Zooming in on Digital Microscopes

Why high-def displays are replacing eyepiece lenses for close-up views of PCBs.

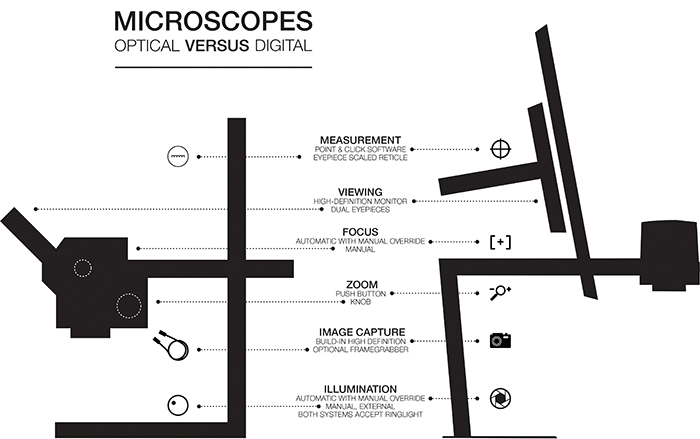

The digital revolution has come to visual inspection of printed circuit boards. Traditional optical microscopes used to inspect PCBs for over half a century are being replaced with high-resolution cameras, high-definition monitors and user-friendly interfaces. What’s behind the mainstreaming of digital microscopes on shop floors and laboratories around the world? The biggest drivers are image quality, ease of use and measurement capability.

- Image quality has taken a giant step forward thanks to CMOS technology. The camera sensor, a CMOS chip, dictates the digital image’s resolution and color quality. The pixel count of the sensor determines the resolution of the final images. High-definition (HD) sensors capture 720p images with resolution of 1280x720 pixels, whereas full high-definition (FHD) sensors capture 1080p images with resolution of 1920x1080 pixels. Advanced digital microscopes provide live video of 60 frames per second, or 60Hz. The high frame rate creates outstanding live images without any perceptible distortion. The image’s color intensity, brightness and contrast all depend on the CMOS chip’s sensitivity to light and its signal processing firmware.

At any given magnification level, digital microscopes usually have larger fields of view (FoV) than optical microscopes, enabling the inspection of more components at one time in a single FoV without needing to move the specimen under the lens. - Ease of use has also greatly benefitted from the digital migration. Auto-focus and auto-exposure technologies borrowed from point-and-shoot cameras enable anyone to capture a high-quality image with the touch of a button, no training required. The digital auto-focus function presents a considerable time-saving advantage over the manual focusing of optical microscopes when changing magnification levels. On digital microscopes the automatic features can be manually overridden to tweak settings for special purposes such as oblique angle viewing or capturing markings on tall components. Also, digital magnification systems offer programmable preset magnification remove line, add a space and exposure settings to ensure consistent viewing among different operators and in documentation photos.

Viewing images on a monitor while sitting or standing has numerous ergonomic advantages compared to leaning over an ocular lens, as it reduces strain and fatigue on the neck, shoulders and eyes. Ergonomically speaking, it is much easier to obtain an optimal working position with a monitor than with eyepieces. Additionally, digital microscope/monitor systems enable simultaneous viewing by multiple people, making it easier to point out areas of interest, eliminating the need for viewers to switch positions at the scope and refocus each time. They also eliminate the spread of illness and viruses via shared eyepieces.

Digital microscopes capture images on an SD card or on a PC. The SD capability is good for quick image sharing or if the system is used without a PC. If the digital microscope is connected to a PC, the images are saved on the computer’s storage drive or to a network drive. Features of captured images can be precisely measured using dedicated software.

- Measurement capability adds a wealth of functionality to digital magnification systems. Taking measurements involves pointing the mouse and clicking its button; gone are the days of squinting through reticules and counting crosshairs. Most digital microscopes will measure basic geometric figures, such as distances, angles, radii and areas. Measurements are displayed on the monitor and can be notated on captured images. Other notations, such as specifications, can also be displayed along with the measurements.

In addition to the performance gains, digital microscopes are cost-competitive. Acquisition costs of digital equipment are typically lower than those of comparable quality optical microscopes, and they require little, if any, maintenance. There are no eyepieces to get scratched or damaged, no gears to strip, and no opportunities for dust accumulation to detract from picture quality. Factory utilization rates tend to be higher than that of optical models because they are used more frequently and often shared among multiple departments.

Optical microscopes will never go extinct; they will always have their place in electronics inspection. Certain specimens or subjects that require depth perception are better viewed optically, and many optical systems offer an option of digital image capture. For the majority of the microscopy needs on shop floors, however, digital imaging alone is a faster, easier, more cost-effective means of visually inspecting circuits.

If a picture is worth a thousand words, a live high-definition video or high-resolution still is priceless, especially when inspecting small devices, producing documentation or describing problems to multiple viewers simultaneously – even those connected remotely via the Internet. The digital revolution has expanded the role of the traditional microscope in electronics inspection by adding new capabilities and applications. The simplicity and effectiveness of modern digital imaging technology are now enabling better communications among coworkers within departments, companies and supply chains.

Figure 1. A comparison of digital and optical microscopes.

is founder of Shea Engineering Services (sheaengineering.com); chrys@sheaengineering.com. is electronics segment project manager for Tagarno (tagarno.com/electronics). Contact ; sam@tagarnousa.com.

Press Releases

- PulseForge Makes Major Breakthrough Which Allows Flux-less Soldering in an Ambient Environment

- Panasonic Connect publishes case study on delivery of its surface mount technology (SMT) equipment to Dixon Technologies, one of India’s largest EMS companies

- CE3S and Desco Industries Announce May 2026 ANSI/ESD S20.20-2021 Certification Webinar Series

- Kurtz Ersa Goes Semiconductor: Expanding Competence in Microelectronics & Advanced Packaging