Flux, Reflow Ovens, NASCAR and Moonshine

The connection between flux and reflow ovens is obvious, but are there ties to stills and race cars too?

When my wife and I moved to Raleigh, NC, we soon realized we landed in the center of the universe for NASCAR fans. Richard Petty, Richard Childress, Dale Earnhardt, Junior Johnson, Dale Jarrett, Austin Dillon, J.D. McDuffee, Bobby Isaac and Rick Hendrick are a few of the well-known figures from NC. NASCAR race shops are all over the state. Towns such as Level Cross, Welcome, Kannapolis, Charlotte, Mooresville, Concord and Randleman are on every fan’s destination bucket list. Racetracks such as Bowman Gray, Charlotte, Rockingham, Ashville, Caraway, Fayetteville, North Wilkesboro, Orange County, Hickory, South Boston (VA), etc. are within a couple hours’ drive of our NC home.1

The roots of NASCAR are deeply embedded in bootlegging, where souped-up, high-performance cars were used to transport illegal liquor. Although prohibition ended in 1933, production of illegal whisky continued for years, as bootleggers sought to avoid taxes and sustain their families. Someone once said that the first automobile race came about when the second car was built and the bootleggers soon began racing to prove their modified car was the best. This backwoods racing went on for years in farm fields and independent tracks until Bill France Sr. organized many of them into NASCAR in 1948.2

Figure 1. View of the start of a NASCAR race from the pits at New Hampshire International Speedway.

So, how do we get from moonshine and NASCAR to solder reflow?

We need to look closely at North Carolina to get an answer. North Carolina is known as the Tar Heel State because of pine tar, the basis of rosins and resins used in many fluxes. It started with the abundance of pine trees that were in the area when Europeans first began settling North America. In the May 2015 issue of HOMES & GARDEN, Andrew Kenney explains how the Tar Heel name came about:

Lawrence Earley writes in Looking for Longleaf, “In 1584, that two captains told Sir Walter Raleigh that these ‘trees could supply the English Navy with enough tar and pitch to make our Queen the ruler of the seas.’ The seamen were referring to pine tar – the viscous fluid that leaks from heated pine, used to secure masts and sails, and used on boat bottoms for waterproofing. These products helped to foster a backwoods industry – and turned NC into the home of the Tar Heels. The nickname stuck, as one tale has it, when the gluey stuff met poor workers’ bare feet in farms and distilleries.

According to Timothy Prizer’s 2009 thesis “Pining for Turpentine,” North Carolina accounted for up to 96 percent of the nation’s “naval stores,” relying heavily on slave laborers throughout the 1800s. The longleaf trees also yielded the sturdy beams that braced mills and warehouses, some of which still stand today.

Being from New England, I thought that Maine was the Pine Tree State. A bit of research revealed that while at one time Maine had an abundance of pine trees, they slowly disappeared as the first colonists used the wood to build homes and ships, and the pine pitch – the glue processed from pine tar – for candles and sealing ships. By the 1800s, the vast supply of Maine trees had diminished, and production of pine tar switched to the Carolinas. There, the longleaf trees (southern pine), whose needles approach 18″ long, are slightly different than the shorter needle New England white pines (FIGURE 2).

Figure 2. North Carolina longleaf pines.

When one looks closely at pine trees, they see that the pitch is usually translucent and amber in color with some white crystals, just like the residue we see in dirty reflow ovens. In fact, a major component of solder paste is rosins and resins that are combined with solvents to make the flux. These rosins and resins are generally made up of derivatives of pine pitch.

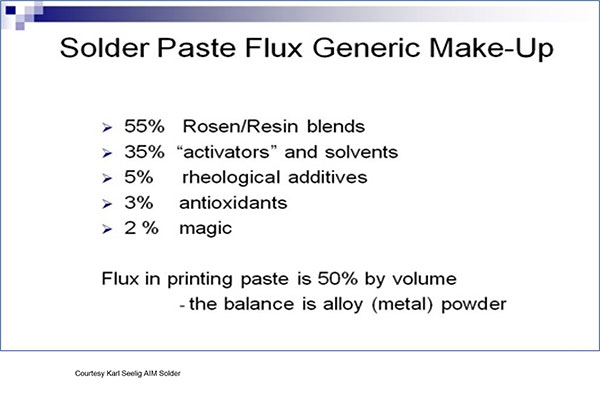

According to Karl Seelig of AIM, solder paste is about 50% flux and 50% metal by volume, with about half the flux composed of resins and rosins (FIGURE 3). Seelig also reports that about 50% of the flux remains on the board after reflow and that 50% is mostly the resin and rosins. Therefore, most of the components of flux that enter the oven atmosphere during reflow are the activators/solvents and AIM’s other magic additives.

