Current Issue

IPC-1782: The New Dawn of Electronics Traceability

One standard to rule them all.

There has never been a standard for traceability in the electronics assembly industry. Crazy, right? Instead, traceability is thought of as expensive, complex, unreliable, incomplete, a threat to business and different for everyone. Sadly, all these observations have been historically true. After an epidemic quality issue with memory chips, and with growing incidences of counterfeit materials entering the supply chain, the IPC-1782 Task Group was created. And the task group has now completed the first all-encompassing traceability standard for electronics, which is designed to be applicable to every product, in every company, addressing all the issues listed above.

In electronics assembly, a bill of materials (BoM) can have thousands of components for a single product, which may consist of several subassemblies, key components such as a battery, storage, screen, etc., as well as bespoke and common raw materials. The average product will have been assembled using many different types of automated machine processes, from many different vendors, all doing different kinds of work. Then, many manual processes are required to complete the PCBs, including final product assembly, complex testing, customization, and preparation for shipment.

Actually, average product cost is hard to gauge, as electronics vary from cheap, simple devices, such as a USB stick, to complex, safety-critical product, such as the latest smartphone handset, a nuclear power-station controller, autonomous driving processor, satellite module, or missile guidance system.

Knowledge of how the product was made, the materials used and the processes performed has become increasingly critical. Traceability and manufacturing management compliance have become closely associated. Traceability requirements are typically called out by OEMs in contracts as part of the manufacturing compliance requirement. The fact that data recording is performed shows the process is being managed, that critical checks are being made. The value of traceability in the first instance is to help ensure the product is made correctly, including transactional events such as the material verification process. Process-flow recording ensures the product visited each process in the correct sequence and passed any tests at those points.

Data collected in this way have value, the benefit of which depends on the data accuracy and level of detail. Should a product be found defective, action can be taken beyond the simple “fix and forget” approach. The first detection of a defect can lead to the understanding of a potential “epidemic” problem, which may affect, or has already affected, thousands of products. In a worst-case scenario, an epidemic defect could cause a safety issue that could lead to the recall of tens or even hundreds of thousands of products.

If, on the other hand, the issue can be identified using traceability related to a specific scope of materials, which for example had been found to be counterfeit, then a “precision recall” can be made where only the exact product units shipped are identified and recalled, in a far more cost-effective, less public and well-managed way. This can be extremely important where customer confidence is concerned with safety critical and branded products.

As well as the avoidance of recall cost, traceability data can be used internally within manufacturing to identify patterns and trends of issues, and it can even help resolve the most difficult “one-off” defects. For example, if a thousand products have been made, and just one is found with a defect, then there must have been a unique set of circumstances that caused that defect, even though in principle all processes and materials should have been the same. By looking through detailed traceability records with advanced analytics, the unique combination of factors most likely to have led to that defect occurring can be found.

For some defects, usually found during extended test or in the market, the production processes were perfect, yet failures still occurred. If proof exists the product was manufactured with the right materials and went through the correct processes with the correct setup, then a design-related issue may need to be resolved.

For the first time, detailed traceability data can, clearly and without doubt, provide feedback to the design process to modify design for assembly (DfA) rules so quality and reliability improvements can be made. This provides a strong degree of assurance that, for these issues, the customer will not incorrectly hold the manufacturer accountable or responsible. In this respect, traceability data are like insurance for the manufacturer.

In summary, the value of traceability is to reduce the effects of catastrophic product issues that require recall, enable a far higher degree of quality management, and attribute responsibility for defects accurately. These values favor the manufacturer and product owner, an essential factor for the success of traceability, so it yields a benefit to the manufacturing operation rather than being a burden.

The History of Traceability

Use of computers in electronics assembly manufacturing, other than built-in process controllers, is limited. Collecting data from key points in the processes started manually with the recording of serial numbers and process information on paper. This created the sense of traceability as a burden right from the start, because information collected was only detailed enough to be used in the case of a catastrophic issue to help identify the needed scope of a recall. Although they happen, no one actually plans to have such catastrophic issues, and so the data collected are often regarded as overhead. Storage of such information was also a challenge, with what seemed like warehouses continuously being filled with paper records. Computer databases were slow to be adopted, as computer technology was in its infancy, with formats and methods changing year by year and making older data records incomprehensible. The reliability was not there until quite recently, relatively speaking.

