KIC in Booth #3101 at SMTAI: Solutions for Reflow and Wave Soldering Optimization, Inspection and Traceability

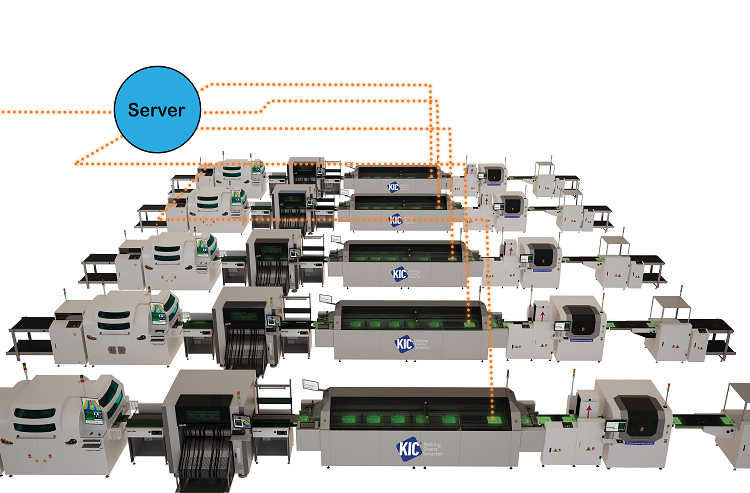

San Diego — October 2021 — KIC will exhibit in Booth #3101 at SMTA International, scheduled to take place Nov. 3 - 4, 2021 at the Minneapolis Convention Center in Minneapolis, MN. Along with Reflow Process Inspection (RPI) and Wave Solder Process Inspection (WPI), the KIC team will discuss NPI setup, process optimization for reduced defects, improved OEE, and their complete ecosystem of solutions for thermal processes.

KIC has solutions for challenges such as handling process audits, automating manual profiling and data reporting tasks, MES connectivity, Industry 4.0 implementation, NPI process setup, reducing solder defects (voiding, head in pillow, tombstoning) and more.

Electronics manufacturing today requires automated and real-time process control and traceability. Like SPI and AOI are for optical inspection, inspection of the production reflow temperature profile is a must. Could you imagine a line without SPI or AOI? Make sure you include RPI. Process control, traceability and quality solder joints can be delivered with real-time inspection capabilities and that is what KIC provides (and invented) for your thermal processes. This critical data should be a part of your overall Industry 4.0 smart factory solution to ensure all production through the oven is within specifications and that profile data is readily available for each individual board.

The latest addition to the thermal process inspection family is KIC’s WPI, bringing its award-winning technology and thermal experience to the wave solder process. Wave Process Inspection provides users with automatic profiling – including an industry first dwell time and parallelism measurement for each production board – real-time preheat and wave analytics, automatic SPC charting and more.

KIC’s 45 years of experience in automated process data collection, direct service and support offices in every region, and more than 25,000 systems in the field brings the most reliable, accurate and innovative solutions for electronics manufacturing thermal process tools.

Move toward the future with full line connectivity, flexible production, data analytics and real-time insight, making sure to include your ovens and wave solder machines. For more information about KIC, visit www.kicthermal.com.

Press Releases

- Altus Partners with Sellectronics to Enhance Manufacturing Capabilities with PVA Delta 8 System

- ITW EAE Celebrates Major Milestone in Domestic Manufacturing Expansion

- Micro Technology Services Selects PBT Works CompaCLEAN III for Advanced PCB Cleaning Performance

- Indium Corp. is Electrifying the Future with Advanced Materials Solutions at Productronica