Unforgiving Environments

Proper handling and storage controls go a long way toward print quality.

Solder paste is an elaborate mixture of metal powders, acids, thixotropes, solvents and a variety of other chemicals. When combined, the reactions and interactions can be extremely varied and complex. When designing solder paste chemistry, key considerations include not only its in-process performance but how to maintain the stability of that performance against the rigors of time, temperature fluctuations and usage.

Stencil printing is arguably the critical process on the assembly line because it lays the foundation for the entire assembly. A quality print does not necessarily preclude rework, but a bad print effectively guarantees it. Additionally, the PCB assembly process is vulnerable to external influences, such as operating environments, setup changes and operator variability. A key parameter for solder paste is to introduce a minimum of variability into the manufacturing process.

Any inconsistency in paste performance can produce unwanted outcomes down the assembly line.

During product development, solder pastes are characterized against typical time, temperature and usage conditions to ensure product stability. But their performance can be profoundly impacted by influences beyond the developer’s lab. Consistent solder paste functionality on the production line relies on a robust chain of custody from raw materials to the stencil printer. Any break in that chain can adversely impact performance.

The first link in the chain is the manufacturing process of the solder paste and its constituent materials. Powder is manufactured and stored under tightly controlled conditions. (See “The Balancing Act,” CIRCUITS ASSEMBLY, August 2015).

Flux medium raw materials require controlled storage, and the flux medium is also produced under tightly controlled conditions, with an abundance of quality control measures. The slightest anomaly in flux production can generate unacceptable results on the customer’s assembly line. The powder and flux medium are blended in an exacting process, after which responsibility for minimizing variability begins to shift from the paste manufacturer down the chain to packaging, shipping, distribution and the end-user.

Solder paste packaging is a labor- and materials-intensive process. Solder paste is kept cool, and environmental exposure is limited to a few seconds – from the time the container is filled until the plunger is placed in the jar or the cap is screwed onto the cartridge. It is then packed in carefully engineered packaging designed to keep the product cool for at least 30 hr. to cover typical transit times.

Solder paste must not be exposed to elevated temperatures; otherwise, the material may not arrive fully intact and will not perform as designed. Increased temperature increases the chemical interactions within the solder paste that adversely impact every aspect of its performance. These changes may initially be subtle and then worsen over time, making them even more insidious than if the paste had arrived in an obviously unusable condition. Minor variations can lead to increased voiding, decreased wetting, clogged apertures and other process variations, forcing engineers to make adjustments to address faltering print quality, declining end-of-line yields, or both.

Solder paste is most likely to experience temperature extremes in transit. According to Federal Express, summer temperatures in the cargo area of ground vehicles can reach 30˚F higher than the ambient temperature outside the vehicle. To illustrate the point, in Phoenix, one of the hottest cities in the US, temperatures regularly exceed 100°F (38˚C), peaking at 116˚F (47˚C). Using FedEx’s guidelines of +30˚, conditions can climb to 146˚F (47˚C). This will certainly cause some interactions, and may have already activated some of the oxide-reducing agents in the solder paste, literally forcing the paste to interact with itself. Even International Falls, MN, one of the US’s coldest cities, experienced several 90˚ days this summer. This means unprotected paste could experience temperatures as high as 120˚F (49˚C), a temperature engineers often use to “cure” prints for SPI golden boards.

Shipping cannot only heat the delicate cargo; it can freeze it. Fedex says temperatures aboard most wide-body aircraft main cargo compartments vary between 65˚F (18˚C) and 90˚F (32˚C). Meanwhile, packages in the bulk department, adjacent to the aircraft’s outer structure, might be exposed to in-flight temperatures as low as 0˚F (-18˚C).

