When to Downsize Solder Paste Powders

Smaller components do not always need a smaller paste.

As components shrink in size, the demand for finer solder pastes increases. But the selection of solder paste is not just about matching component size; it’s also about optimizing printing and reflow processes to prevent defects and ensure reliability.

Here we explore the significance of solder paste powder size, particularly when and why manufacturers should consider downsizing from standard types to finer alternatives.

The exact method for creating solder powder, and ultimately solder paste, can vary significantly from one manufacturer to another. These differences in production methods can lead to very different outcomes when printing with a particular paste size.

In other words, you can end up with entirely different results when using a Type 5 paste from one manufacturer compared to another. Moreover, the inherent variation within a given solder powder production process will have a greater influence on the paste’s performance the smaller the particle size gets.

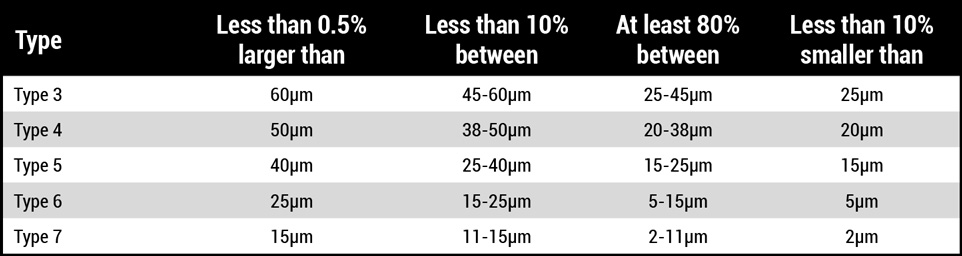

IPC standardizes particle size classification, but it still permits significant variation. IPC standards specify that only 80% of particles for a given type must fall within the nominal range (Table 1). This leaves room for differences in particle size distribution among manufacturers, which can significantly affect solder paste performance, including printability, reflow behavior and reliability.

Table 1. Particle Distribution Limits Per IPC J-STD-005A

When considering whether to downsize solder paste, consider the size and spacing of components, the production environment and settings and the potential challenges that can come with smaller powders.

In general, the smaller the paste, the more challenging the process. Because of this, the ultimate success of the process becomes increasingly dependent on all the variations in solder paste production methods described above.

The 5-Ball Rule and Its Implications

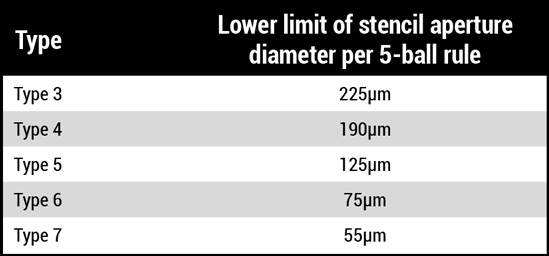

A common heuristic used to determine what powder size to use is the so-called “5-ball rule.” The 5-ball rule suggests that the smallest stencil aperture should be at least five times the diameter of the solder paste’s largest particles (Table 2).

Table 2. Lower Limits for Stencil Aperture Diameters

For instance, with Type 4 solder paste, where particles range up to 38µm, the smallest printable aperture would be around 190µm/0.004". As assemblers move to to finer powders like Type 6, with particles as small as 5-15µm, however, the practical applicability of the 5-ball rule becomes uncertain. This is because the extremely small particle sizes and tighter spaces have not been thoroughly tested, thus the rule might not hold true or require adaptation for these advanced types.

Let’s Get Small?

Downsizing to a smaller powder comes with tradeoffs, especially at the smallest powder sizes, namely:

- Smaller powders are more difficult to produce and come with a higher price.

- Smaller powders have a greater surface area to mass ratio and more potential for oxidation. This shortens shelf life and makes them more sensitive to process parameters, with requirements for nitrogen reflow for Type 6 and smaller.

- Manufacturing methods differ from one supplier to the next, so there can be substantial variation in the quality of a particular powder size in terms of sphericity of particles and particle size distribution. These variations can lead to unanticipated issues and defects.

- Stencil design adaptations might be needed for finer powders to avoid issues like stencil clogging or insufficient paste release. This involves considering stencil thickness, aperture size and wall smoothness.

- In general, the smaller the powder, the smaller the process window, which means settings such as squeegee pressure and speed must be carefully dialed in.

Bigger is Better

Because of the significant tradeoffs from downsizing, if an application is near the threshold suggested by the 5-ball rule, it may be prudent to stick with the larger size. In fact, at AIM, we have had several situations where our Type 4 paste outperformed Type 5 paste in situations that were borderline when it came to the downsizing decision.

As an example, suppose the boards to print contain 01005 components. IPC-recommended stencil apertures for these components are 175 x 250µm, which may be outside of what Type 4 paste should be able to print (≥190µm).

With a little ingenuity, however, it’s also possible to use a rounded square aperture design with a side length of 190µm or slightly larger for these components. This aperture shape maximizes volume while improving transfer efficiency.

In this scenario, transfer efficiency can be further maximized by using a nanocoated 4-mil or even 3-mil stencil. Hence, if 01005s are the smallest components on a given board, Type 4 paste can work with few unintended side effects.

Half-Size Solder Pastes

Some pastes are labeled Type 4.5 or Type 5.5, begging the question whether it might be a good idea to switch to a half size if their components are right on the edge, such as the case described above.

No IPC specifications define what these half types are, however. While it may be expected that a paste labeled Type 4.5 has a particle size range between that of Type 4 and Type 5, in fact it could be larger, smaller or simply broader – as would happen were Type 4 and Type 5 powder mixed together.

When considering a half-size paste, get a clear indication from the manufacturer as to the particle size distribution before proceeding.

Conclusion and Recommendations

Selecting the appropriate solder paste type is crucial for achieving optimal assembly outcomes. The 5-ball rule offers a foundational guideline for this choice, but it's essential to consider the broader context of your manufacturing processes and component requirements.

Before downsizing solder paste, assess the potential benefits against the associated challenges, such as increased oxidation or reflow issues. Optimization of existing processes with the current paste type may alleviate the need for downsizing, maintaining production efficiency and product quality.

is content specialist at AIM Solder (aimsolder.com); gtowell@aimsolder.com.

Press Releases

- Hon Hai Technology Group (Foxconn) Commits To New 5-Year Sustainability Roadmap Through 2030

- Amtech Electrocircuits Navigates Supreme Court Tariff Ruling

- Escatec Appoints Christa Schnider as Chief Sales Officer to Drive Global Growth

- PulseForge Makes Major Breakthrough Which Allows Flux-less Soldering in an Ambient Environment