Revamping the SMTA Miniaturization Test Vehicle

Rev. 3.0 will incorporate user input. What should be on the next layout?

The current SMTA Miniaturization Test Vehicle was released in 2018 and is projected to have an effective lifespan of three to five years. Its design has served the SMT community well – and will continue to do so with an updated layout, bill of materials (BoM) and associated programming and analysis files slated for release in late 2022.

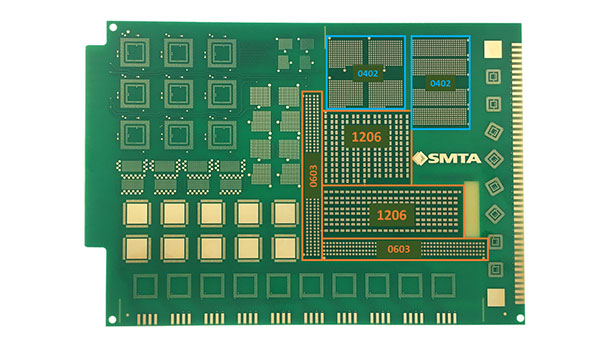

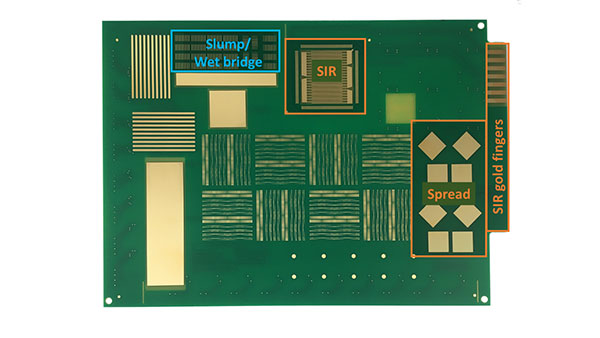

The board is used for standard tests, such as solder paste selection, wipe frequency and pad or aperture design, which will remain the same in the new revision, albeit with some components removed and others added. FIGURES 1 and 2 show the top and bottom sides of the board with the footprints that will be removed outlined in orange, and ones that may be removed outlined in blue:

- The 1206 and 0603 components will be completely eliminated, opening up several square inches of real estate on the populated side of the board.

- The QFN layout will avoid copper pads on the opposite side to make x-ray analysis easier.

- The SIR coupon will be removed, thereby eliminating the need for the gold fingers on the short edge of the board, which in turn will eliminate the notch that requires machine board stop adjustments for the unpopulated side. It will also free up about 6 sq. in. of real estate for print or reflow tests.

- At least one set of the fine resolution spread tests will be removed, freeing up even more space on the unpopulated side.

FIGURE 1. SMTA Miniaturization Test Vehicle populated side.

FIGURE 2. SMTA Miniaturization Test Vehicle unpopulated side.

With all the newly available real estate, what will we add to the board? That’s up to the SMTA community. What do users want on the next layout? Here are some ideas we’ve received so far:

- More pad and aperture sizes for 01005s; built-in DoEs.

- More pad and aperture sizes for 008004s; mask-define some 008004s and build in DoEs.

- D-paks for voiding tests.

- 0.4mm TSSOPs.

- More BTCs of different sizes; thermal vias in center pads.

- Stagger BGA layouts to mitigate “leading-edge effect.”

- More 0.3 BGA pad configurations.

- Rotational placements at various angles.

- LED footprints.

- Areas to dispense and measure adhesives or other additive materials.

- Cu pillar flip chips.

Should the 0402s stay or go? What about the wet bridge test patterns? I’m asking for user input through the month of May, and layout efforts will begin this summer. SMTA Rev 3.0 is planned to make its debut Oct. 31 - Nov. 3 at SMTA International 2022 in Minneapolis.

Have some ideas? Email me at chrys@sheaengineering.com. I look forward to hearing from you.

is president at Shea Engineering Services (sheaengineering.com); chrys@sheaengineering.com.