Online Bath Monitoring

A major OEM equipped the cleaning baths at two production plants with measuring systems for continuous bath monitoring. Here’s why.

To meet the requirements of optimum industrial component cleanliness and surface treatment, cleaning baths, degreasing cascades, rinsing baths and coating processes are monitored online along the entire process chain. Spray or immersion baths are used to remove contamination or to apply anti-corrosion coatings. To monitor the process, these baths are equipped with analytical measuring systems that determine the concentration of the cleaning agent or anti-corrosion agent inline. In addition, the degree of contamination can be analyzed directly in the bath in order to ensure efficient bath maintenance. In PCB production, the cleaning process is an important step to remove residues of flux, resin or soldering paste. PCBs need to be cleaned reliably; otherwise electrical failures or component corrosion might occur. To ensure the maximum lifetime of the products, the concentration of the cleaning bath is continuously monitored directly in the process.

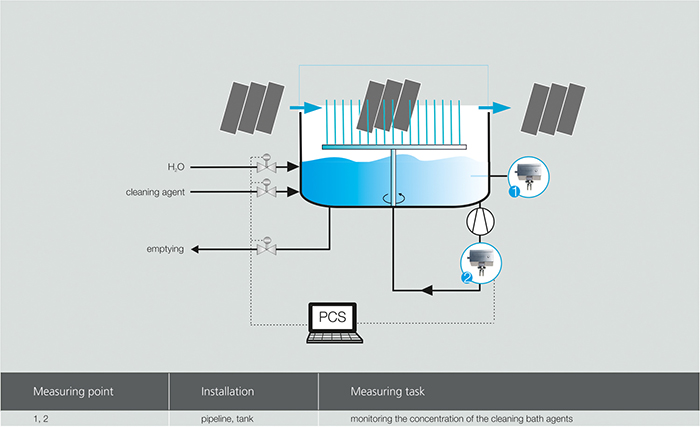

The cleaning process for PCBs includes a bath for dissolving contamination and one or more aqueous rinsing baths to remove the cleaning agent. Single-chamber, multi-chamber or continuous flow systems are used. The online measuring system is integrated into the cleaning plant in order to measure the concentration of the cleaning agent in both the cleaning bath and the rinsing bath. If the concentration decreases in the cleaning bath, the cleaning agent can be added immediately. In the PCB rinsing process, on the other hand, the concentration of cleaning agent in the bath increases. The measuring system indicates when the rinsing bath needs to be changed, thus avoiding carryover or too frequent bath changes. As an example, FIGURE 1 shows a spray cleaning bath with integrated measuring points.

Figure 1. To know how much fresh cleaning agent must to be added into the bath and to control bath changes efficiently a sensor is installed either in the pipe or in the bath.

Robert Bosch’s Automotive Electronics division develops, produces and sells microelectronic products for automotive and non-automotive applications. The product range extends from semiconductor components and electronic control units (ECUs) to non-automotive applications such as MEMS sensors for consumer electronics or eBike systems. Among the company’s products are electronic modules used especially for electric power steering systems in vehicles. As these are copper-coated high-end modules that carry high currents, Bosch places great emphasis on comprehensive quality management during the component production process. For that reason, the company’s production plants in Reutlingen, Germany, and Hatvan, Hungary, are equipped with special measuring systems.

Time-consuming discontinuous techniques such as titration have been replaced by the modern inline measurement technique that makes the measured data continuously available in real time and online. This increases process safety and minimizes the need for sampling and laboratory analyses with time-delayed results.

Titration not only involves time-consuming manual measurements, but also ongoing maintenance costs, since pH probes must be calibrated regularly. In turbid bath liquids, titration based on color change provides only inaccurate measurement results, so the real concentration of the cleaning agent remains unknown. Furthermore, titration requires use of additional chemicals, which neither saves resources nor costs. Novel sensor technology can measure in various bath liquids because the measurement method is independent of the turbidity and conductivity of the liquid and has a high tolerance of soiling.

The production lines at Bosch are in a clean-room and include, among other things, ultrasonic and spray cleaning baths. The integrated sensors measure the concentration of the aqueous cleaning agent inline and detect when the levels are above or below the limits, thus ensuring the concentration is always at an optimum with regard to performance and resources.

Concentration monitoring and continuous bath maintenance. The measuring points are used for monitoring the bath concentration and for continuous maintenance of the bath. Monitoring the concentration of the initial cleaning mixture, water is mixed with the concentrated cleaning agent in a container. The mixture is pumped through a pipe to the ultrasonic or spray cleaning bath. The circuit boards are cleaned in the bath, but carryover of the cleaning agent into the next bath and evaporation of the cleaning agent and water result in a change in concentration in the bath. To add the precise quantities of cleaning agent or water required, the concentration of cleaning agent in the bath liquid must be continuously monitored.

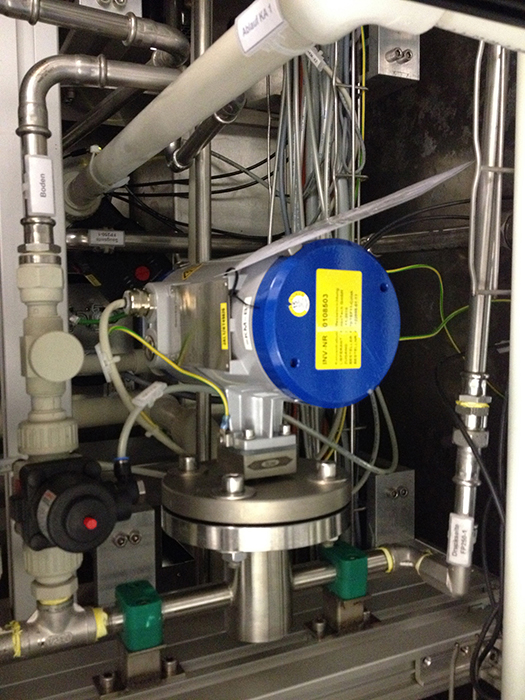

For this purpose, novel sensors were installed in an NPS ½" pipe in each cleaning system. Measurement requires neither a bypass nor stilling pipes. Standard DIN flanges were used to connect the sensor into the process. Alternatively, other versions such as Tri-Clamp or ANSI are also available for use according to customer specifications. FIGURE 2 shows a sensor installed in the circuit of an ultrasonic cleaning plant. The sensors carry out measurements in the concentration range between 20% and 40% by volume at process temperatures of between 70° and 140°F.

