PCB Panelization Costs: It’s All About the Real Estate

Just like housing, a little extra size can cost a lot more.

Printed circuit boards in panel or array format increase the efficiency of the assembly operation, especially in volume applications. Takt time is greatly reduced, and handling of product is easier. However, rising material prices are cutting into that advantage because more material is required to produce those arrays.

PCB costs are based on the amount of raw material required to make a particular board. The metal finish, like ENIG or silver, plays a part in pricing, but it is the amount of fiberglass and copper needed that really determines the final cost.

The quoted price for most boards in panel or array format is based on a fabricator's desired panel price for a particular technology or quantity, divided by the number of arrays (or pieces) that fit on a standard 18 x 24" manufacturing panel. The more arrays or pieces that fit on the panel, the lower the cost.

Whether that price is dictated by the number of boards (arrays) that can fit on the standard manufacturing panel, or by the total square inches of the finished array, a quarter or half-inch too long in one direction may mean a double-digit price difference.

That price difference is a double-edged sword: Either the board eats into profits because it is costlier to buy, or it’s a missed sales opportunity because the board could have been quoted at a lower cost.

I have seen inefficiently panelized PCBs so many times. Sure, there is always some waste in manufacturing, but how much money is the contract manufacturer throwing away on every assembly?

Maybe that board does need a full inch of material railing on all four sides for it to be assembled, but it’s worth asking whether that was the original array when the assembly was still in its prototype stage. Could it be it was never optimized for production? Did anyone bother to ask?

Buyers who want better panelization pricing must ask:

“Do we have to have railing on all four sides?”

“Does the railing need to be that wide?”

“Can we score instead of route?”

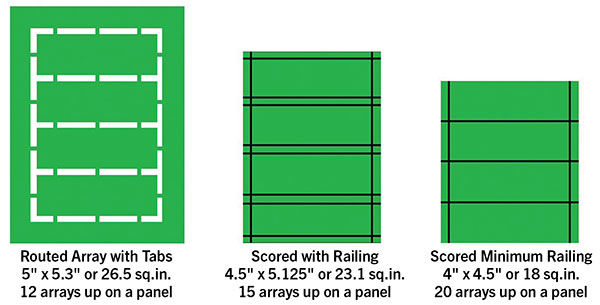

FIGURE 1 shows a PCB placed in an array in one of three configurations, revealing the cost difference realized when the right questions are asked.

Figure 1. A PCB in one of three configurations. Less real estate equals savings.

The tab-routed array on the left with a large railing on all four sides is the least cost-effective design, yielding only 12 arrays per manufacturing panel.

The design in the middle has a much thinner railing, but still on all four sides, with scored spacing in between the boards instead of the route. That half-inch difference in one dimension makes all the difference, permitting 25% more: 15 arrays total per panel.

The design on the right is the most cost-effective, where the PCBs are “butted” up against one another, and just two thin rails are needed along the longer edge. Eight more arrays (a 75% increase) are available from that same manufacturing panel compared to the routed array.

Depending on the board manufacturer, square inches of the finished product can also be used to calculate pricing, especially for larger volume orders, and this illustration holds true for that method as well. Fewer square inches mean a lower cost per array or piece.

Sometimes larger railing is needed, especially if a particular assembly requires something special. An example is a component that overhangs the edge of the board and requires extra spacing. In that case, the PCB buyer’s engineering department should let purchasing know of any special requirements prior to sending them to the fabricator for a quote.

Additionally, board buyers need to talk to their production and engineering departments and ask for a company standard for assembly criteria that can be incorporated into PCB fabrication specs.

Ensure your PCB suppliers have those specs in hand, so the quotes they submit meet your assembly criteria without adding unnecessary costs or delaying quote response times.

The wasted green I see on the production floor is not solder mask. It’s dollars. PCB buyers need to see that too.

has more than 25 years’ experience selling PCBs directly for various fabricators and as founder of a leading distributor. He is cofounder of Better Board Buying (boardbuying.com); greg@directpcb.com.