Over time, more data were required as the need for compliance and quality assurance grew. The will to move toward a “zero defect” operation created additional costs for the operation for traceability data collection. Manufacturing companies were keen to keep costs under control and wanted to record only what was necessary. Business owners, however, pushed for more data, in the sense they were mandating higher degrees of operational compliance. Thus, the specification of traceability became a key part of the manufacturing contract.

Different companies in key areas of the industry, such as automotive OEMs, created their own set of high-level rules for traceability data that should be collected as part of conformance practices. This was also adopted by military and aerospace applications. Eventually, even higher level consumer companies, such as Apple, have become famous in the industry for their conformance/traceability requirements because loss of brand confidence over simple quality or reliability issues can have a huge effect on their business.

The problem is that with all of the different specifications, and without an in-depth understanding of the processes themselves, the actual requirement of exactly what data should be recorded, from where, and how it was supposed to relate to the product and process, was left undefined, allowing them to be interpreted on a case-by-case basis. This has meant that, in many cases, perhaps even most cases, the traceability data needed are not reliable or complete, and/or irrelevant data are also being collected. Negotiation of traceability requirements between the product owner and manufacturing has become increasingly difficult because neither is speaking the same language, and there is no point of reference. The result has been continued spectacular and public cases of product recalls, while electronics systems are becoming a more critical part of everyday life, and elements such as counterfeiters become more common and significant.

A New Standard

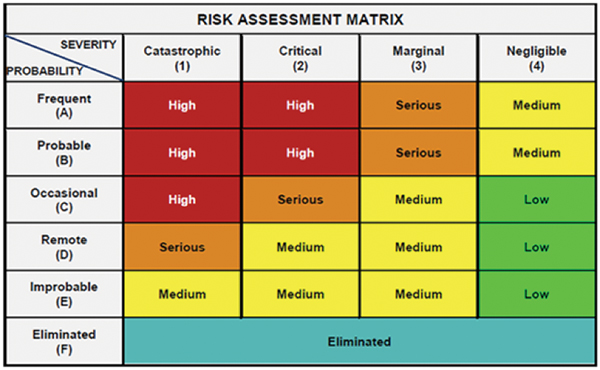

With recognition of all these issues related to traceability, the IPC-1782 Task Group created a traceability specification applicable to all electronics assembly, extending to all assembly and mechanical operations that feature as part of electronic products. The key focus, however, was on electronics assembly itself. The starting point was the assessment of risk, mapping the degree of severity and probability of a defect to the impact that an issue may have on the business. FIGURE 1 from MIL-STD-882 is a good example of such a risk assessment matrix.

Figure 1. Example risk assessment matrix (from MIL-STD-882).

It is clear extreme levels of traceability data collection, whereby every scrap of data is gathered from every possible process, were going to be too much for the vast majority of the industry. The level of data collection should be assessed against the risk associated with potential defects occurring in the product.

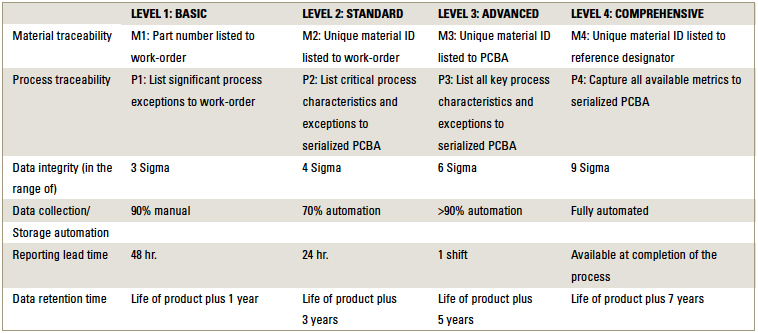

At the same time, the IPC product classification system was used to guide the need for different levels of traceability data collection. As a result, IPC-1782 defines four levels of data collection, each for material data and process-related data, summarized in TABLE 1.

Table 1. IPC-1782 Summary of Traceability Levels

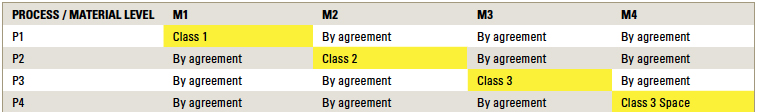

Roughly, the “Low,” Medium,” “Serious” and “High” from the risk assessment matrix equate to the four levels of traceability as defined in IPC-1782. The IPC product

classification system of “Class 1,” “Class 2,” “Class 3” and “Class 3 Space” equate in the same way.