Figure 2. The immersion-type sensor is installed in a pipe of the cleaning plant at Bosch and continuously measures the concentration of the cleaning agent.

“It is important that we have precise and stable measured values,” said Dr. Jens Klein, process planner at Robert Bosch in Reutlingen. “The online measuring system helps us meet our cleanliness and quality requirements. By using continuous bath monitoring, we can ensure the correct cleaning of our products, and we also have an efficient use of cleaning agents, water and energy. That not only reduces our costs but also protects the environment.”

Inline measurement and online analysis. To measure the concentration, the sensor uses the principle of absolute sonic velocity measurement. This makes the sensors particularly robust, and they are able to provide stable values even in the presence of gas bubbles or in bath fluids that tend to form deposits. The measuring principle is based on runtime measurement, in which an ultrasonic sound signal is transmitted from one side of the sensor probe to the other. The distance and time are used to calculate the sound velocity. The ultrasonic signal is transmitted several times per second, which means the measured data are recorded and updated extremely quickly. As the sonic velocity depends not only on the concentration but also on the temperature, two Pt1000 temperature sensors are also integrated into the sensor. So the concentration is measured on the basis of the sonic velocity and the temperature. Measuring accuracy is 0.1 vol%. The correct operation of the sensors can be quickly checked by a system test in water.

Process overview. The mathematical model used for calculating the concentration is stored in the controller. The system is supplied as standard as a plug-and-play unit, which means the controller shows the current concentration on the display as soon as it is switched on. Clear trend displays provide a fast overview of the process. The measured data are stored in the memory of the controller, and at Bosch are transmitted to the PLC via 4 to 20mA signals. This enables the system to automatically add controlled quantities of cleaning agent and to indicate when the bath needs to be changed. Alternatively, the controller can be integrated into the process control system (PCS) via digital outputs, serial interfaces, Ethernet or a fieldbus such as Profibus DP.

The measured data that are stored can be read online via the process control system or via a PC. Software is used to analyze the data, to illustrate them in diagrams and to document them in logs.

“Another practical feature is remote-controlled communication between the units. Whenever we require support, we simply connect our controller to a modem,” said Dr. Klein.

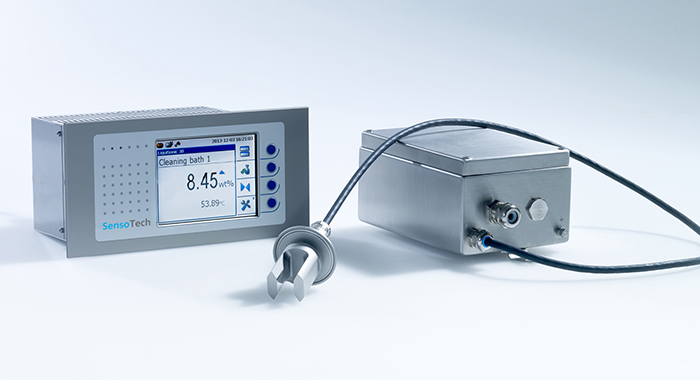

Measuring systems for different cleaning agents. The sensors at the Bosch plants in Reutlingen and Hatvan are made entirely of stainless steel DIN 1.4571 (equivalent to 316 Ti). For use in chemically aggressive bath solutions, corrosion-resistant sensor materials, such as Hastelloy or Tantal, or coatings of Halar or PFA, are also possible. A typical example of such an application is a pickling bath, in which Halar-coated sensors are used for measuring acid concentration. The cleaning agent used at Bosch belongs to the group of aqueous cleaners. As these do not have a flash point, the cleaning systems and the sensors do not have to comply with explosion-protection requirements. The opposite applies to anhydrous cleaning agents. For that reason, sensors with ATEX and IECEx certification, Zone 0 to 2, are available for use in potentially explosive atmospheres. The sensors can be easily integrated into any system. They are installed preferably in circulation pipes downstream of the pump or directly in the bath. The sensors can also be installed in small systems or pipes with small nominal dimensions, as flow adapters are available and the sensor electronics can be accommodated in a separate housing. FIGURE 3 shows a sensor with a separate electronics housing made of stainless steel and with IP 68 (NEMA 6P) level of protection. A controller can control up to four sensors. This results in lower costs in the case of several measuring points.

Figure 3. As an option, the sensor electronics are located in a separate stainless steel housing, thus allowing the sensor to be installed even if space is limited.

is marketing manager at SensoTech (sensotech.com); info@sensotech.com.

Press Releases

- PulseForge Makes Major Breakthrough Which Allows Flux-less Soldering in an Ambient Environment

- Panasonic Connect publishes case study on delivery of its surface mount technology (SMT) equipment to Dixon Technologies, one of India’s largest EMS companies

- CE3S and Desco Industries Announce May 2026 ANSI/ESD S20.20-2021 Certification Webinar Series

- Kurtz Ersa Goes Semiconductor: Expanding Competence in Microelectronics & Advanced Packaging