2005 Articles

Pb-Free, Moisture Sensitivity and X-Ray Inspection

While seeing MSD popcorning may be difficult, x-ray can catch its other effects.

|

|

So you have decided to dip your toe, or perhaps dive headlong, into the alligator-infested waters of Pb-free assembly? Hopefully by this time you have selected a Pb-free paste, modified your wave-solder pot to prevent catastrophic leaks and added extra support to prevent the board from dipping into the wave because of the increate operating temperature. Yes?

You have probably spent a lot of time optimizing a new, higher temperature reflow profile for your oven. Your operators have been retrained to understand that a dull joint is, in fact, a good joint and does not need touchup. Your AOI system failure responses have been reprogrammed to accept the look of the new Pb-free solders, right?

You have learned (and are no longer angry to know), that around 60% the components you have been buying for years already have Pb-free terminations, even if your supplier never told you. And you are successfully managing your remaining inventory of leaded and Pb-free components – if you can tell which are Pb-free and which are not.

You have acquired and read the recently released IPC-A-610D1 and IPC-7095A2 documents your customers are now specifying. And finally, you have attended conferences covering the changes Pb-free will bring and listened to the expert advice given by consultants and your suppliers. With all the blood, sweat and tears you have already invested in the change to Pb-free, what could possibly still bite you on the behind?

How about the moisture sensitivity of components, especially area array packages such as BGAs? Do you realize that MSD levels will change when your process changes to Pb-free?

With the peak body temperature of components potentially reaching 250°C during Pb-free reflow, components will be more susceptible to moisture. This problem has been clearly identified in many papers presented at conferences and in reference documents (for examples, see the Cogiscan MSD Knowledge Base3).

In particular, it is suggested3 that under Pb-free reflow conditions the moisture sensitivity of components may increase one to three levels and will require reclassification by the component manufacturer. This could mean, for example, that the components you have been using with an level 3 (168 hrs., per Table 1) may now be Level 5 (48 hrs.), or worse. Before rushing into Pb-free processing, you must reclassify MSDs in your storeroom and on the floor, if necessary.

The difficulty with BGAs is that although they tend toward greater moisture sensitivity, seeing the detrimental effects (often called “popcorning”) via optical methods following reflow is not possible.

At this point x-ray inspection becomes crucial. Popcorning results from moisture trapped within the BGA turning to steam during reflow. As the moisture (steam) gains volume, the BGA expands and the package pops, often fracturing, delaminating or cracking the internal component. While these effects may not be seen clearly during x-ray inspection, what will be seen, quickly and easily, is the effect of popcorning on the solder balls of the BGA.

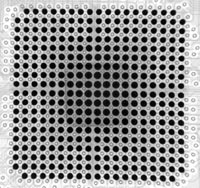

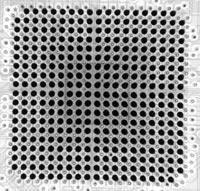

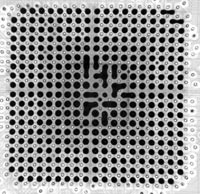

As the package expands it presses down on the solder balls, enlarging their diameter (Figures 1 and 2). Following reflow, the solder balls retain a larger diameter than would normally be expected after cooling. It is also likely that bridges between solder balls will appear with more frequency (Figure 3).

One more thing to worry about? Perhaps. But reconsidering the moisture sensitivity of your components in line with manufacturer recommendations for Pb-free profiles when coupled to x-ray inspection should at least help to prevent nasty bites.

References

- IPC-A-610D, Acceptability of Electronic Assemblies, February 2005.

- IPC-7095A, Design and Assembly Process Implementation for BGAs, October 2004.

- Cogiscan MSD Knowledge Base, cogiscan.com.

- IPC/JEDEC J-STD-020B, July 2002.

David Bernard, Ph.D., is product manager, x-ray systems, at Dage Precision Industries (dage-group.com); d.bernard@dage-group.com.

Press Releases

- Federal Electronics Expands Nearshore Capacity with Additional PCBA Line in Hermosillo

- Mexican Electronics Manufacturer Improves PCB Reliability with I.C.T Conformal Coating Line

- Cape EMS Unveils ‘CEB 2.0’ Roadmap to Drive High-Value Tech and Infrastructure Growth

- ECIA Calls for Tariff Stability as New Global Trade Framework Takes Effect

FIGURE 1: Popcorned BGA with central solder balls larger in diameter than the outer balls.

FIGURE 1: Popcorned BGA with central solder balls larger in diameter than the outer balls. FIGURE 2: Good reflow of BGA.

FIGURE 2: Good reflow of BGA. FIGURE 3: Bridging of solder joints after popcorning of BGA.

FIGURE 3: Bridging of solder joints after popcorning of BGA.