The Balancing Act

In search of the perfect solder paste. (Hint: It's a moving target.)

Solder paste – that ubiquitous, viscous, sticky blob that is applied as the first step of every SMT assembly process – is a surprisingly complex product. It is composed of two primary constituents: solder powder, which accounts for 85% to 90% by weight or 50% by volume, and flux medium as the balance. As complicated as powder development and manufacturing can be, flux medium is even more so, due to the myriad demands and constraints placed on it.

Imagine you are planning a big party and you decide to make the aptly named Patience Cake (FIGURE 1) – arguably one of the most complicated baked goods recipes imaginable. Different batches of batter must be mixed in advance, refrigerated overnight and baked in individual pans. Pieces of the baked goods are then precision cut, and evenly applied layers of icing must buffer the different cake pieces to form an aesthetically pleasing design. It’s an exacting process but not an impossible one. Now, let’s increase the complexity and imagine you have to make a dozen of them exactly the same way, which is daunting but still manageable … until you find your new mother-in-law is a gluten-free, nut-free, egg-free vegan!

Figure 1. Patience Cake.

The development and manufacture of solder paste is analogous to the Patience Cake. Like the individual cake layers, solder paste has a multitude of properties that must be intricately balanced and buffered, and like your new mother-in-law, each assembler has a set of unique requirements. Solder paste properties are generally categorized as reliability, printability, reflow performance, residue characteristics, environmental initiative compliance and operational requirements. A change in one property may complement or conflict with one or more other properties, and the interactions make for an intense balancing act.

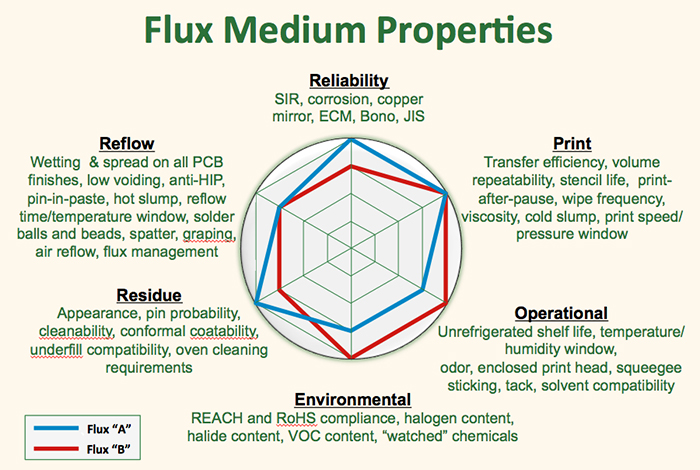

To aid in visualizing these complex interactions, the radar chart shown in Figure 2 enumerates the key flux properties within each category. With over 45 typical considerations, and often additional customer-specific criteria, striking the best balance in a flux formula requires some forethought to get the right fit for both the assembly process and the product’s end use. Radar charts help illustrate the balances that have been achieved for any given flux formula and enable users to easily compare the performance of multiple products.

Figure 2. Radar chart of flux medium properties.

Balancing 45-plus characteristics is challenging because certain flux medium properties often contradict each other. Activity and residue characteristics are prime examples of the tradeoffs made by developers and users. High-activity flux is always preferable because it accelerates oxide reduction on difficult-to-solder surfaces to produce stronger, more mechanically sound solder joints. Higher activity is usually achieved by increasing the ionic content of the flux medium, which often compromises electrochemical reliability. Activity and reliability are almost always at odds with each other.

Activity and paste stability are another common tradeoff. Nudge flux activity up too far and the flux will start acting on the powder particles’ surface oxides as soon as the two components are blended, which can lead to more inconsistency in storage tolerance, and can potentially affect print and reflow performance as well. On average, a solder paste medium consists of 15 to 25 ingredients that must not only remain harmonious within themselves, they must also coexist with the metal powder and its vast surface area until processed through the reflow oven – at which time our focus immediately shifts from activity back to electrochemical reliability.

The “perfect” solder paste would have high-activity and high SIR values, be environmentally friendly, provide best-in-class printing, exhibit high tack, produce low-voiding, prevent head-in-pillow, be pin probable, exhibit room-temperature storage stability, and be a readily cleanable no-clean. It would also be chemically and physically impossible. But optimized solder pastes aren’t out of reach; in fact, there are plenty available in the marketplace. Different applications prioritize different properties, which is why so many different flux mediums exist in the first place – and why users need to understand the balancing act to make informed decisions about their soldering chemistry.

When selecting a solder paste for general use or specific applications, users should consider the different solder paste properties and prioritize the most important characteristics. As examples, highly miniaturized assemblies need excellent print characteristics and sometimes underfill compatibility; designs with many BGAs or BTCs require robust reflow properties; pin-tested PCBs demand easily penetrable flux residues; high-reliability boards must often be cleaned or conformal coated, and the list goes on. In addition to key performance characteristics, the production environment should be considered. If operation-specific process deviations such as temperature and humidity extremes, shipment delays at customs or in receiving, or extended times between printing and reflow are present, they should be discussed with the supplier and factored into the test protocol to ensure the best fit product is selected.

When selecting solder pastes, process engineers often set up test methods, evaluation criteria and weighted scorecards to rank the performance of individual products on a data-driven basis. Here are three tips for a successful evaluation plan:

- Focus on the most important properties. Don’t waste time or money testing for basic characteristics. Most modern solder pastes perform well in general categories; no suppliers are going to waste their time or money introducing products with known major deficiencies. Instead, they optimize for key properties while keeping the others acceptable.

- Make sure to incorporate usage environment factors but do so reasonably. Setting up tests at absolute extremes that are not indicative of typical usage may actually overshadow more important factors. It’s better to set test conditions within a reasonable, typical process window.

- Discuss specific performance needs and usage environment with the supplier before selecting the test candidate. No one knows solder pastes better than those who make it, and nobody sees more varied applications and uses than the technical support staff. Odds are they have encountered similar requirements, constraints and operating environments and can provide professional advice based on your specific needs.

The best solder paste is the one that satisfies the mission of the assembly and the needs of the assembler using it, even as those needs change over time. Solder paste developers are continually innovating to meet the evolving demands of the marketplace. And as with the Patience Cake, an obsessive attention to detail and a deep understanding of current and future needs can make even the most complex balance seem effortless.

is technical marketing manager at AIM; toneill@aimsolder.com. is vice president of technology at AIM Solder; kseelig@aimsolder.com.