ROI of a Soldering Robot

When it comes to soldering, can a four-axis robot beat an experienced operator?

How does hand soldering compare to robotic soldering?

A Wisconsin-based OEM wanted to know, so it agreed to install a four-axis solder robot and run a production analysis against its most experienced hand soldering personnel. The analysis conducted by the OEM would be based on productivity, rework and return on investment over a three-week period using a solder robot.

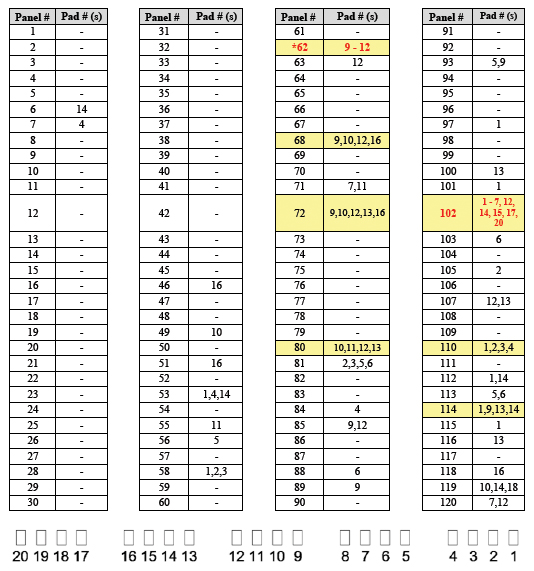

Test protocol. The OEM loaded two multi-up panels into a fixture, with each panel containing five boards. Each of the boards had four solder locations (joints), which totaled 20 solder locations per panel, or 40 locations per batch run. A SAC 305 solder with a 2% flux core was used for the test.

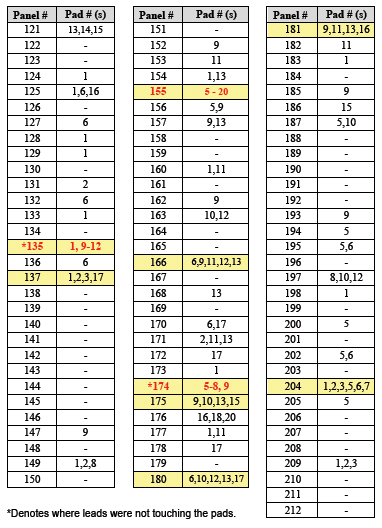

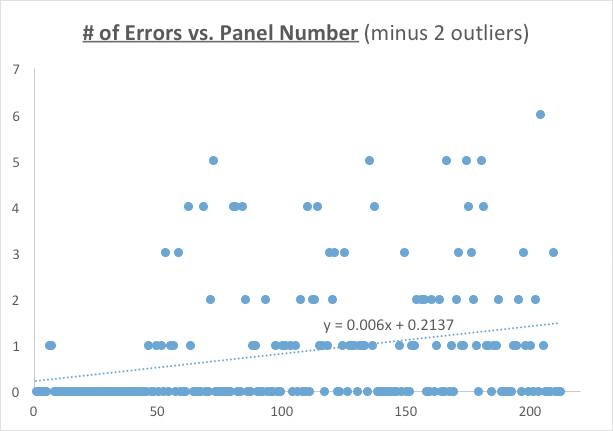

The test consisted of soldering a batch of 212 panels (4,240 solder locations, 1,050 PCBs) using a Quick 9434 series robot. The OEM compared defect rates of the solder robot with those of its current hand soldering process. The customer calculated the total time (with rework included) it took the robotic soldering process to yield acceptable products vs. the total time (with rework included) it took the hand soldering process to yield the same acceptable products. Data were input into an Excel spreadsheet by the OEM for final analysis.

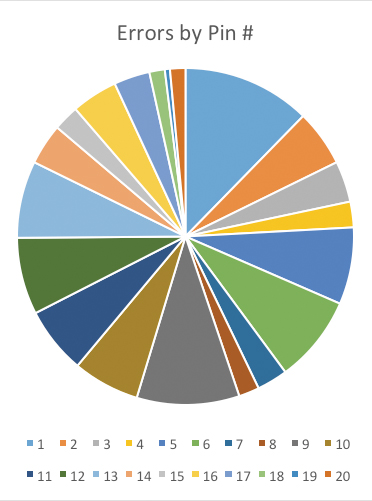

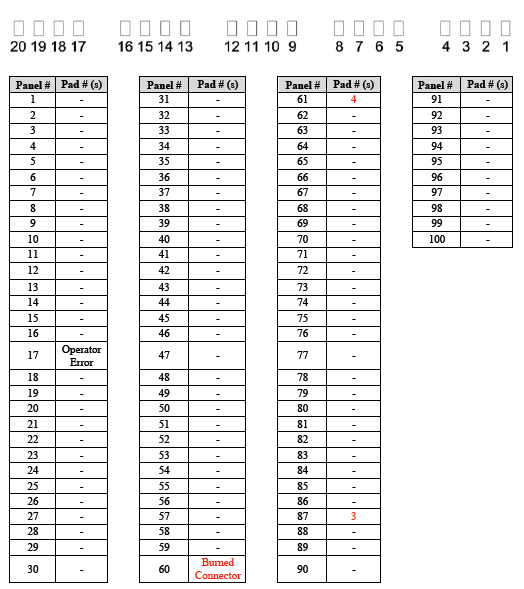

FIGURES 1 and 2 show the data. At the end of testing, the OEM found the solder robot had a 4.8% defect rate (203 errors) over the 4,240 solder locations. Excluding the five worst panels (161 errors), the failure rate was 3.9%. The hand soldering process did not have a measurable defect rate since joints were inspected and repaired by the operator who had originally soldered them, and touchup was conducted on the spot.

Figure 1. Solder robot data, first run, 2.5% flux (five-up panel / four joints each).

Figure 2. Solder robot data second run, 3.3% flux (five-up panel / four joints each).

Results. The results revealed the total time it took one operator to process 210 boards (with rework included) was 87.5 hr. The total time it took the robot to complete the same process (with human rework included at the 4.8% defect rate) was 44 hr. The overall time savings using the solder robot was 43.5 hr.

If production output were annualized (based on 2,080 hours per year/per employee), the hand solder operator would produce 23.7 batches (or 24,855 PCBs), and the robot would yield 47.2 batches (or 49,560 PCBs, rework included), a 49.7% productivity increase.

Other findings. The OEM was advised that use of a higher flux core solder wire (3% ~ 3.5%) could have permitted more consistent wetting of the solder when soldering with an automated robot. For testing, the customer opted to use a 2% flux cored solder it had on hand. Because a solder robot typically solders more joints in between cleaning cycles, a higher-flux-content solder wire is highly recommended, as it would help reduce the defect rate and extend tip life.

ROI was based on the solder robot’s purchase price vs. the cost of an operator (including benefits) based on the OEM’s location. While robot pricing varies based on the vendor and features, for the purposes of this analysis using the purchase price presented to the OEM, the robot demonstrated a 12.6 month ROI with one operator employed to load/unload, inspect and touch up the defects.

is president of Promation USA (promationusa.com); gary@promationusa.com.

Press Releases

- PulseForge Makes Major Breakthrough Which Allows Flux-less Soldering in an Ambient Environment

- Panasonic Connect publishes case study on delivery of its surface mount technology (SMT) equipment to Dixon Technologies, one of India’s largest EMS companies

- CE3S and Desco Industries Announce May 2026 ANSI/ESD S20.20-2021 Certification Webinar Series

- Kurtz Ersa Goes Semiconductor: Expanding Competence in Microelectronics & Advanced Packaging