2005 Articles

Fluxing: The Critical Parameter in Wave Soldering

Fluxing is a critical parameter in the wave soldering process, and with the introduction of Pb-free soldering, flux can determine whether the process is sucessful. There is more to consider than just the choice of fluxes; success also depends on how the flux is applied, and the accuracy of that application method.

Flux is involved in wave soldering in a number of areas, and quite a few issues arise relative to the qualification, handling, application and processing of flux:

Before soldering begins, verify that the flux is not past its expiration date, and that it has been stored correctly. Respect the storage guidelines on the flux datasheet and be sure that water-based fluxes have not been frozen during shipping.

For flux applications with a pump system, use the container provided by the flux supplier. In the case of a pressurized vessel where the flux must be poured into the vessel, take appropriate safety precautions and handle the flux away from the production environment.

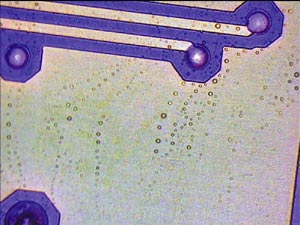

When applied on the solder side of the assembly, flux should wet to nonmetallic surfaces. It should be compatible with the solder resist (Figure 1).

FIGURE 1: Incompatibility between soldermask and flux results in oily residues on the solder side of the assembly after soldering.Flux should be preheated according to the specified topside board temperature, which can usually be found in the flux datasheet.

Flux must remove oxides that have been formed on the copper pads, components and other metallic surfaces.

During soldering, the flux should support the solder and prevent bridging when the board exits the molten solder.

Flux residues should be harmless and meet Bellcore and IPC SIR requirements, and Bellcore electromigration standards.

For the sake of machine maintenance, it is helpful if the flux can be removed easily.

Application methods. Flux application is a technology in itself. Different techniques are available; e.g., foam, wave, drum, spray fluxing. For today’s flux chemistries, spray fluxing using atomizing air nozzles is preferred. Its advantageous characteristics include uniform deposition; ease in controlling the amount of flux; and, because it is a closed system, no drift in flux density.

Spray fluxing forces flux in a vertical direction using atomizing air to create small droplets and to form a good interaction with the surface and penetration into the copper barrels.

The flux can be supplied by a pressurized tank system or a pump. For applications in which a gear pump is used, compatibility with some milky VOC-free water-based fluxes must be verified.

In most applications, the nozzle will be mounted on a transferring device. The speed of the nozzle movement should be adjustable as it needs to change when conveyor speed changes. The amount of flux can be varied by pump frequency or tank pressure. In addition, dedicated machines can spray specific areas of the assembly – very useful for boards mounted in pallets.

After spraying, the remaining flux should be removed from the nozzle head, otherwise the solvent will evaporate and crystals that are left behind will accumulate and cause clogging. One method of removal is to use a shot of pressurized air. The flux will be blown out of the nozzle head by venturi forces.

Flux characteristics. A good flux is active when the assembly leaves the liquidous solder, and acts to prevent bridging when solder drains away from soldered joints. For a double wave concept, it is important that not all the flux is washed off on the first wave-former.

The flux must provide good solderability. After soldering, it should leave a residue that is cosmetically acceptable and makes pin testing possible. A correctly set up solder wave will adequately adequately flush remaining flux residues. Regarding the process, the flux should leave no solder balls, but it should support through-hole penetration and prevent bridging.

Pb-free conversions, VOC legislation and taxes in different areas of the world are driving assemblers to water-based VOC-free fluxes. These fluxes are designed for higher temperatures, but are still under development. A number of brands are available, but only a handful perform equal or better than traditional alcohol-based fluxes. Water-based fluxes are nonflammable and have a shelf life of approximately 18 months. Freezing should be prevented during storage.

Gerjan Diepstraten is a senior process engineer with Vitronics Soltec BV (vitronics-soltec.com); gdiepstraten@nl.vitronics-soltec.com. His column appears monthly.

Press Releases

- Hon Hai Technology Group (Foxconn) Commits To New 5-Year Sustainability Roadmap Through 2030

- Amtech Electrocircuits Navigates Supreme Court Tariff Ruling

- Escatec Appoints Christa Schnider as Chief Sales Officer to Drive Global Growth

- PulseForge Makes Major Breakthrough Which Allows Flux-less Soldering in an Ambient Environment