2005 Articles

Mixed Metallurgies

Can SAC-finished components be soldered with SnPb? Sometimes.

Within a two-week period, the EMPF (Electronics Manufacturing Productivity Facility) Helpline received four calls asking whether it is possible to solder, using SnPb, a component with a SnAgCu finish and whether there are reliability concerns. The EMPF has investigated Pb-free finishes used by component manufacturers. The predominant finish of choice is tin, because the tin-plating process is identical to that of SnPb. However, tin-finished components are susceptible to tin whiskers, a major hardware reliability concern.

As an alternative, component manufacturers are considering other alloys. SnAgCu is an attractive choice for SMT components because this alloy was selected by several consortia as the preferred solder alloy for reflow soldering.

One caller said they would be using SnAgCu-finished chip components with eutectic SnPb solders and questioned whether this presented a reliability risk. SnPb solder has a melting temperature of 183°C. A typical reflow soldering thermal profile for SnPb solder has a peak temperature of approximately 220°C, which is only slightly higher than the SnAgCu alloy melting point of 217°C. A typical profile for SnAgCu solder would have a peak of about 240°C. However, during reflow, the peak temperature is usually held between 30 and 90 seconds due to the chip components’ relatively low thermal mass; therefore, the chip components are above the melting temperature for both solder alloys. In this case, both SnPb and SnAgCu should form an acceptable solder joint.

The other callers were using SnAgCu-finished BGA packages with eutectic SnPb solders and again questioned the reliability risks. EMPF staff consulted one of its Industrial Advisory Board members, who encountered this scenario during a recent component qualification test sequence. Again, a typical reflow soldering thermal profile for SnPb solder has a peak temperature of approximately 220°C – just above the 217°C melting point of SnAgCu and less than the recommended peak temperature of 240°C for this alloy.

Unlike the chip components previously mentioned, the BGA package has a high thermal mass, which inhibits heat transfer. There is also a high SnAgCu solder volume in the solder balls, which inhibits solder joint homogenization. This prevents the BGA’s SnAgCu solder balls from melting and collapsing. At best, parts of the ball may enter the “pasty” range, where they are beginning to melt, but there is not sufficient heat to melt and collapse the entire solder ball.

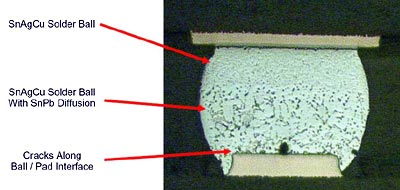

A microsection of the solder joint was performed to determine what was happening inside the solder ball (Figure 1). Analysis revealed that the SnPb solder paste had only diffused from the ball/board pad interface into the bottom third of the BGA’s SnAgCu ball, rather than all the way through the ball.

FIGURE 1: SnAgCu BGA ball soldered with SnPb solder.

FIGURE 1: SnAgCu BGA ball soldered with SnPb solder. |

Also observed were distinct areas within the SnAgCu ball where the solder microstructure and intermetallic phases changed, indicating that the top of the SnAgCu solder ball was cooler than the bottom. The high thermal mass of the BGA package acted like a heatsink, causing temperature differences within the solder ball.

To confirm the hypothesis that this situation creates a non-reliable solder joint, thermal cycling was performed from -55° to 125°C. After approximately 250 cycles, the solder joint failed. When examining the failed joint, a large crack was found at the ball/board interface.

The results of the investigation showed that when manufacturing with chip components finished with SnAgCu metalization and using SnPb solder paste, users should ensure that the thermal profile reaches at least 220°C to properly form the solder joint. However, when building assemblies with area array packages containing SnAgCu balls with SnPb solder paste, using a typical SnPb solder profile will result in an unacceptable solder joint. This combination should be avoided until further failure analysis is completed.

Au.: The author would like to acknowledge the contributions of D. Hillman of Rockwell Collins and A. Campuzano-Contreras of BAE Systems.

Lee Whiteman is a senior engineer at ACI (aciusa.org); lwhiteman@aciusa.org.

Press Releases

- News Zollner Continues to Expand Capabilities in Thailand

- Keiron Printing Technologies Appoints PIT Equipment Services to Support Revolutionary LiFT Technology Adoption

- Surf-Tech Manufacturing Adds New ViTrox V510i AOI to Strengthen Advanced Packaging Inspection

- Altus Supports Cambertronics’ SMT Process Upgrade with Koh Young SPI