Viscom : Inspection Technologies Demonstrated at productronica in Munich

Hanover, Germany, October 1, 2021 - Viscom AG is presenting its latest inspection systems and solutions for the widest possible range of the electronics industry's testing requirements at this year's productronica. The company's experts will be on Stand A2.177 to explain to visitors how ultra-precise defect detection, exact measurements and intelligent evaluation during manufacture blend seamlessly together into perfect and sustainable inspection processes.

Networked manufacture of printed circuit boards and other electronic components requires an ever-increasing volume of 100% reliable inspection of product quality. Artificial intelligence and communication processes capable of linking production systems from multiple manufacturers are playing an increasing part in automated manufacturing and its processes. From November 16 to 19, 2021 Viscom will be taking advantage of Munich-based productronica to exhibit a quite unique range of its inspection technologies including state of the art solutions for the continuous statistical monitoring of individual manufacturing steps and support for standards such as IPC HERMES 9852 und IPC CFX. To the great delight of all concerned, all the latest information points towards this international trade fair being held "live" with visitors in the exhibition halls. There is every prospect of the trade fair going ahead thanks to appropriate hygiene arrangements and precautionary measures.

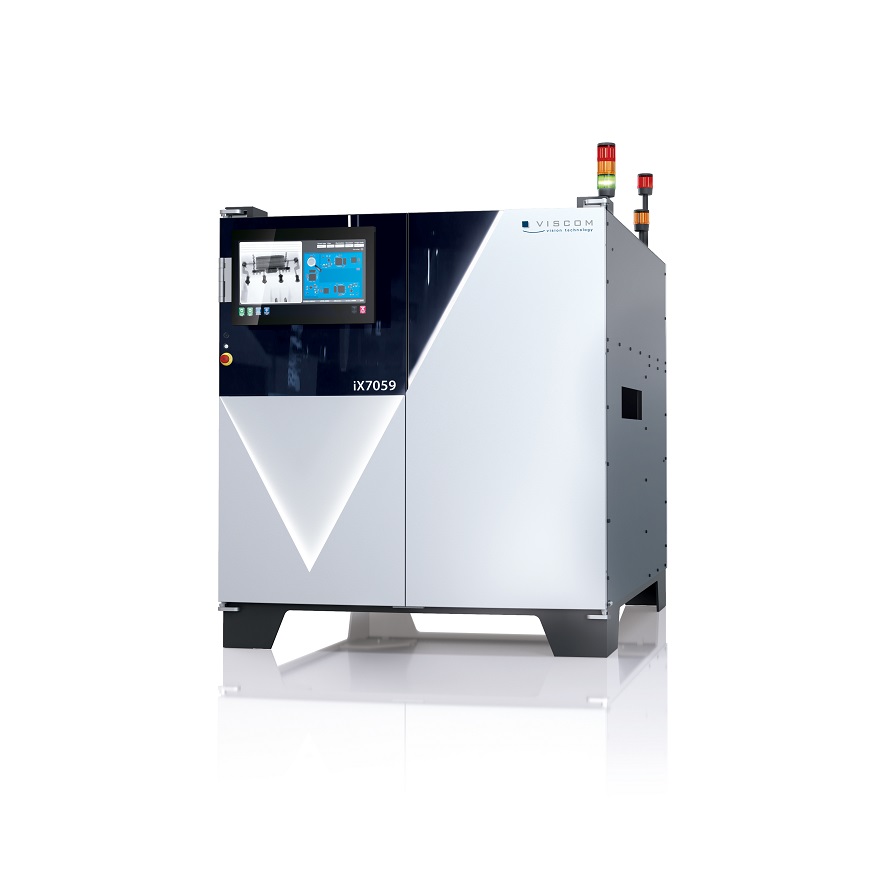

"We used the period of the pandemic to advance our innovations even further. During this time we concentrated in particular on the many and varied requirements in the field of 3D inline X-rays which is becoming increasingly important. As a consequence, we can now present some extremely sophisticated results in the area", stated Torsten Pelzer, Vice President Sales of Viscom AG. The biggest