Root Causes of Component Lifting

Soldering in nitrogen or vapor phase environments can increase the likelihood.

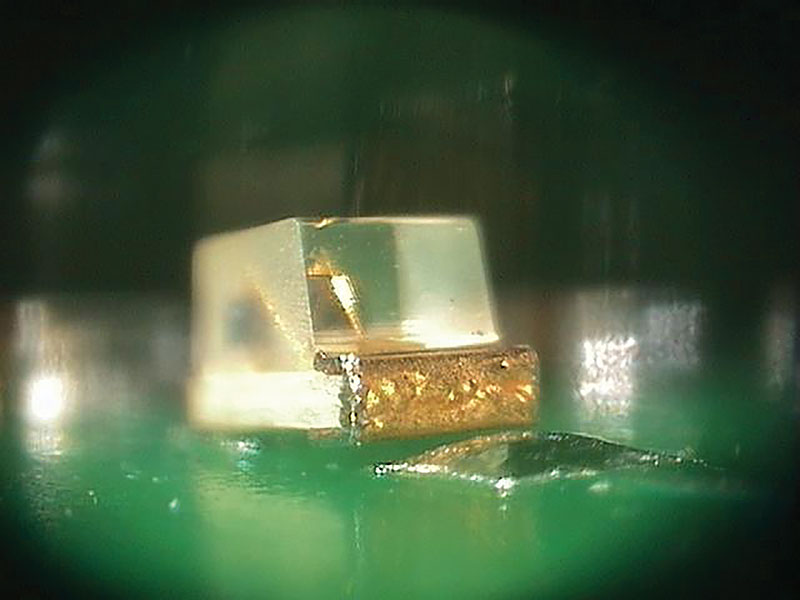

Subtle component lifting can be an issue to find during inspection. Most modern AOI systems should be able to detect drawbridging on small passive and active parts. Old systems may struggle with defects like the two shown in FIGURE 1.

Figure 1. Passive parts printed with excessive solder or on incorrect pads are more susceptible to lift.

There are many papers on lifting of parts during reflow and many suggestions on the root causes. In our experience, the most common reasons are excess solder paste, an excessively thick stencil, or poor pad design. These issues are exaggerated by fast wetting, as seen in nitrogen and vapor phase soldering. To be clear, nitrogen or vapor phase do not cause lifting; they just increase the possibility of component lift.

We have presented live process defect clinics at exhibitions all over the world. Many of our Defect of the Month videos are available online at youtube.com/user/mrbobwillis.

is a process engineering consultant; bob@bobwillis.co.uk. His column appears monthly.

Press Releases

- Kurtz Ersa Goes Semiconductor: Expanding Competence in Microelectronics & Advanced Packaging

- ECIA’s February and Q1 Industry Pulse Surveys Show Positive Sales Confidence Dominating Every Sector of the Electronic Components Industry

- Hon Hai Technology Group (Foxconn) Commits To New 5-Year Sustainability Roadmap Through 2030

- Amtech Electrocircuits Navigates Supreme Court Tariff Ruling