Damaged Through-Hole Plating

Microsectioning shouldn’t be taken lightly, lest the sample be damaged.

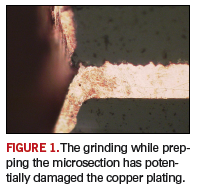

The microsection image shows an open connection between the through-hole copper plating and the innerlayer tracking. The microsection has been poorly prepared, with potential damage to the plating during grinding. As shown, no resin is in the hole to support the through-hole copper plating. The surface of the copper is rounded, making it impossible to prove the root cause of the problem in this example.

It is accepted that the sample has been poorly prepared. Any time a section is being prepared, it is important resin enters the through-hole. In the case of via holes, they may be coated with solder mask; in this case, the mask surface must be broken to permit resin to enter the hole. If a section is found to not have resin in it prior to grinding to the center, it’s important to stop grinding. This permits the hole to be filled with resin, recurred prior to further grinding of the sample.

These are typical defects shown in the National Physical Laboratory’s interactive assembly and soldering defects database. The database (http://defectsdatabase.npl.co.uk), available to all Circuits Assembly readers, allows engineers to search and view countless defects and solutions, or to submit defects online.

Dr. Davide Di Maio is with the National Physical Laboratory Industry and Innovation division (npl.co.uk); defectsdatabase@npl.co.uk.