In each case, however, especially as IPC-1782 is introduced, there will be variations depending on the history and nature of the product, and the market into which it is sold, so these mappings are provided as guidelines. The level of material traceability and process traceability often can be different, with additional exceptions defined and agreed between the product owner and the manufacturer. Once the determination of the level is made and agreed, however, the specification of what are the appropriate and expected traceability data is clear.

As well as the level of detail, the levels of traceability also define key factors of performance for the collection and use of the data, which include data integrity, degree of data collection automation and retention time. The greater the degree of automation of data collection, either directly from machines or as part of transactional control systems of manufacturing, the more accurate and timely the availability of the data, and hence its usefulness.

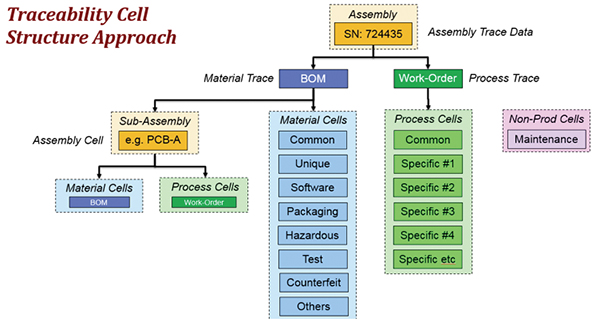

Overview. The nature of electronics assembly is hierarchical. A finished product, represented by an assembly cell, is typically made up of raw materials plus subassemblies. Each subassembly is, in turn, a finished product of another assembly process also made up of raw materials and potentially other subassemblies. It made sense, then, to the IPC-1782 Task Group that the structure of traceability data should align with this physical reality. FIGURE 2 is a simple illustration of this structure.

Figure 2. Illustration of hierarchical data structure approach.

The assembly cell, identified as “724435” in this example, contain data about such things as the work-order and process sequence, BoM, and the process traceability data, which are a record of events and transactions that have taken place during the assembly process, and the materials traceability data, which contains information about specific raw materials, as well as other “roots” of information about each subassembly.

A raw material is differentiated from a subassembly as any component that does not in itself have a traceability record. Because this approach is quite modular, the traceability detail of subassemblies can be combined easily at a later date, either when the subassembly is used, or even later, provided the unique ID of the subassembly is recorded. The subassembly data can later be imported or simply referred to when stored in a connected system.

For each of the materials and processes, specific cells of information then are defined that contain different attributes. IPC-1782 lists requirements for data capture for each of these cells as is relevant according to the specific level of traceability chosen, M1 through M4, and P1 through P4. In the case of process traceability, common elements of traceability data apply to all processes and then additional requirements that are dependent on the specific process type. Common elements are, for example, process name or ID, time in and out of each PCB, etc. Specific data by machine type would include, for example, the list of materials consumed for an SMT process, as well as details of machine errors during the operation, whereas a test process would include a pass and fail result, as well as process measurement data.

For all the materials identified as being used at each process, the associated material traceability data cells are referenced. Information in these cells can include unique material IDs (as well as unique carrier IDs), supplier, date code, etc. The method of linking material traceability data through the use of unique IDs and the cellular structure of the data means that, at higher levels of traceability, data do not need to be repeated within the data structure. Any specific material, identified by an ID with associated traceability data, is needed only once and may be referred to from many reference designator positions on many different assemblies, and even across many different products. This helps reduce the storage requirement for the data by a significant amount by eliminating needless duplicate data.

In addition to product-specific records, the traceability structure also includes data relating to equipment maintenance, kept separate from the assembly tree structure, because it need not be related to any specific product, but is time-based data that may occur while a product is being made or between products.

Implementation. Both in concept and in practice, IPC-1782 is designed to be as simple as possible to understand and execute. The standard could not be just a simple linear list of requirements. Given the hierarchical nature of the data, understanding the content of different cells with the different levels of detail is a requirement to getting started. The specification of the standard will be supported by information and examples of how it can be applied and used, as well as exactly what the data fields represent.

The recommendation for getting started is to use the risk assessment methodology and IPC classifications to determine the target levels for traceability. Level 1 traceability for either process or materials is really the minimum level that would be expected for any manufacturer of good standing. Level 4 would likely be appropriate only for the highest demands in the industry, especially where process data are concerned. In the case of EMS companies, different levels of traceability may be required for different lines of products or for different customers.

