Keeping Electronics Cool

Types of TIMs and their application methods.

As demand for high-performance electronic devices continues to grow, managing heat dissipation effectively has become a critical challenge. Thermal interface materials (TIMs) are pivotal in ensuring efficient thermal management by facilitating heat transfer between heat-generating components and heat-dissipating devices. Here, we examine the various types of TIMs and their application methods, including insights into modern dispensers and the advantages and disadvantages of these methods in electronics manufacturing.

In the electronics industry, thermal interface materials are integral to various applications, including processors and GPUs, power electronics, memory modules, automotive electronics and telecommunications. For example, TIMs are used between processors or GPUs and their heatsinks to ensure efficient heat transfer, preventing thermal throttling and enhancing performance. This issue has been magnified by the recent surge in AI-related hardware, which often requires significantly more processing power and generates more heat that must be managed effectively.

Other high-power components, like power transistors and LEDs, also generate significant heat, and TIMs help maintain optimal operating temperatures, prolonging the lifespan and reliability of these components. Memory chips, especially those in high-performance applications, benefit from TIMs as they manage heat dissipation and maintain thermal stability.

In automotive applications, TIMs are used in electronic control units (ECUs) and other high-power components to ensure reliable performance under extreme conditions. TIMs are also used to manage the heat generated by high-power amplifiers and similar devices in base stations and other telecommunication systems. These materials are a critical element in ensuring efficient thermal management, which helps maintain the performance and longevity of the equipment.

TIM Types

Thermal interface materials come in several forms, each tailored to specific applications and performance requirements. The primary types of TIMs include thermal adhesives, thermal gap fillers such as greases and pastes, as well as thermal pads, phase change materials (PCMs) and thermal tapes.

Thermal greases and pastes are highly viscous compounds that fill microscopic air gaps between surfaces, enhancing thermal conductivity. They are widely used due to their performance and ease of application.

Thermal pads are solid, compressible materials typically made from silicone or other polymers infused with thermally conductive fillers. They are user-friendly and ideal for applications where rework and reusability are important. Thermal adhesives serve a dual function: They provide thermal conductivity while also acting as adhesives, bonding components together. Such adhesives are commonly used in applications where mechanical fastening is impractical.

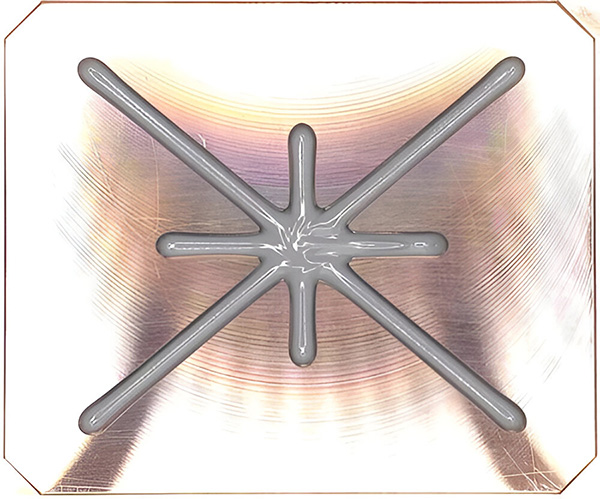

Figure 1. Thermal interface materials come in various forms tailored to specific applications and performance requirements.

Thermal tapes are double-sided tapes with thermally conductive properties, offering both adhesion and thermal management. They are suitable for lightweight components and applications requiring quick assembly.

Phase change materials (PCMs) are a more recent concept for electronic systems cooling. PCMs are used to absorb peak energy loads, such as during power-on operation, and then reject that heat load at another time, which can be useful for applications requiring repeated thermal cycling.

Application Methods

The effectiveness of a TIM depends not only on its material properties but also on the application method. Common application methods include manual application, automated dispensers, stencil printing and the use of thermal pads and tapes.

