Bridging Causes, Part 3

Identify and solve placement and reflow-related solder defects.

We continue our series on solder bridging. This month, we look at potential problems caused by the placement machine and reflow profile.

If the pick-and-place machine is suspected:

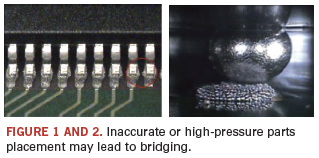

Problem: Placement inaccuracy narrows gap between pads, increasing the chance of bridging.

Recommendations:

- Verify component placement pressure.

- Use x-ray to verify BGA placement.

- Use microscope for QFPs.

Problem: Excessive component placement pressure will squeeze paste out of pads.

Recommendations:

- Verify actual component height against data entered in the machine.

- Component placement height should be ±1/3 of paste height.

If the reflow profile is suspected:

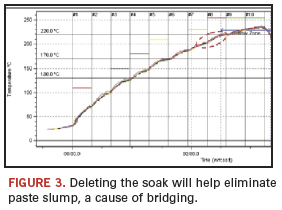

Problem: Extended soak will input more heat to the paste and result in paste hot slump phenomenon.

Recommendation: Adopt a straight ramp to spike profile, without soak zone if possible.

Paul Lotosky is global director - customer technical support at Cookson Electronics

(cooksonelectronics.com); plotosky@cooksonelectronics.com. His column appears monthly.