The next step in adoption is to compare the calculated requirement with what is currently in place, represented by existing quality or management control systems, or as negotiated with customers or product owners. Most data required for traceability are likely to exist within the operation, making it a matter of establishing a communication method for the data to be brought together in the form that IPC-1782 requires. Avoiding manual data collection will decrease the cost of traceability implementation and also increase the accuracy and timeliness of the data collected.

Most automated machines in the market going back many years have some sort of data availability, which may require machine-vendor software support. Data may also be collected from transactional systems such as planning, material control, and including verification operations, etc. All these sources of data can be combined more easily through the adoption of a single format, such as the Open Manufacturing Language (OML), available today, which already supports IPC-1782 requirements. A single common language ensures a minimum of integration effort into databases, including cloud systems, as well as “Smart” computerizations related to Industry 4.0 and Smart factories.

Negotiation of contracts and agreements between manufacturing and product owners is next, using the much more simple definitions of expectation. Some education about the implementation of the standard, including how data are collected, may be required in the earliest stages. The selection of the levels of traceability, related to materials and process, may initially start at a lower level until the inter-process communication infrastructure can be established and reliable in practical operation. The levels may then be increased over time, as increased values from the traceability data are sought and related costs of data acquisition diminish, for example, as machine vendors adopt communication standards directly.

Expected results. Unlike management-driven requirements that include a degree of traceability, positive results from use of IPC-1782 can be significant and immediate, such as:

- Streamlined negotiation: Because it is relatively easy to determine the required level of traceability between product owner and the manufacturer, with content of the requirement clearly defined for each level of traceability, risk of misunderstanding is reduced, as is the complexity of negotiation, reducing lead-times for contracts.

- Reduced costs of data collection: With clarity over exactly what needs to be collected, and what is not needed, the overall cost and impact of traceability can be minimized, while at the same time, assurance is made that the traceability data meets expectation.

- Effective auditing: As the trust between manufacturer and product owner increases, audits can be far less painful because both parties know exactly what to expect and what is required.

- Reduced recall costs: Because the content and quality of the data meet expectation, any serious issues that do occur can have the scope of remedial activity identified to minimize recall and rework costs to a minimum, as well as protect brand reputation and customer satisfaction.

- Reduced cost of poor quality: Internally within the manufacturing operation, exceptions and deviations can be quickly understood through the use of traceability data to improve both internal and market quality far beyond traditional quality-management techniques. Responsibility of issues can also be quickly and accurately attributed to production, materials or even design, creating the environment for real and continuous improvement.

- Accountability for counterfeit materials: One of the most shocking trends in manufacturing is the rise in the incidence of counterfeit materials, not only of key components such as ICs, batteries, etc., but of regular passive components. Use of any of these counterfeit materials can cause serious quality and reliability issues in the market. The detection of counterfeit materials is potentially an expensive burden on manufacturing, and it only acts as a filter, not a real deterrent against counterfeiters entering the market. This epidemic will continue to grow until a clear line of unambiguous accountability back to the originator of the counterfeit ingress can be established.

IPC-1782 will quickly become a critical part of electronics assembly manufacturing and is expected to expand into related industries in due course. With potential integration of technologies for component marking and open manufacturing communication standards, traceability becomes part of the optimized factory operation and provides the benefits without being a net burden. IPC-1782 has been created to bring an end to the confusion and ineffectiveness of complex, yet vague, traceability requirements within management conformance mandates, and it enables factories to get much closer to the ultimate goal of zero defects throughout the entire manufacturing and supply chain.

Table 2. Indication of Levels of Traceability vs. IPC Product Classification

is marketing development manager, Mentor Graphics (mentor.com); michael_ford@mentor.com.

Press Releases

- PulseForge Makes Major Breakthrough Which Allows Flux-less Soldering in an Ambient Environment

- Panasonic Connect publishes case study on delivery of its surface mount technology (SMT) equipment to Dixon Technologies, one of India’s largest EMS companies

- CE3S and Desco Industries Announce May 2026 ANSI/ESD S20.20-2021 Certification Webinar Series

- Kurtz Ersa Goes Semiconductor: Expanding Competence in Microelectronics & Advanced Packaging