A decade in, IPC-2581 Consortium members say the pursuit toward widespread adoption of the vendor-neutral standard was well worth the rigorous effort.

Few engineers working in electronics manufacturing today predate the first efforts to develop and implement an industry-wide standard for intelligent electronics data transfer.

As early CAD tools were introduced in the late 1960s and early 1970s, IPC launched a vendor-neutral effort to describe electronics design data from schematic through test.

To continue reading, please log in or register using the link in the upper right corner of the page.

The annual Women’s Leadership Program at SMTA International features two leading engineers.

SMTA International returns to an in-person format this year, with a virtual option, and the Women’s Leadership Program is in-person on Tuesday, Nov. 2! The past 18 months have been a time of reflection and transition for many of us. Many professionals are reassessing their career goals and career paths. In keeping with this trend, our 2021 WLP theme, “It’s good we are not all the same,” was chosen to encourage attendees to explore career transition options.

The WLP this year will focus on the success stories of women who have created varied career paths, applying core technical strengths to a variety of areas and succeeding consistently. Hear how their diverse career experiences have contributed to their long-term success. Our two distinguished speakers have blazed unique career paths and will share their stories with the audience.

To continue reading, please log in or register using the link in the upper right corner of the page.

A connected factory automates the AOI validation process.

Automated optical inspection (AOI) is typically used after solder reflow to detect missing components and defects. Performing a successful inspection of a panel is not enough, however. Manufacturing execution systems (MES) are used for process control and AOI data collection to ensure the following are accomplished:

- All prior routing operations passed.

- Valid test program is loaded on the machine.

- Test start- and end-times and test results are captured.

- Failed printed circuit boards (PCB) cannot advance in the production routing and must enter rework loop.

To continue reading, please log in or register using the link in the upper right corner of the page.

SAC 305 shows faster shear strength degradation than Innolot, while the surface finish has no effect.

When a solder joint is exposed to cyclic stresses, thermally activated diffusion in the bulk solder, metallization and initial intermetallic (IMC) may take place. The growth of the interfacial IMC helps relieve the residual stress induced in the solder joint, and the growth rate corresponds to the magnitude of stress induced.1 Solder joint strength also decreases during exposure to temperature variations. Therefore, shear testing is a useful method to assess solder joint strength degradation caused by thermal cycling.2

In part one3 of this series we showed the voiding, solder spread and thickness of the high-reliability Innolot alloy compared with SAC 305 alloy solder pastes using five different surface finishes. Part two discusses thermal cycling effects on the growth in IMC thickness and solder joint strength. This study included two commonly used solder alloys in paste form:

- SAC 305 (96.5%Sn, 3%Ag, 0.5%Cu) powder size distribution (PSD) type 4 with novel “CVP-390” paste flux

- Innolot (91.95%Sn, 3.8%Ag, 0.7%Cu, 3.0%Bi, 1.4%Sb, 0.15%Ni) PSD type 4 with the novel paste flux and five variations of surface finishes, including

-

- Organic solderability preservative (OSP) (MacDermid Enthone Entek Plus HT) using two thickness levels

- Immersion tin (Ormecon CSN)

- Immersion silver (MacDermid Enthone Sterling)

- Electroless nickel/immersion gold (ENIG) (MacDermid Enthone Affinity).

To continue reading, please log in or register using the link in the upper right corner of the page.

PCD&F’s annual salary survey reflects the consistency and stability of the PCB design industry.

To say much has transpired in the past year and a half is the understatement of all understatements. When we published the findings of our last designers’ salary survey in May 2020, we were still in the early months of the Covid-19 pandemic, many of us in the initial stages of a lengthy quarantine we thought was temporary. We were unsure how the virus would affect the world in the short-term, let alone the long-term – with regard to the health of loved ones and the economy as a whole, to name two of countless concerns. It will be many years before we fully comprehend the enduring global impact of this unmitigated health crisis, but if this year’s survey is any indication, one thing that has remained consistent is the PCB design engineering profession.

The US unemployment rate in July 2020 was 10.2%, and as of July 2021, it was 5.4%, according to the US Department of Labor.1 More specifically, for engineering occupations, the unemployment rate as of Jun. 30, 2020, was 6.1%, and at Jun. 30 this year, it was only 3.4%, BLS says, and the computer systems design and related services sector added 100,000 jobs in June alone.1

To continue reading, please log in or register using the link in the upper right corner of the page.

The indium additive relieves stresses that drive whisker growth.

Copper components in electronic packages (e.g., lead-frames, interconnects, integrated circuit leads and press-fit connector pins, to name a few) are often electroplated with tin (Sn) to prevent tarnishing and to facilitate subsequent soldering. With passage of time during storage or service, long whiskers grow from these tin coatings, causing electrical shorts between neighboring circuitry, posing serious reliability risks.1-3 This problem is particularly problematic in long-life applications, and failures have been reported in many arenas, including aerospace, nuclear power plants, automotive electronics, and military electronics systems, causing damages worth millions of dollars.

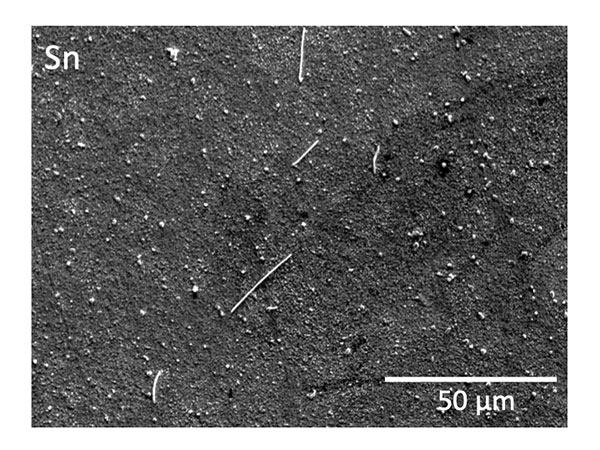

Figure 1. Surface of a copper substrate with a 3µm-thick electroplated coating, after ambient temperature aging for 1.5 months. The Sn version shows multiple whiskers.

A number of approaches to mitigate whisker growth have been pursued during the past 30 years, including additions of Pb, Bi, Au, Sb or Ge, or post-plating thermal treatments.4-8 These approaches mitigate whisker growth to varying degrees; however, none eliminates it. Over time, and under thermal-mechanical excursions, whiskers continue to grow.

To continue reading, please log in or register using the link in the upper right corner of the page.

Press Releases

- AIM Solder Hires Francisco Rodriguez as Regional Sales Manager for Northeast Mexico

- The Test Connection, Inc. Adds Creative Electron Prime TruVision™ X-ray and CT System for Deeper Failure Analysis

- Kurtz Ersa Goes Semiconductor: Expanding Competence in Microelectronics & Advanced Packaging

- ECIA’s February and Q1 Industry Pulse Surveys Show Positive Sales Confidence Dominating Every Sector of the Electronic Components Industry