Sonoscan Debuts C-SAM Model DF2400Z Acoustic Micro Imaging System

Published: 16 January 2015

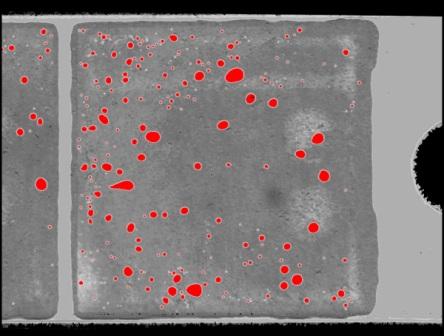

C-SAM model DF2400Z automated acoustic micro imaging system images and analyzes IGBT module defects. Incorporates inverted transducer. Once a recipe for scanning has been defined, the factory automation interface controls the operation. A conveyor loads two IGBT modules onto the two system stages.  Two ultrasonic transducers raster-scan each module. Ultrasound is pulsed into the module. Echo signals are received from gap-type defects. Accepts and rejects are stacked in separate locations. Accept/reject criteria are written by the user. Acoustic images reveal what type of rework is needed. Finds gap-type defects. Can image tilting and warping of module elements such as rafts.

Two ultrasonic transducers raster-scan each module. Ultrasound is pulsed into the module. Echo signals are received from gap-type defects. Accepts and rejects are stacked in separate locations. Accept/reject criteria are written by the user. Acoustic images reveal what type of rework is needed. Finds gap-type defects. Can image tilting and warping of module elements such as rafts.

Sonoscan, www.sonoscan.com

Press Releases

- 2026 IEEE Electronic Components and Technology Conference Student Innovation Challenge Pre-registration Deadline Extended to January 11, 2026

- PCBsync PCB Assembly Introduces Full-Scale Electronic Manufacturing Service

- Magic Leap Partners with Pegatron for AR Glasses Components Production

- TEXMAC/Takaya Appoints ARK Mfg. as New Rep in Arizona