You’re Grounded!

Setting up the electrostatic discharge workstation.

Setting up an ESD workstation or area to reduce the risk of ESD in the workplace is simply a matter of understanding your processes and installing the necessary and proper ESD avoidance materials. However, simply installing ESD avoidance materials and items without understanding how they will impact the processes may cause misunderstanding and misuse. It is always best if ESD avoidance materials and items work seamlessly with your processes. This means that you can control electrostatic charge generation and charge accumulation and any subsequent discharges that are above your predetermined tolerance level without doing anything unusual.

The first consideration, as stated clearly in ANSI/ESD S20.20 (S20.20), is to understand the ESD sensitivity of the materials or components involved in your processes. Once you have settled on that level, the controls can be efficiently designed. The first rule in the design of an electrostatic protected area (EPA) is, if personnel are handling unprotected product (outside of protective containers or packages), establish a means of personnel grounding. Along with grounding people, some sort of protective work surface is generally needed upon which to place the sensitive product while performing the necessary operations.

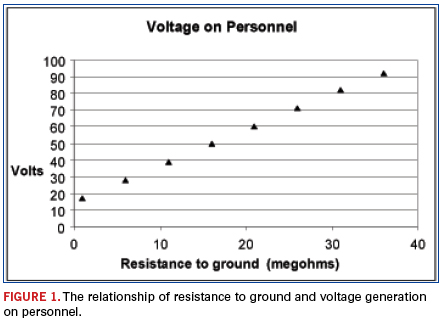

The design of the grounding system depends on your needs. A main consideration is whether personnel have to be mobile. If they require mobility, a floor and footwear system that provides a path to ground through the personnel is generally recommended. Today, a resistance to ground specification of <3.5 x 107Ω (3MΩ) is considered optimum for most applications where >100V Human Body Model (HBM) parts are handled. It is also important to have an understanding about charge generation characteristics of the floor and footwear system. Make certain that the peak voltage generated by contact and separation of footwear from the floor does not exceed predetermined limits (generally >³100V measured on the person for most applications – see ANSI/ESD STM 97.2). The next release of S20.20 (expected late in 2012) will place more emphasis on the voltage on personnel and make the STM97.2 method the main test procedure for qualification of a floor and footwear system. If extremely sensitive products are processed, the resistance to ground level and the voltage generation level must be set lower. A rule of thumb in common use today is to reduce the resistance to ground level to <1 x 107Ω (10MΩ) and the voltage level to <50V for extremely sensitive parts. Increased resistance to ground permits higher charge generation and accumulation (Figure 1).

If personnel are seated to do their work, a wrist strap type grounding system must be employed. The rationale is that seated personnel rarely have their feet in solid contact with the floor. Even if an ESD control floor and footwear system are in place, seated personnel have to use a wrist strap or a proven and documented equivalent type of grounding system to ensure consistent and

continuous grounding. The resistance to ground specification for a wrist strap grounding system is the same as stated above for a floor-footwear system: ≤35MΩ for a 100V HBM program and ≤10MΩ for more sensitive applications.

Verification that the grounding system is functioning correctly is of major importance. In general, the higher the risk or cost of failure, the more the grounding system must be checked. Most companies establish a minimum of one test per shift for personnel grounding. Many companies will require a retest each time a person returns to their workstation. In high-reliability or high-risk situations, continuous monitoring may be required. Once only required for military electronics, today many companies find it cheaper to use continuous monitoring, since it reduces test time and record-keeping. Personnel are taught to stop work when the wrist strap monitor sounds an alert, so that the problem can be fixed immediately.

Verification that the floor and footwear system is functioning according to specifications is usually done with less frequency than a wrist strap system. ESD control shoes are not prone to change as much as wrist straps, but do not get complacent. Shoe grounding straps can be installed incorrectly, so they should be checked each time they are put on to make sure they are working correctly.

Properly installed floors do not change much over time, but can get ruined in a heartbeat with improper maintenance. Putting the wrong wax on a conductive floor may make it look nice, but will no doubt alter the performance. Most companies require a retest of a floor after cleaning or maintenance to make sure the electrical properties are unchanged.

A work surface can be a tabletop, workbench, conveyor, machine surface or any other place that holds products during a process; thus, the mechanical and physical requirements for a work surface will vary with each application. In general, the main electrical requirement of an ESD protective work surface is to permit a charge to drain from conductive or dissipative items placed on that surface. How rapidly the charge drains depends on the resistance of the ESD protective work surface and the contact resistance between the surface and the item. If the item is a charged ESD susceptible part, care must be taken to avoid Charge Device Model (CDM) issues. However, proper handling of parts will reduce charge generation and charge accumulation on the part and thus reduce CDM issues at the same time. Many companies operate facilities with very conductive work surfaces (e.g., stainless steel benches) with no ESD issues.

Contact The ESD Association (esda.org); info@esda.org.

Press Releases

- PulseForge Makes Major Breakthrough Which Allows Flux-less Soldering in an Ambient Environment

- Panasonic Connect publishes case study on delivery of its surface mount technology (SMT) equipment to Dixon Technologies, one of India’s largest EMS companies

- CE3S and Desco Industries Announce May 2026 ANSI/ESD S20.20-2021 Certification Webinar Series

- Kurtz Ersa Goes Semiconductor: Expanding Competence in Microelectronics & Advanced Packaging