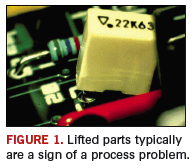

Lifted Components

Published: 25 March 2010

by Paul Lotosky

If parts are coming off the board, check the conveyor speed and lead lengths.

When components show lifting during wave soldering, the following mitigation steps might prove helpful.

Primary process setup areas to check:

- Conveyor speed too fast. Slowing the conveyor will increase the immersion time in the wave and overcome thermal mismatch or demand.

- Incorrect lead length: Shot leads may shift and can pop out of the hole.

- Board flex or warpage.

- Other things to look for in the process:

- Solder wave height too high.

- Conveyor vibration.

- Board incorrectly seated.

- Solder wave uneven.

- Conveyor angle too high.

- Defective fixture.

- Excess flux blow-off.

- Early removal of board.

Other things to look for with the assembly:

- Improper board handling.

- Component lead length too long.

Things to look for with the board design:

- Poor pallet design.

Paul Lotosky is global director - customer technical support at Cookson Electronics (cooksonelectronics.com); plotosky@cooksonelectronics.com. His column appears monthly.

Press Releases

- Does Over-Reliance on X-Ray Inspection Create Unintentional Component Damage?

- Kitron Autonomous Defence Systems Agreement Increased to EUR 12M

- Keiron Printing Technologies Appoints BarTron, Inc. as Sales Representative for Midwest and Ohio Valley Regions

- CalcuQuote rebrands within Elisa Industriq, strengthening a unified market presence