Insufficient Fill

Published: 07 January 2011

by Paul Lotosky

What to do when solder isn’t penetrating the aperture.

Insufficient fill occurs when the amount of solder paste deposited on a printed circuit board by the printer is much less than the stencil opening design.

Among the potential causes:

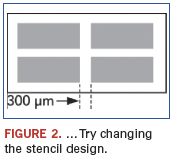

Stencil: Paste scooping effect, especially on large pads.

Recommendation: Segment the large opening into smaller apertures.

Screen printer: Paste does not roll into aperture.

Recommendations:

- Reduce print speed.

- Increase print pressure.

- Adopt lower squeegee contact print.

- Ensure paste is not expired or dry.

- Ensure sufficient board support.

- Reduce squeegee pressure.

Paul Lotosky is global director – customer technical support at Cookson Electronics (cooksonelectronics.com); plotosky@cooksonelectronics.com. His column appears monthly.

Press Releases

- PulseForge Makes Major Breakthrough Which Allows Flux-less Soldering in an Ambient Environment

- Panasonic Connect publishes case study on delivery of its surface mount technology (SMT) equipment to Dixon Technologies, one of India’s largest EMS companies

- CE3S and Desco Industries Announce May 2026 ANSI/ESD S20.20-2021 Certification Webinar Series

- Kurtz Ersa Goes Semiconductor: Expanding Competence in Microelectronics & Advanced Packaging