Failure Analysis of PCBA Contamination

Step-by-step failure analysis guidelines assist in determining root causes.

Printed circuit board assembly (PCBA) contamination can impact an electronics manufacturing facility in many ways, with long-term product reliability being the major concern. This article details failure analysis guidelines, tools and examples to assist with failure analysis of PCBA contamination.

PCBA contamination is defined here as ionic contamination that may cause a reliability issue with the product. In general, ionic contamination requires a few catalysts to grow, including ions (in some cases chlorides), moisture and a power source.

The first step is to understand the makeup of the contamination. Many analytical tools exist to determine the ionic distribution within the sample. FIGURE 1 shows contamination detected in an assembly process. Given the many factors involved, each contamination issue should be analyzed case by case.

Figure 1. PCBA contamination.

For the example shown in Figure 1, ion chromatography would be a good starting point to determine the root cause. Depending on the location of the contamination, coupled with knowledge of the specific assembly process, additional analytical tools may be required to determine if organics or metals are present within the contamination sample. The overall key to using any analytical tool is the analysis of the results. Through the results of the analytical tools and by leveraging process knowledge, a hypothesis of the source of the contamination can be created.

Ion chromatography. Ion chromatography is a process that analyzes a sample to determine ionic contamination. With the analysis, the ion chromatography tool can detail specific anions present within a representative sample.1,2 The results of the analysis are displayed as a spectrum, which is plotted at time intervals and peak intensity of the ionic elements.

A standard is used to verify the ion chromatography system is working to the equipment specifications before an actual sample is measured and analyzed. One industry standard that may be used evaluates the sample for seven anions, including fluoride, chloride, phosphate, nitrite, bromide, nitrate and sulphate.3

Prepare the sample for analysis following IPC-TM-650 test method 2.3.28.3 Per the test method, small amounts of the PCBA contamination residue are dissolved in a solution (typically IPA and DI water), and then heated in an 80°C bath for 60 min. After one hour, the sample is ready to be inserted in the ion chromatography equipment for analysis.

Failure analysis. PCBA contamination can be detected throughout electronics manufacturing, including the assembly process, test and long-term testing stages, and finished goods. Understanding the root cause requires analysis of many inputs and variables of the manufacturing process and analytical testing results. Failure analysis of contamination involves collecting information, including component specifications, and an in-depth understanding of the specific assembly process. Using Figure 1 as an example, research would be required to determine the component specification and which assembly process (wave solder, solder pot or hand solder) was used to solder the through-hole component.

The first step is analysis of the contamination using the recommended ion chromatography process; the results will show the peak intensity of anions. This signature will be the foundation of the failure analysis to determine the root cause of the contamination. Subsequent steps include potentially analyzing components and PCBs to verify the incoming material is clean of ionic residue. After understanding the assembly process of the through-hole component, additional verification could include analysis of the manufacturing materials with ion chromatography (fluxes, solders, etc.).

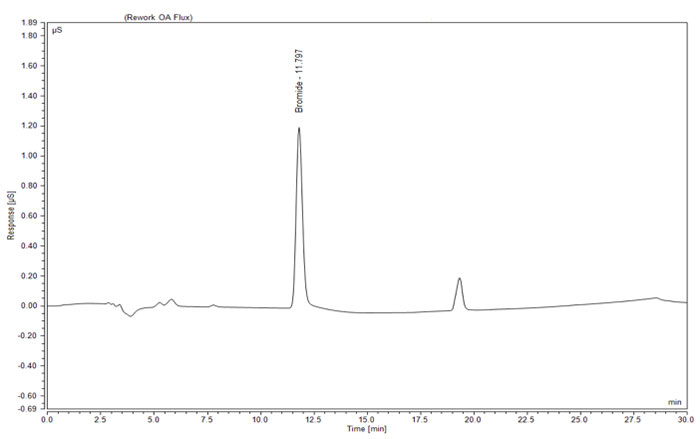

The final step is the determination whether any of the spectrums collected from the manufacturing materials or components match the original contamination results. Process and assembly knowledge will help with the root cause of why the contamination is present. FIGURE 2 details a manufacturing flux signature.

Knowledge of the spectrum signature of process manufacturing materials (solders, fluxes, etc.) can be used to determine potential sources of contamination or foreign matter. As an example, if the contamination spectrum matches the flux signature in Figure 2, additional investigation may be required to determine why the flux was not cleaned off the assembly properly.

Figure 2. Manufacturing OA flux spectrum signature.

The understanding of the entire assembly process is key to failure analysis because PCBA contamination can occur at various steps, including functional test and additive processes such as conformal coat. Conformal coat contamination can be a complex failure analysis, given the many variables involved with the overall cleaning, coating and curing process involved.

Cleanliness verification. Developing a process to verify ongoing assembly cleanliness will provide data to show whether the cleaning systems are within specification. Many cleaning analytical tools will normalize the results to provide a baseline. Ion chromatography can provide data results in micrograms per square inch (µg/sq./in.) to calculate the ionic density. This measurement uses the length and width of the assembly to normalize the area under each signature peak. Guidelines are provided within the electronics industry for PCBA cleanliness.4 Additional guidelines may be required dependent on product technology, lifecycle and operating environment.

Determining the cause of PCBA contamination can be challenging, given the many variables of assembly and test processes and the product lifecycle. Using step-by-step failure analysis guidelines will assist in the root cause. Ion chromatography is a useful analytical tool to assist in this process because of the specific signature generated by the tool. An electronics manufacturing facility can use failure analysis methods to determine the root cause of contamination and correct potential product reliability concerns.

References

- Scott Mazur, “Verifying PCBA Cleanliness with Ion Chromatography,” PCD&F/CIRCUITS ASSEMBLY, February 2017.

- Scott Mazur, “Verifying Electronic Component Cleanliness using Ion Chromatography,” IMAPS New England, 2017.

- IPC-TM-650, Test Methods Manual, method 2.3.28B, “Ionic Analysis of Circuit Boards, Ion Chromatography Method,” November 2012.

- J-STD-001F, “Requirements for Soldered Electrical and Electronic Assemblies,” July 2014.

is manufacturing staff engineer and environmental management representative, Benchmark Electronics, New Hampshire division (bench.com), and a contributing author to Green Electronics – Design and Manufacturing; scott.mazur@bench.com.

Press Releases

- Federal Electronics Expands Nearshore Capacity with Additional PCBA Line in Hermosillo

- Mexican Electronics Manufacturer Improves PCB Reliability with I.C.T Conformal Coating Line

- Cape EMS Unveils ‘CEB 2.0’ Roadmap to Drive High-Value Tech and Infrastructure Growth

- ECIA Calls for Tariff Stability as New Global Trade Framework Takes Effect