advances were made in the new Viscom iX7059 generation of inline X-ray systems which covers a broad spectrum of current and future requirements with, as one of its special features, flexible inspection concepts that have a much wider application than classic printed circuit boards. The 3D AXI system iX7059 Heavy Duty Inspection which belongs to this new generation will be on view at productronica. Its unique characteristic is its rapid handling of inspection objects weighing up to 40 kg and state of the art X-ray technology with powerful radiation. The iX7059 Heavy Duty Inspection is customized in particular to handle encased components and the requirements of power electronics. Typical uses include electromobility, telecommunication and renewable energies. As a result of these benefits and capabilities, the iX7059 Heavy Duty Inspection has already won a New Product Introduction (NPI) Award 2021 from CIRCUITS ASSEMBLY.

Thanks to features like a new generation of flat-panel detectors, the powerful computer tomography of the iX7059 systems provides excellent slice images and therefore also optimal presentation and very simple verification. The innovative dynamic 3D Evolution 5 imaging technology enables several hundred images to be captured from a number of different viewpoints in just a few seconds to obtain an unambiguous three-dimensional analysis. For example, voids in surface solder joints can lead to overheating if they are present in excessive numbers or if their diameter is too large as they prevent flawless heat dissipation. Their size and percentage incidence in the overall surface of the soldered joint are measured during inspection. Their number is also calculated with the greatest possible precision. Other types of defects which are detected by the iX7059 Heavy Duty Inspection are mechanical damage, twisted, missing and incorrect components as well as the degree of filling and pin heights in THT solder joints.

