Selective Conformal Coating

As printed circuit boards become smaller, the challenges faced when coating them grow. It is increasingly important that products are protected from damage from moisture, dust and other dirt, which can lead to interference and even cause the board to fail.

In the protective coating (conformal coating) process, printed circuit boards are protected from dust and environmental factors by applying a targeted protective coating, thus ensuring their reliability. Being able to protect electronics is of critical importance in sectors where faultless function is essential.

Theoretically, any assembled PCB can be coated, although, depending on the plant’s system, the board size and how it is arranged may need to be reviewed beforehand.

Because of the technically complexity and extreme climatic changes involved, protective coating is essential in air and space travel, ship building, automotive engineering and military technology. But this coating is also very useful to protect the function of electronics that come in contact with dirt or other environmental factors. Therefore the coating is used in all branches of the electronics industry, such as alarm technology, telecommunications, industry controls, traffic technology, railway technology, medical engineering, food engineering and many other areas.

The conformal coating line consists of a coater, handling equipment and a drying or annealing oven. It is important to have a detailed, regulated temperature profile to prevent blistering or other flaws in the surface of the coating material.

The first step in conformal coating is choosing the coating material. Several factors must be considered, including the protection required, whether the selected coating can be processed in the line given its application, drying and cycle time, and cost-effectiveness. Popular coatings are epoxy, urethane, silicone and acrylic. Choosing the right coating requires experience and technical knowledge.

After choosing the best coating materials for the mechanical, chemical and electrical requirements of the board, the coating process itself can begin. There are different methods for applying the coating on to the board, such as squirting, spraying, dipping, flooding, dispensing and vapor deposition.

As most boards contain components that cannot be coated, the standard today is selective spray coating. Diverse parameters must be considered, as not every coating can be applied with every process. One problem, for example, is that many of the nozzles in selective spraying equipment become clogged quickly, so highly viscose coatings cannot be used and changing coatings can be problematic. Another important factor is the layout of the board, which should be designed for coating beforehand to ensure the most effective and cost-efficient coating. This is because the spaces in very high or tightly packed circuit boards cannot be sprayed with every nozzle.

After the protective coating has been applied, the next step is the drying process. This process should take place at a regulated temperature profile so that the results are reproducible and reliable. Incorrect temperature profiles or hardening the coating too quickly can lead to several faults, such as blistering, holes or the “orange peel” effect.

Because of the complexity and the interaction of the individual parameters and processes, the customer should agree on the desired result and the best solution for each end-product with the equipment manufacturer and material supplier.

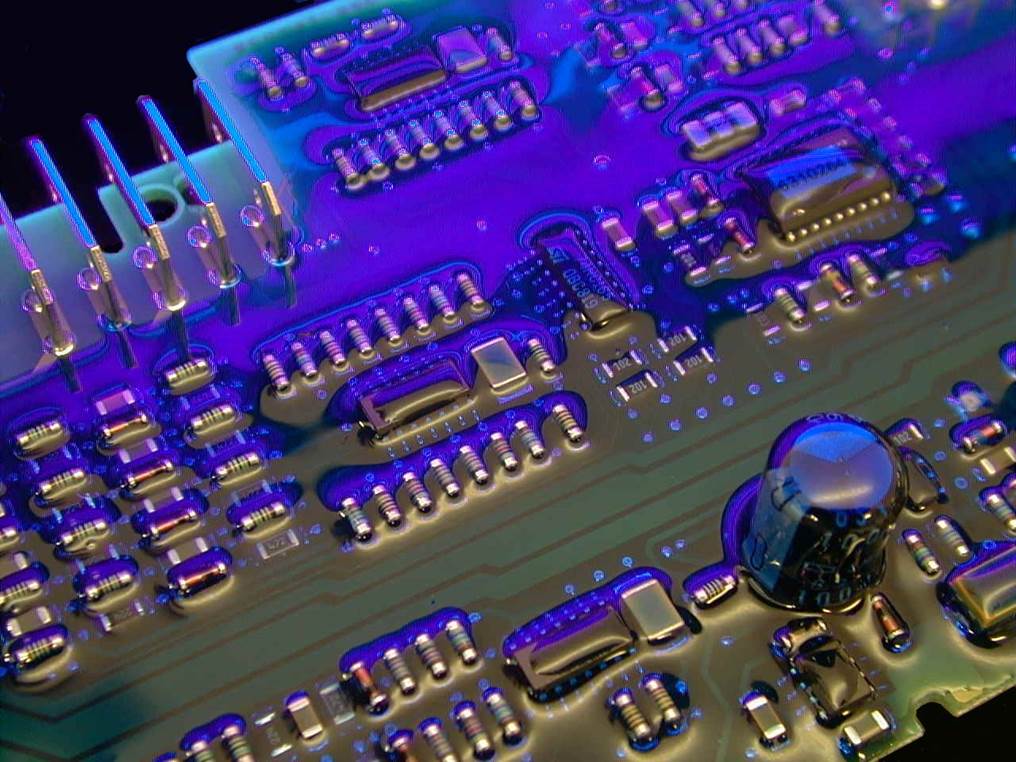

Figure 1. Fluorescent protective coating under black light.