Manual application of TIMs does not require specialized equipment, making it a low-cost and flexible option. It is suitable only for small-scale operations and prototype volumes since it is labor-intensive. This method also has an increased likelihood of human error and uneven distribution, which can negatively affect the thermal performance of a system.

Automated dispensers are programmed to apply specific amounts of TIM in precise locations. This significantly reduces application time and aids precise, repeatable and consistent application of TIMs, which is critical for high-performance and high-volume manufacturing. These systems do require an investment in equipment and maintenance and typically involve programming and regular calibration, which can be challenging for small operations.

Traditional screen printing uses a stencil to apply a specific amount of thermal paste or adhesive. This method ensures consistent thickness and coverage to achieve the desired thermal conductivity. It is suitable for high-volume production with minimal waste but requires precise alignment and setup, which can be time-consuming. It is also limited to specific designs with no height variance, and any adaptation or change requires an entirely new custom-made stencil, making it significantly less flexible.

Thermal pads, tapes or PCMs cannot be dispensed, which typically makes them more difficult to work with, especially in a high-volume environment. They can, however, be easily repositioned or replaced, making them well-suited for rework and repair. These materials generally have lower thermal conductivity compared to greases and pastes and require consistent pressure to maintain effective thermal contact.

Automated Dispensers

Modern dispensing systems have updated the precision and efficiency of applying of thermal interface materials. These systems utilize advanced technologies to cater to the stringent requirements of the electronics industry. Highly accurate positioning systems ensure the accurate movement of the dispensing head, while pressure sensors and feedback loops monitor the material flow, adjusting parameters in real time to maintain consistency.

TIMs, especially thermal greases and pastes, often have high viscosity, posing challenges for consistent dispensing. They often have a consistency of caulk or something even resembling Play-Doh. Silicone greases, for instance, are inherently thixotropic, which means they can become less viscous under applied pressure. Advanced dispensers are equipped with features to handle these materials effectively. Heated dispensers, for example, maintain the TIM at an optimal temperature to reduce viscosity, ensuring smooth flow and accurate application. Additionally, high-pressure systems with precision auger pumps that regulate the flow rate and volume of the material can dispense viscous materials without clogging or interruptions, maintaining a steady and reliable application process.

TIMs are often abrasive and can contain aluminum oxide or even ground diamond. Automated dispensers need to be robust and well-engineered to minimize wear and tear while constantly delivering precise amounts of TIM with high repeatability.

One of the key features of advanced dispensers is their capability to apply the TIM in specific patterns and quantities tailored to the unique requirements of each application. This level of customization is particularly beneficial in high-volume manufacturing in areas such as artificial intelligence, 5G telecommunications and electric vehicles, where different components may require varying amounts of TIM. Software interfaces allow operators to create and store multiple dispensing profiles, ensuring quick changeovers and minimal downtime.

TIMs are essential for managing heat in electronic devices, ensuring their reliability, performance and longevity. As electronic components continue to shrink in size while increasing in power and complexity, effective thermal management becomes even more critical. Selecting the right TIM and application method requires consideration of various factors, including thermal conductivity, ease of application and cost.

The application of TIMs is increasingly reliant on automated state-of-the-art dispensers due to their ability to deliver precise, consistent and repeatable results. These systems are vital for high-volume electronics manufacturing, where the accuracy and uniformity of TIM application can significantly affect device performance and yield rates while reducing waste and minimizing the risk of human error. As the demand for high-performance electronics grows, the role of TIMs in thermal management will remain crucial, driving innovations in both materials and application technologies.

is senior applications engineer at GPD Global (gpd-global.com); npreslan@gpd-global.com.

Press Releases

- Hon Hai Technology Group (Foxconn) Commits To New 5-Year Sustainability Roadmap Through 2030

- Amtech Electrocircuits Navigates Supreme Court Tariff Ruling

- Escatec Appoints Christa Schnider as Chief Sales Officer to Drive Global Growth

- PulseForge Makes Major Breakthrough Which Allows Flux-less Soldering in an Ambient Environment