Figure 3. Composition of flux. (Courtesy Karl Seelig)

Condensation Principles

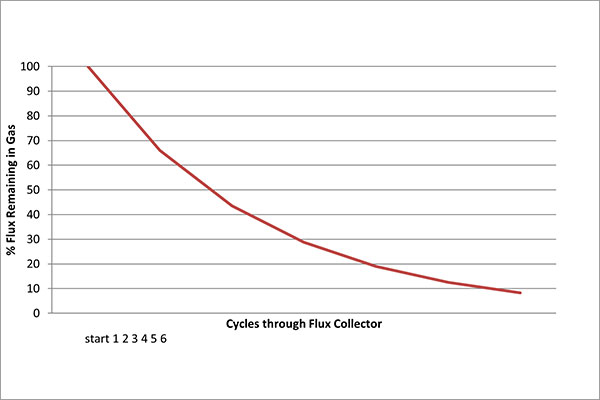

Moonshine stills work on the same principle of condensation as most flux collection systems. The solvents and many of the additives have a low vapor pressure and enter the oven atmosphere in the early parts of the thermal cycle (the first few zones). This flux-laden nitrogen is then moved to the collection system, cooled and filtered, and the “somewhat” clean nitrogen is returned to the oven. The nitrogen is called “somewhat clean” because condensation systems are usually about 30% efficient. This means that about two-thirds of the flux is returned to the oven with the gas (FIGURE 4), and must be cycled through the collection system numerous times to attain desirable levels. This is why some high-volume reflow ovens have dual heat exchangers and some high-volume manufacturers have dual flux collections systems.

Figure 4. Percent of flux remaining in the gas after cycling through the flux collector.

The goal of a moonshine still is to separate the product (condensate) from the heated gas and put it in bottles for distribution, while the goal of a flux collection system is to clean the gas for reuse. The sticky condensate is discarded. Although the goals are different, the condensation technology is the same. But the residue in a flux collection system adds a burden to the system because the condensate clogs the heat exchangers and filters instead of flowing into jugs like moonshine. This sticky stuff needs to be removed from the system; otherwise, its efficiency is degraded and it removes less than 30% of the flux during each pass. In many cases this maintenance or cleaning requires hours of oven downtime each week (depending on the production rate) and the byproducts of cleaning are difficult to dispose of. (No moonshiner would run a still that took hours to clean.)

Until recently, reflow oven manufacturers had little choice in the design of flux collection systems due to cost, cooling efficiency, filters and space limitations. Collection systems based on burning the flux are available (pyrolysis), but are cumbersome and expensive to operate. But like NASCAR innovation, oven OEM engineers have found a way to increase flux collection efficiency, significantly decrease maintenance time, and make it easy to dispose of the cleaning byproducts. This system is based on wet gas scrubber technology like that used to clean ash from the exhaust of coal plants. In these systems, the polluted gas stream (nitrogen-containing flux particles) is brought into contact with a liquid which traps the particles. Then the clean gas exits the collection system and returns to the oven. The liquid may also lower the temperature of the gas, thus attaining higher collection efficiencies. To the joy of the maintenance staff, once the cleaning liquid becomes dirty, it can easily be replaced and disposed of.

Detailed explanations of the gas wash system are available in the following papers:

Paul Richter, “High-Efficiency, Low-Maintenance Flux Removal Method for Reflow Ovens,” SMTAI Proceedings, 2020.

Fred Dimock, “Flux and Flux Management in a Nitrogen Reflow Oven,” SMTAI Proceedings, 2020.

Richter concludes that flux collection efficiencies approaching 90% have been achieved with the gas wash system, and operating expenses – including depreciation – are significantly less.

Therefore, flux, reflow ovens, NASCAR and moonshine are connected through distillation, condensation and innovation. Best of all, like the NASCAR pit stops, the efficiency and maintenance of the flux collection systems has been made easy and fast (FIGURE 5).

Figure 5. SMT reflow oven maintenance might not be as fast as the 15-sec. NASCAR pit stop, but it can improve with available technology.

Notes

1. Bowman Gray, in Winston-Salem, NC, has been running weekly races in a “football stadium” (yes, football stadium) for close to 75 years and is nicknamed “The Madhouse” for excellent reasons. The racing is insane, the stands are packed, and adult admission is less than $15.

2. In the 1950s illegal shine was produced in northern Wake County, just outside Raleigh. The moonshine stills were legalized in the early 1970s when the gas shortage generated a need for stills to produce gasohol. These stills were operated until 1976 when Raleigh’s municipal expansion got in the way.

is semiretired and principal of Fred C Dimock Global Services (fcd-global.com). He has more than 40 years’ experience in high-temperature soldering and sintering, including more than 20 in SMT reflow soldering; fred@fcd-global.com.

Press Releases

- Smartsol and Koh Young Technology Announce Strategic Partnership for the Mexican Market

- RBB Systems Boosts Manufacturing Capabilities with Equipment Upgrades for 2026

- 11th Class of Engineering Interns Begins Forging Success at Hyrel

- Rocka Solutions Announces 2026 Rockin’ Roundtable: An Interactive Discussion on What Really Drives SMT Printing Performance