Key Factors Affecting Printed Circuit Board Cost

Think ahead, because the cost of a PCB is essentially designed into it.

Think ahead, because the cost of a PCB is essentially designed into it.

The many different factors and variables of producing PCBs complicate the task of estimating the cost to manufacture them. Considerations for the cost factor depend primarily on the different production strategies manufacturers use, the varied production equipment employed, and the range of technologies available for creating the final product.

Regardless of the factors responsible for the cost buildup, it is critical to control costs in the early stages of the PCB design process. This is because the cost of a PCB is essentially designed into it, and it is impossible to reduce it later without redesign. Although additional process steps do add to the associated cost in terms of materials, consumables, process times, waste treatment, and energy, the process cost impacts the PCB price regardless of the manufacturer.

Accurate costing in PCB fabrication depends on several factors. These include the complexity of the board, the raw materials used, the production equipment, and the overall efficiency of the process. Cost factors may be divided into three categories to facilitate classification. Note that cost factors related to Categories II and III depend on the equipment used for fabrication and are therefore specific to the manufacturer.

Category I (Significant Cost Factors)

The key factors (and others) that contribute to the cost in Category I include:

PCB size. This is a simple linear equation, with the cost increasing linearly with the size of the PCB.

Yield (i.e., effective utilization of board material). Unless the PCB is excessively large, manufacturers can fit several pieces on a panel. Usually, panels are vendor-specific and come in standard sizes, including 18" x 24", 18" x 21", or 21" x 24". Utilization depends on the area of the panel used for PCBs, with 77% and above qualifying as good utilization. For high-volume production, panel utilization becomes a critical aspect with respect to PCB cost.

Number of layers (layer count). This is a simple equation, with the cost increasing with the number of layers. Usually, more layers translate into additional cost due to more production steps, more material, and additional production time required. This is not a linear increase, however. For example, converting a single layer PCB to two layers may increase the cost of the PCB by 30 to 40%, whereas adding two additional layers to a 10-layer PCB might increase the cost by only about 20 to 30%. This cost factor also depends on the complexity of the PCB design and differs from manufacturer to manufacturer.

The reverse, however, does not work in a linear fashion. Reducing layer count does not always reduce overall cost, since doing so could involve more complex technology and aggressive design practices, both of which affect yield. If complexity and design remain constant, however, a change in cost of the PCB corresponds proportionally to its layer count.

PCB complexity. PCB complexity depends on the number of layers and the number of vias in each layer, as this defines the variations in layers where the vias start and stop, requiring so much more lamination and drilling steps in the PCB manufacturing process. Manufacturers define the lamination process as pressing two copper layers and dielectrics in between adjacent copper layers using heat and pressure to form a multilayer PCB laminate. Since via structures have a major effect on the manufacturing process, fabricators optimize costs by using microvias and HDI technology. Not only does HDI reduce overall costs by decreasing the number of layers, it also makes the PCBs smaller lighter, and thinner, while providing superior electrical performance.

Materials used. Selection criteria for materials used in fabricating PCBs depend on several application-based factors, defined mainly by frequency, speed of operation and maximum operating temperature. These factors include thermal stability, temperature-related reliability, temperature cycle reliability, heat transfer rate, time to delamination, and many others. In fact, the higher the frequency of operation or speed of the signals, the more important the choice of materials. For example, compared to conventional FR-4, polyimide increases cost by approximately three to five times, and PTFE-based microwave materials may inflate cost nearly 10 to 50 times.

Category II (Important Cost Factors)

Although cost factors involving Category II greatly depend on the PCB manufacturer, some important ones include the following:

- Track and gap geometry (thinner is more expensive);

- Control of impedance (additional process steps increase costs);

- Size and count of holes (more holes and smaller diameters drive up costs);

- Plugged or filled vias, and whether they are copper-covered (additional process steps increase costs);

- Copper thickness in the layers (greater thickness means higher costs);

- Surface finish; e.g., the use of gold and its thickness (more material and more process steps increase costs);

- Tolerances (tighter tolerances are more expensive).

Category III (Minor Cost Factors)

Minor cost factors defined in Category III depend on both the fabricator and application of the PCB. They mostly involve the following:

- PCB thickness;

- Various surface treatments;

- Solder mask;

- Legend printing;

- PCB performance class (IPC Class II/III, etc.);

- PCB contour, specifically for z-axis routing; and

- Side or edge plating, if any.

For accurate cost estimation, experts (including us) recommend taking an existing design scope and making adjustments to the requirements based on estimated technologies. Such estimates offer more relative data points for making cost decisions. The estimates also prevent later surprises in the process once resources have been committed to a design.

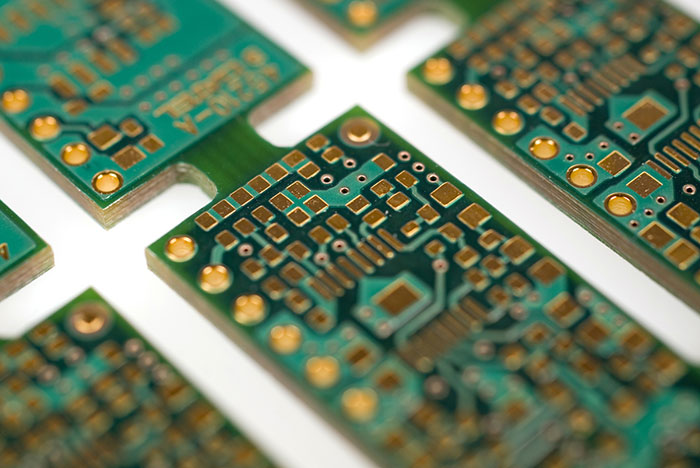

Figure 1. Surface finishes can appreciably change the board cost.

is chief executive officer of Rush PCB, a printed circuit design, fabrication and assembly company (rushpcb.com); roy@rushpcb.com.