News

White Residues: Are They or Aren't They?

When it comes to white residues, a defect is not always a defect.

IPC-A-610D, section 10.4.3, states that white residues are considered a defect for class 1, 2 and 3 hardware when:

White residue is on the PCB surface.

White residues is on or around the soldered termination.

Metallic areas exhibit crystalline white deposit.

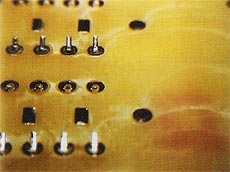

FIGURE 1: White residue on an assembly (source: IPC-A-610D). |

An additional note states that white residues resulting from no-clean or other processes are acceptable provided the residues from chemistries used have been qualified and documented as benign.

We are asked repeatedly whether a white residue is a defect. Our answer is always, “It depends.” A white residue cannot be judged solely by appearance and type of assembly process used, but instead needs to be investigated to determine the makeup and potential effects on reliability. These answers are found through good testing protocols. Ion chromatography with localized extraction of white residue areas will identify and quantify residues present in the areas of concern, and act as an indicator as to the performance effects caused by the residues. A followup investigation with SIR testing will examine tangible long-term effects of white residues on reliability if left on the board.

To differentiate the various scenarios in which white residues occur, and whether they should be classified as benign, here are typical situations encountered with water-soluble and no-clean processes. White residues almost always come from flux residues on boards. What determines whether the residues are detrimental is the type of flux chemistry they stem from and the underlying cleanliness of bare boards and components. Over the years, Foresite has written a battery of case studies exemplifying the various scenarios in which white residues occur, and whether they are a detriment to product performance. In July 2004 (“Is White Residue a Reliability Risk?”), I discussed the appearance of white residues on no-clean assemblies. White residues on a no-clean assembly can be considered benign provided they are fully heat activated and there are no residues from incoming bare boards and components.

Visible white residues in a water-soluble process are a more telling sign. These residues almost always come from remaining flux reacting with moisture during cleaning to create a visible white residue. Flux activators found in water-soluble fluxes have potential to be highly conductive and corrosive if not cleaned and rinsed appropriately. They are not intended to remain on the board, and if a visible white residue occurs, it is an indicator that enough flux remains to cause problems. These residues could prove to be detrimental; to combat them, modify cleaning protocols to ensure that the water-soluble flux residues are driven off.

The final scenario to watch for white residue involves the soldermask. Sometimes there will be the appearance of a white residue hazing, a sign of undercured soldermask. The effect of this is the base pulling away from the epoxy. The soldermask itself can also have a white appearance and become lifted due to delamination.

Do not make a ruling on whether a white residue is a defect per IPC specifications until proper testing and verification has been performed. As the examples above prove, there are more than enough scenarios to warrant investigation into what the sources and effects of the white residues are.

Terry Munson is with Foresite Inc. (residues.com); tm_foresite@residues.com. His column appears monthly.