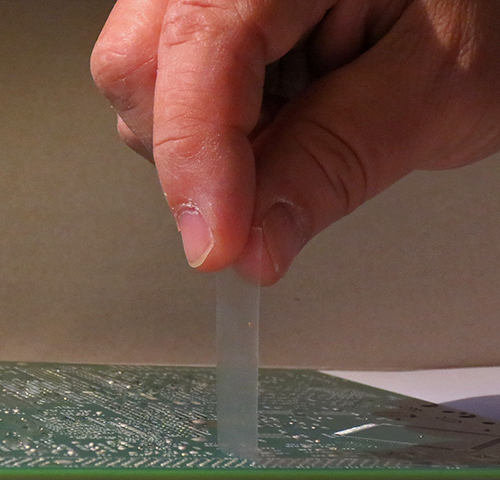

- The tape test. Apply a piece of transparent adhesive tape from your desktop tape dispenser; press at least a 2" length on the board and pull it up quickly, at an angle approximately 90˚ to the PCB surface (FIGURE 1). If the tape pulls the mask off, you are looking at an adhesion problem. The official IPC test method (IPC-TM-650, 2.4.28) calls out 3M Brand 600 ½-inch (aka “Scotch”) tape, but if that’s not what’s in your dispenser, use whatever is there.

- Keep looking. Observe the condition of the copper under mask that has lifted. If the copper is shiny, it was likely not properly prepared for solder mask application. A matte finish indicates proper cleaning and roughing of the surfaces before mask application. A shiny finish indicates inadequate preparation.

Figure 1. If mask comes off during the tape test, it’s an adhesion problem.

Cure checks.

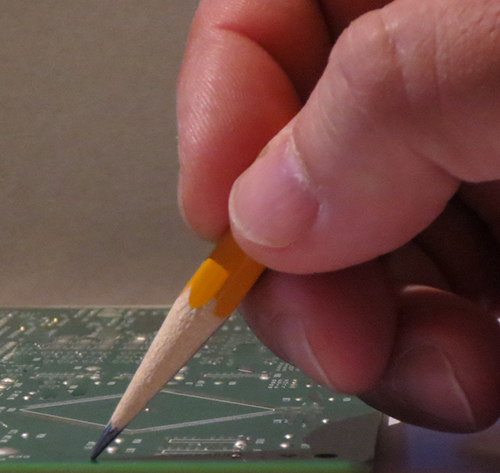

- The pencil test. Locate a wooden pencil and give it a fresh sharpening. Hold it at a 45° angle and press firmly away from you (FIGURE 2). If the solder mask lifts or gouges, it’s not fully cured. The pencil used was likely a #2H (we’re all familiar with those from standardized tests). Pencils are graded on a hardness scale, and any graphite grade less than #6H should not gouge solder mask. A #6H pencil, or a complete kit of varying hardness pencils, is sold at art supply stores.

- The solvent test. Get some MEK (methyl ethyl ketone), available in your chemistry lab, machine shop or local home improvement store, and a cotton swab. Swab the solder mask in question, and if any color comes up on the swab, the mask is not fully cured. Be careful with the solvent: glove up, don’t inhale it, and don’t forget the MSDS.

- The bake test. Put a specimen in a 160°C oven for 30 min. and then retest it. If the problems go away, the mask was likely undercured, and the bake helped finish the cure. If the mask still exhibits an issue, it may be the mask chemistry itself was not properly prepared and is a potentially catastrophic failure waiting to happen. This is a very rare but serious occurrence.

Figure 2. The pencil test indicates whether mask is fully cured.

In our experience, solder mask problems typically stem from application issues; the mask chemistry itself must meet an IPC spec (IPC-SM-840) and is pretty robust. I compare it to house paint: even if you use the best paint in the world, you are going to suffer substandard results if you don’t follow the surface preparation, application and drying time recommendations.

We recently tackled a solder mask problem that actually was partially flux-related. In this case, a liquid flux was interacting with solder mask and making it appear hazy and crazed, even lifting it from the substrate. The issue appeared to happen most frequently and severely around traces. A review of the wave solder process indicated no unusual steps, parameters or exposure times that could cause solder mask damage, and the PCB fabricator insisted it was a flux problem.

We asked the user to perform a few of the simple solder mask tests while we researched the flux lot number to see if there were any production changes or other customer concerns associated with it. We found no changes or concerns on record, but this particular flux was a highly specialized, small-batch material. We theorized that perhaps some variations could have taken place within its shelf life, so we tested a sample sent back from the user. We found nothing there either – yet another hypothesis nullified.

Meanwhile, the mask failed both the peel-and-look and swab tests. This information helped the assembler demonstrate the solder mask problem to its PCB fabricator and drive a resolution. In our investigation of the mask and flux chemistries, we discovered that the mask was a newer, halogen-free product. If not properly cured, one of the solvents in the flux could potentially attack it. So in this particular case, we concluded the flux definitely could contribute to the mask attack, given the deficient mask condition. When the solder mask application problems were resolved, so were the crazing and delamination problems.

It’s not unusual for the solder chemistry vendor to drive the root cause analysis of soldering issues. In fact, it makes perfect sense. The soldering technical support staff sees so many varied and different processes and problems. They are natural troubleshooters and a great resource for process engineers. Plus, you can’t take a caliper to a glob of gray, goopy paste or look under the hood on a bottle of flux. Proper evaluation of material performance often relies on tests borne from the cause-and-effect knowledge that is only gained through experience.

A quality vendor should not attempt to pass the responsibility for process issues down the line, but rather commit to leading the customer to the fastest, most effective solution, regardless of fault. The “pass the buck” strategy can backfire and jeopardize business; yet, for some inexplicable reason, it is still commonly deployed. Until it’s eradicated, keep calling the soldering guys; much of our valued experience is acquired through our customers’ challenges.

Au: Many thanks to our colleague Gerard O’Brien of ST and S Group for technical guidance on solder masks and problem troubleshooting.

is vice president of technology at AIM Solder; kseelig@aimsolder.com. is technical marketing manager at AIM; toneill@aimsolder.com.