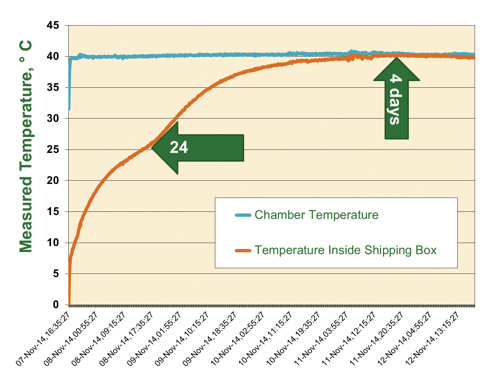

These conditions require extensive measures to ensure the carefully developed and manufactured solder paste arrives at the customer’s site with the least amount of shipping-induced variability and performs as designed. FIGURE 1 shows the internal temperature of the shipping container when placed in a thermal chamber for five days at 104˚F (40˚C).

Figure 1. Five days shipping test (container placed in thermal chamber at 40˚C) for solder paste.

The final link in the transit chain is the end-user. We can safely estimate that over three-fourths of solder paste handling-related issues occur after delivery to the end-user. Here are some basic tenets for using and handling solder paste:

- Store paste per manufacturer recommendations (usually refrigerated) immediately upon receipt. Although boxes are clearly marked with labels indicating the need to refrigerate upon receipt, receiving dock employees should be trained to identify these packages and move them into proper storage as quickly as possible. Most freight carriers can set up automatic tracking updates to alert engineers or operations personnel when paste arrives on the dock.

- Mark and log each paste container for when it was put into storage and when it was removed for use. Practice FIFO rigorously.

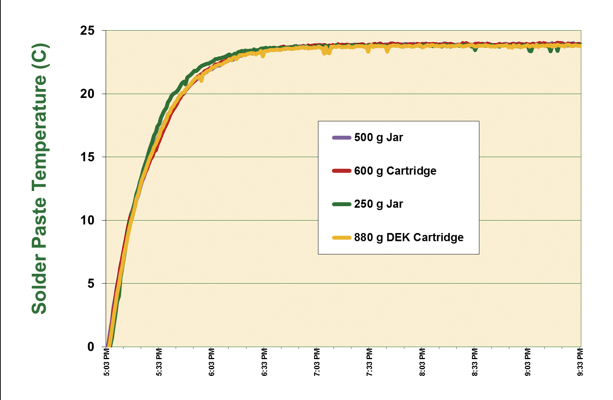

- Permit paste to warm to ambient temperature naturally. Do not force warming by placing the paste on or near a hot machine surface and do not open the jar. Solder paste that is below the dew point of the manufacturing area will condense moisture. When moisture is added to the metal and chemicals that constitute solder paste, the performance will degrade. FIGURE 2 shows the warming time from refrigerated to ambient in an air environment.

- Stir paste packaged in jars per manufacturer’s recommendation. Cartridges do not require stirring, as the paste is shear-thinned during dispensing. Solder paste is a thixotropic material; as such, when mechanical energy is introduced, the viscosity drops. As the energy dissipates, it will thicken. Stirring ensures the material is ready to print when applied to the stencil and redistributes material that may have settled.

- Never mix used solder paste with unused solder paste. Contaminants from the used paste will compromise the unused material with adverse effects. When one considers the investment required (upwards of $500,000) to set up and run an SMT production line, it is shocking to see the lengths to which some assemblers go just to save a few grams from a $50 jar of solder paste. The cost/benefit relationship is wildly askew.

- The production environment is also paramount to process stability. Ideally, the production floor will be 72˚-80˚F with RH of 40% to 50%. However, geography, seasonality and facility capabilities are often beyond the control of the engineer. Selecting a solder paste that performs well in select manufacturing conditions is key to successful outcomes, as described in this space in the aforementioned August 2015 column.

Figure 2. No-clean SAC 305 solder paste warming time.

While solder paste is a seemingly mundane gray blob, it is actually quite the opposite. It is the foundation for an extremely complex process that must perform without issue, in all climates, on all surfaces with all types of equipment. Manufacturers go through great pains to develop, produce and deliver products that meet all their clients’ needs. One of our customers described solder paste in a way that really accentuates its importance: “I’m not printing circuit boards. I’m printing money … and solder paste is the ink. When the ink is bad, I can’t print money, and then the importance of the material becomes very obvious.”

is technical marketing manager at AIM; toneill@aimsolder.com. is vice president of technology at AIM Solder; kseelig@aimsolder.com.