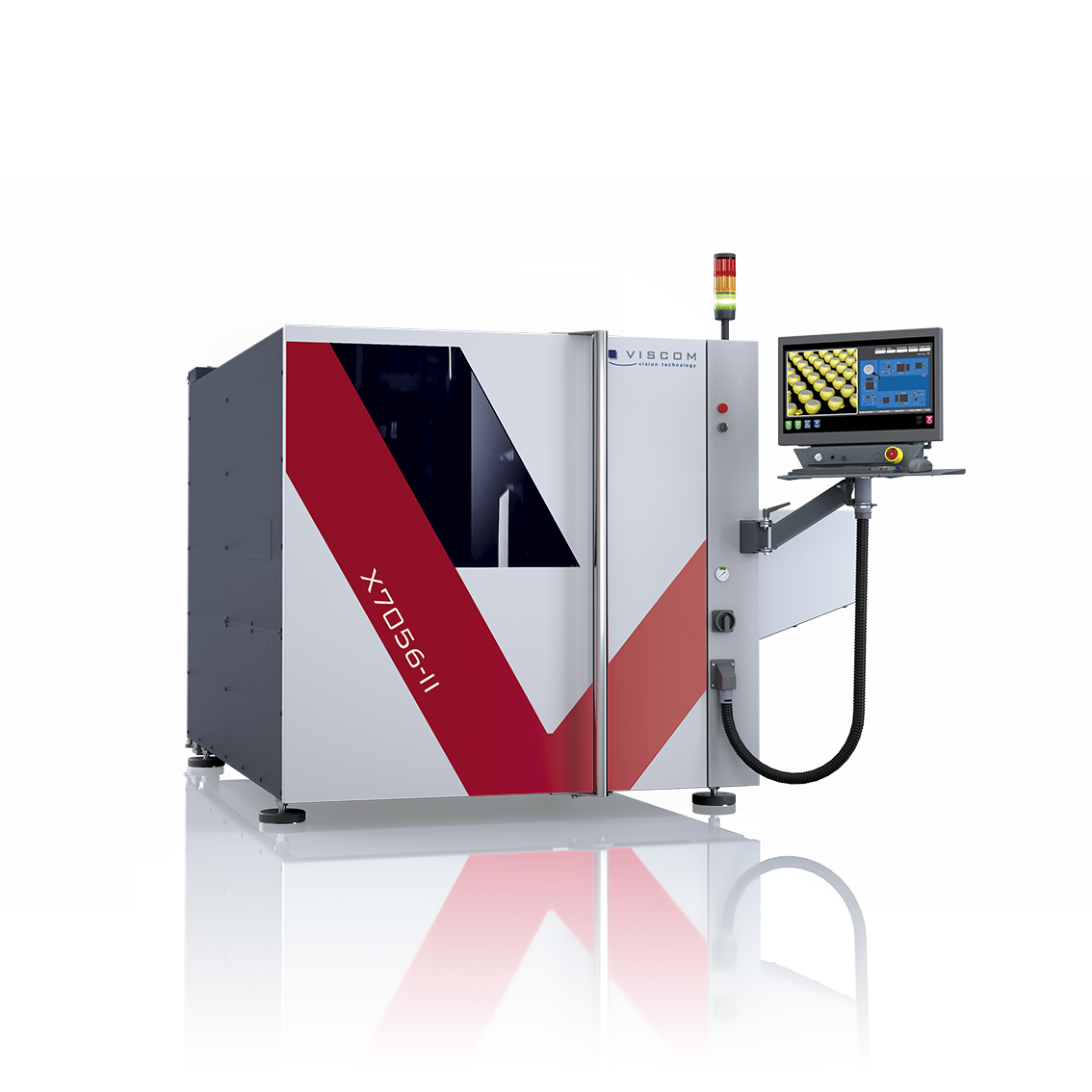

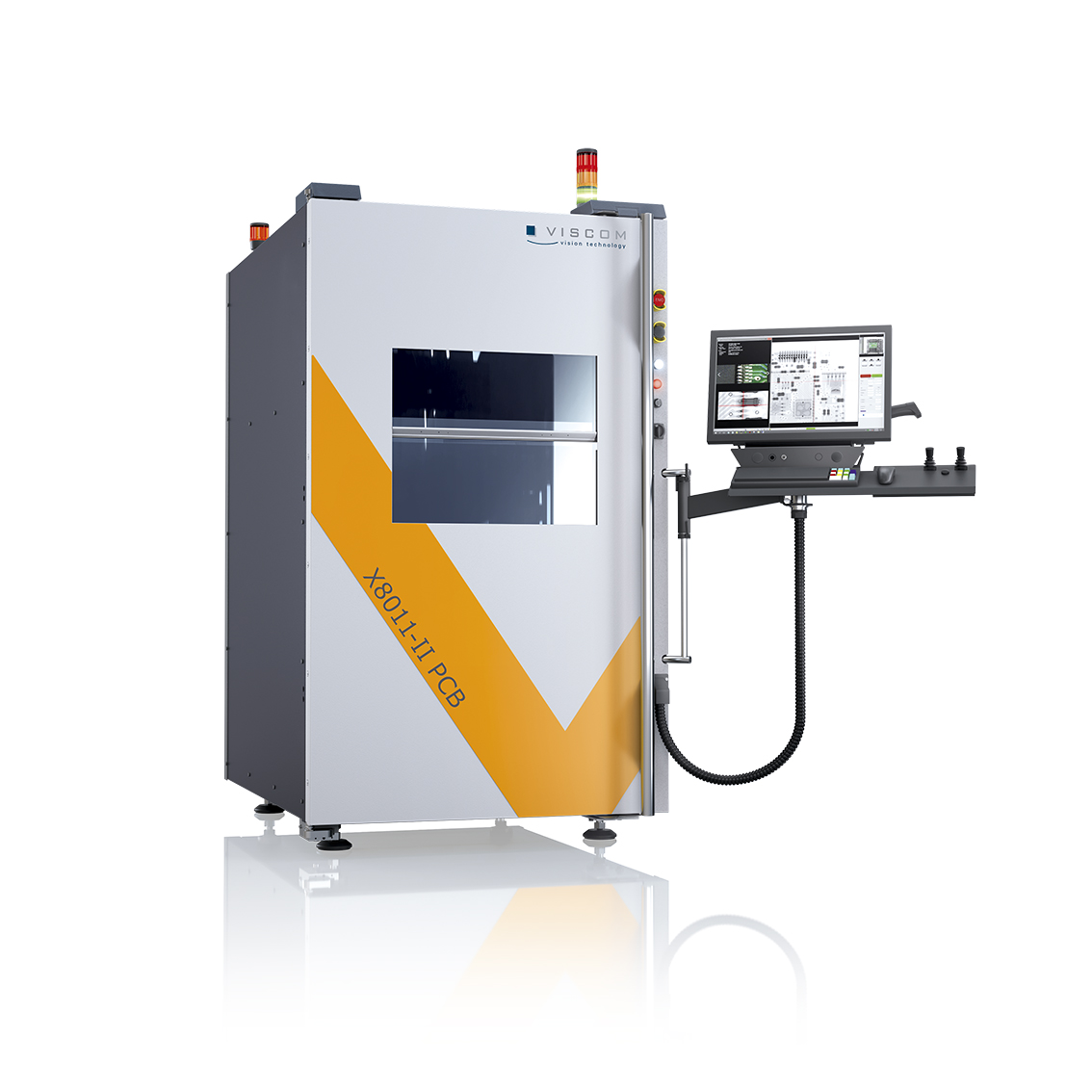

The 3D AXI system X7056-II, a winner of multiple international awards used for the rapid and accurate inline X-ray inspection of classic printed circuit boards will also be on show on Viscom's stand. It can also be configured as a combined inspection solution with a full range of supplementary 3D AOI sensor technology and is now in world-wide use by Viscom's customers for the most demanding inspection requirements. Visitors to the Viscom stand interested in an offline X-ray system for use in high-precision tasks such as the inspection of prototypes, random samples or small batch series will be able to learn about the multiple analysis functions and flexible sample handling capabilities of the MXI system X8011-II PCB.

Viscom will also be presenting the S3088 DT at productronica as a representative of its much sought-after 3D AOI and 3D SPI range. The compact system is designed for dual track operation and can be easily adjusted to a variety of track widths. It can also be used as a single-track version in which case it is able to inspect even the largest of printed circuit boards.

As well as a 3D sensor, the 3D AOI version of the S3088 DT includes eight high resolution angle view cameras and excellent orthogonal resolution, making accurate inspection of extremely small components down to 01005 possible. The very wide field of view guarantees extremely fast inspection for effective cycle time reduction. The inspection program generation is particularly intuitive and easy to use. Smart inspection algorithms accurately establish whether the solder joint of the smallest electronic component meets the specification or whether the solder is too thin. The system was one of the winners of the NPI Awards in 2020.

Viscom will also display its latest 3D SPI technology at productronica. Visitors particularly interested in learning more about it can request a demonstration of the multiple 3D SPI facilities for measurement, analysis and automated communication on the same S3088 DT where the 3D AOI functions will be presented. This is possible because the Viscom system is also available in a version for all the 3D SPI process steps that are very important in manufacturing.

