GHS Impacts on the EMS

How environmental management systems will change under the new OHSA requirements.

The Occupational Safety & Health Administration (OSHA) has adopted new chemical labeling and material safety data sheet (MSDS) requirements during its recent update of the Hazard Communication standard 29 CFR 1910.1200. The latest revision brings the HazCom standard into alignment with the United Nations Global Harmonized System (GHS). The standard requires pictograms be conveyed on new labels to alert the user of chemical hazards and precautionary statements. In addition, material safety data sheets (MSDS) will be replaced with the term “safety data sheet” (SDS). The new GHS label will become a subset of the SDS, which provides a complete detail of chemical hazards in a new standard format. The major impacts to an environmental management system (EMS) will be training, safety data sheets and chemical labeling.

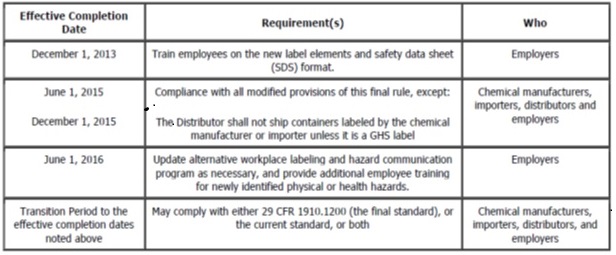

Here we discuss the practical impacts of the GHS standard on a company’s EMS (environmental management system), given a facility’s requirement for chemical management. Deployment and compliance of the new regulation will be introduced over the next few years, with the major impact of the standard felt by chemical manufacturers, given their responsibility to change to the new GHS label and SDS format. Table 1 lists requirements of the new GHS hazard communication standard.

Table 1. GHS Compliance Summary from OSHA.

(Source: OSHA.gov, Hazardous Communication - HazCom (Hazard Communication) standard 29 CFR 1910.1200)

GHS training. The initial target date of Dec. 1, 2013, requires employers to train employees on the new label elements and SDS format. The GHS will change the content of a company’s annual hazardous communication (HazCom) training, given the updates to standard 29 CFR 1910.1200. The training target date was set to Dec. 1 because chemical manufacturers have started to transition to the new GHS standard.

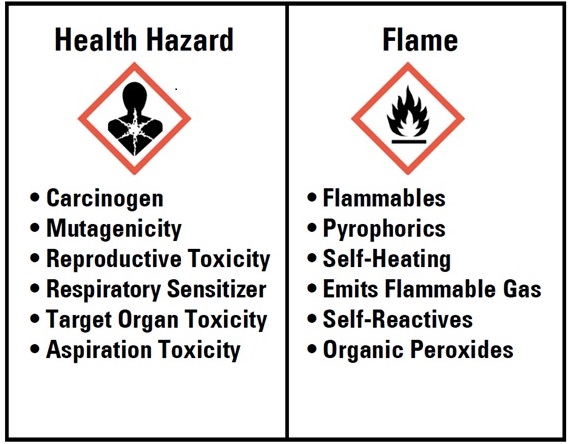

Minimum requirements are outlined by OSHA, which entails training on the labels such as product identifier, signal word, pictograms, hazard statements and precautionary statement. Figure 1 shows examples of two new pictograms. A total of eight pictograms have been adopted, which represents the individual hazard for the specified chemical.

Figure 2. Two of the eight pictogram symbols. (Source: OSHA.gov, Hazardous Communication - HazCom (Hazard Communication) standard 29 CFR 1910.12000)

Practical examples should be given for specific chemicals and the associated hazard pictogram and potential signal words. Choose specific chemicals that are often used within the facility and present the new GHS label for that chemical. Review each section to provide an understanding of the standard, including hazardous and precautionary statements.

The second part of training will be the new format for the safety data sheets (SDS). The new hazardous communication standard has defined a 16-section template that will require all chemical manufacturers to provide chemical data in the same format. A recommendation during the new training session is to provide a practical example of the new SDS format for an often used chemical within the facility. Review and highlight some of the pertinent sections that may include chemical makeup, first-aid measures, storage recommendations and exposure control/personal protection. Samples of the new GHS labels and safety data sheets can be found on the OSHA website.

EMS impacts – the transition. A part of most environmental management systems is chemical management, given its environmental impact and aspect. The transition to the new safety data sheets will require companies to catalogue and make available to all employees the new SDS and resulting standard format. The new labeling standard will be provided on chemicals by the original manufacturer. If a facility transfers the chemical into a secondary container, this will be required to be labeled also with the original hazard information. Depending on size of the container, various tools can be used, such as placards or signs that link the label and hazard information to the specific chemical. To support the new GHS standard, frequently audit the facility to ensure chemical labeling is compliant to the new regulation, legible and present. Labels that are not legible must be replaced, as these provide the hazardous and precautionary statements to all employees. Verify chemical storage to local, state and federal regulations that may include separating flammable and corrosive chemicals.

Chemical handling and personal protective equipment. The introduction of any new chemical should include a review of the SDS and any supporting documentation that can provide the reviewer with an understanding of the chemical hazards, emergency precautions, and, most important, exposure controls and personal protection. One recommendation is to have a cross-functional team review each new chemical and investigate the impacts to the environment, health and safety for the facility. The main goal of the chemical introduction is to ensure the safety of all employees and that no impact will be on the environment.

After a chemical has been approved, PPE (Personal Protective Equipment) and specific chemical handling instructions may be required. It is important to communicate these requirements, which in their absence may increase chemical exposure limits. In addition to communication, deployment into a work instruction or procedure will ensure standardization.

Some chemicals determined by their hazard review or employee health reaction may require exposure limit monitoring. This monitoring can be accomplished by different methods, such as air or work surface analysis, depending on the exposure. Once completed, compare the results to limits provided by the chemical manufacturer’s safety data sheet or to state, local or federal regulations, if required.

Summary

The change in the hazard communication standard will impact all industries that use chemicals within their facilities. The standard will be transitioned in phases with the initial compliance date of Dec. 1, 2013. By training employees to the new GHS standard, all involved will understand chemical hazards and how to protect employee safety and the environment.

Scott Mazur is environmental management representative and manufacturing staff engineer supporting ISO 14001 and various environmental programs for Benchmark Electronics New Hampshire Division; scott.mazur@bench.com.

Press Releases

- Federal Electronics Expands Nearshore Capacity with Additional PCBA Line in Hermosillo

- Mexican Electronics Manufacturer Improves PCB Reliability with I.C.T Conformal Coating Line

- Cape EMS Unveils ‘CEB 2.0’ Roadmap to Drive High-Value Tech and Infrastructure Growth

- ECIA Calls for Tariff Stability as New Global Trade Framework Takes Effect