Benefits of an EMS for the EMS

Reuse of packaging and handling materials. In many cases, the best recycling approach is to reuse the item. This can be best accomplished with packaging and handling materials. Cases may surface in which the packaging material is not recyclable; this may result in a redesign to recyclable material or reusable packaging. Upfront design will be needed for this determination, ideally before product introduction.

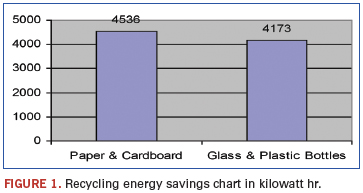

Figure 1 can be used to calculate energy savings for the recycling activities at the EMS facility. The metric is calculated on the assumption that recycling saves energy verses the total manufacturing process of creating new material. In the example below, the kilowatt per hour (KWH) savings was based on one ton of paper, cardboard, glass and plastic bottles recycled.

The combined total energy saved is equal to approximately the average household energy use for one full year. Calculators are available through state and federal (EPA) environmental departments and websites.

Other opportunities for projects include energy reduction through lighting and motor improvements and chemical, waste and material reductions. In most cases, energy objectives can result in a cost reduction, usually by modifying lighting times and upgrading lighting fixtures and motors to energy-efficient equivalents. It is important to understand the simple payback of the project; on occasion, rebates are available that can be factored into the calculation.

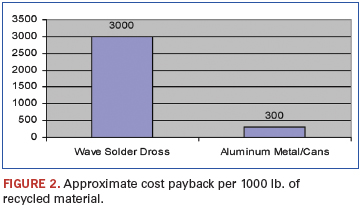

Potential cost and environmental payback. In addition to the benefits of completing environmental objectives and pollution prevention, cost reductions and paybacks can be potentially received. Electronics recycling, given the current market of metal pricing, provides a cost payback for scrap metal, subassemblies and wave solder dross. Figure 2 details an approximate cost payback per 1000 lb. of wave solder dross, aluminum cans and metal.

The biggest payback would be from the wave solder dross, which will be refined by the recycling supplier and associated metals (tin, copper, silver, etc.) extracted. Depending on market conditions, cardboard and paper recycling may also provide a payback. Some recycling activities will not result in a cost payback; the result will be the environmental benefit of the material not being discarded in a landfill.

Conclusion

The actions above can all benefit the environment. Moreover, EPA and state recognition and awards are available to successful companies. Employee involvement is important to any recycling program, given their knowledge of the process and products. Employees also have impacts on energy reduction, waste disposal and handling. A material or item that has been historically thrown away may be recycled or reused; employee involvement will bring attention to these new opportunities.

By setting up an environmental management system, a facility can monitor and comply with regulatory requirements and set up a program for environmental objectives and projects. In some cases, the results of the environmental project can provide a cost reduction or cost payback. By training and involving employees, many recycling ideas will surface to the benefit of the environment and manufacturing facility.

Scott Mazur is a manufacturing staff engineer and environmental management representative for Benchmark Electronics (bench.com); scott.mazur@bench.com.

References

1. Scott Mazur, “Environmental Recycling for the EMS” – SMT, October 2010.

2. Scott Mazur, “Developing an Environmental Management System for the Electronics Manufacturer,” IMAPS New England Symposium, May 2011.

- << Prev

- Next

Press Releases

- Altus Reports Growing Demand for Guidance on Convection Reflow Oven Specification

- Coherix Opens New Adhesive-Dispensing Vision Center in Europe

- Pan Pacific Strategic Electronics Symposium Program Finalized

- The Most Critical 2 Inches in SMT Manufacturing – When a Splice Fails, the Line Fails, Full Stop. Throughput and Yield Depend on One Overlooked Moment