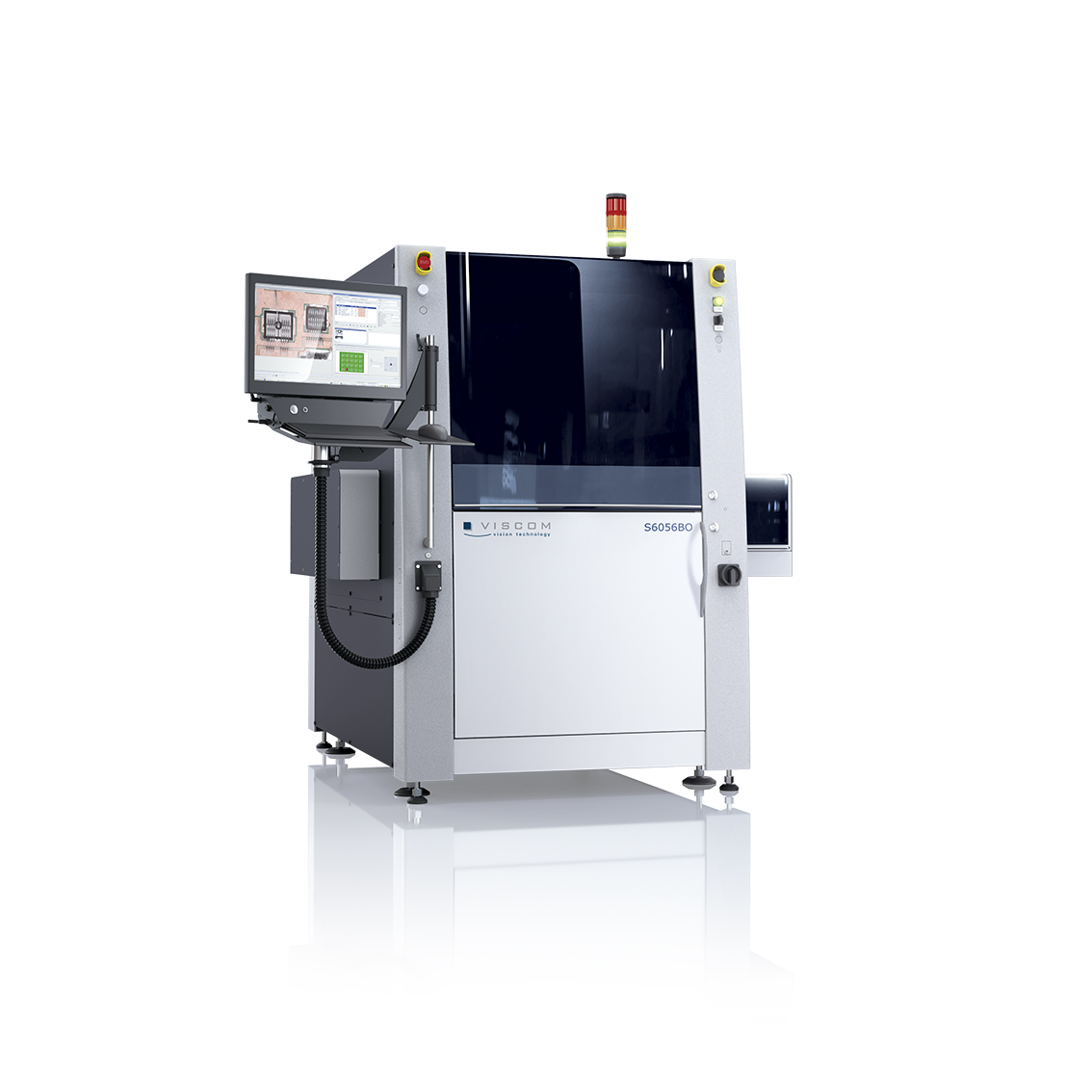

A special area of optical defect recognition is wire bond inspection. Viscom took the lead many years ago in this area with the scope of its inspection, and will also use the trade fair to publicize this technology with its latest future-oriented solutions: the company will use its S6056BO system to demonstrate the particularly advanced developments in the area of 3D inspection. These latest advances enable important additional information about the actual product quality to be gathered both for thick and thin wires. They can be employed very effectively in automated production lines and assist in reducing the number of false calls even further.

Press Releases

- Ben Maulorico joins Insight Polymers & Compounding as business development manager

- Strengthening SEMI Business (Semiconductor Back-End Process) in the European Market

- New White Paper Highlights How Shrinking Solder Powder Sizes Increase Cleaning Complexity in Advanced Packaging

- Distron Corporation Becomes First U.S. Electronics Manufacturer to Deploy Keiron’s LIFT-Based Precision Printing Technology