What Goes in the PCB RFQ Checklist?

Want a quick response to the PCB assembly RFQ? Submit the full package of details.

Design projects that are actually completed with time to spare are few. We do what we can, but breaking new ground invariably uncovers a few snakes in the brush, and dealing with them takes time. That means that the next step – production ramp – starts behind schedule. At that point you need to get assembly quotes back ASAP so a choice can be made and the trigger pulled to get product flowing.

Some contract assemblers could provide a working number within a few days, but it would come with a list of caveats and unknowns and escalator clauses. Do you really want to commit to the program manager, the CEO, or worse, the market, with a number that guarantees a loss of profit (bid too low) or a loss of sales (bid too high)? Not if it could be avoided, of course. So let’s start by pulling together the documentation that engineering has, plus the implementation that marketing envisions, plus the ramp time the boss has in mind.

- Kit build (labor only), turnkey (labor and all materials), or a blend?

- Build, release, and EAU (estimated annual units/usage) quantities.

- BoM (bill of materials), including off-the-shelf part number, source, tolerances, alternatives, and count. Note those that are OEM-provided.

- If a component is obsolete, should it be broker-sourced, replaced or reengineered?

- OEM, EMS, or outside service to program ICs?

- PCB Gerber files, including board specification(s), quality level, panelization (x-outs OK?), and certifications (RoHS, ITAR, etc.).

- 3D CAD drawings with specs of custom parts (including the PCB) and current sources (if any).

- Assemblies supplied still in an array, as individual boards, or in final enclosures?

- Final assembly procedures required: conformal coating (type), potting, ultrasonic staking.

- Post-assembly procedures required: burn-in, temperature cycling (powered or unpowered), cycles and duration.

- QC testing: limited, AOI, fully functional; are test hardware and software provided?

- Golden sample and schematic available for test setup and aesthetic comparison?

- Packaging required (ESD, padded, consumer boxed, quantity per carton, etc.)?

- Percent shipment overage/underage acceptable?

Planning, quality and professionalism do not cost; they pay. Even with this list, questions might occur, but expect fewer interruptions to track down missing details and a more realistic cost, faster.

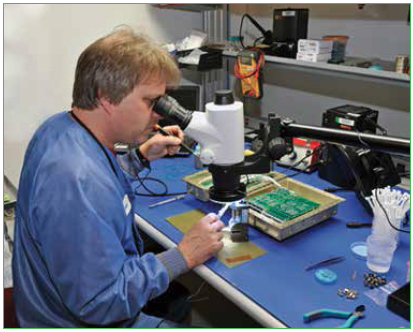

Figure 1. The EMS should take adders such as manual assembly into the equation.

Robert Simon is a veteran of technology development and marketing, having worked R&D and marketing for electronics, polymer, and metal companies, including Bayer AG of Leverkusen Germany and Battelle Memorial Institute of Columbus, Ohio, before founding USTEK Inc.; r.simon@ustek.com.

Press Releases

- AIM Solder Hires Francisco Rodriguez as Regional Sales Manager for Northeast Mexico

- The Test Connection, Inc. Adds Creative Electron Prime TruVision™ X-ray and CT System for Deeper Failure Analysis

- Kurtz Ersa Goes Semiconductor: Expanding Competence in Microelectronics & Advanced Packaging

- ECIA’s February and Q1 Industry Pulse Surveys Show Positive Sales Confidence Dominating Every Sector of the Electronic Components Industry