Viscom Rolls Out 3D MXI System X8011-III

X8011-III automated 3D MXI resembles exterior of iX7059 systems.

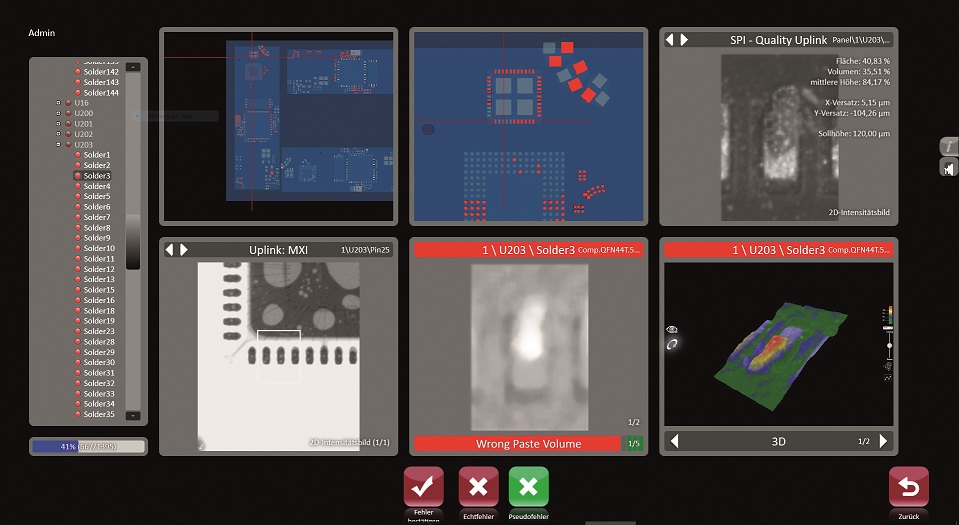

Includes extensive analysis functions and intuitive operation. To inspect THTs or identify voids in surface soldering, analysis parameters reportedly can be selected and adjusted quickly and flexibly during operation. Provides overview of tools required to create inspection plan for automatic x-ray inspection. If shadowing of interfering components prevents optimal image result, 3D reconstructions can be achieved with computed tomography. Options are available as part of XVR software. Individual layers of irradiated object provide nondestructive information on whether or not manufacturing defect is present. Smart networking is integrated into production line. Overlap between MXI and AXI properties is evident. Inspection data from 3D SPI and post-reflow systems (3D-AOI and 3D-AXI) can be compared at verification station with detailed 3D-MXI results. Manual x-ray system reads inspection plan from production line to automatically approach only those positions on assembly that need to be verified. Reports with result and system data are generated automatically, including radiation dose information. Is reportedly ideal for inspecting radiation-sensitive components.

Viscom

viscom.com

Register now for PCB East, the largest electronics technical conference and exhibition on the East Coast. Coming in April to Marlboro, MA.

Press Releases

- Hon Hai Technology Group (Foxconn) Commits To New 5-Year Sustainability Roadmap Through 2030

- Amtech Electrocircuits Navigates Supreme Court Tariff Ruling

- Escatec Appoints Christa Schnider as Chief Sales Officer to Drive Global Growth

- PulseForge Makes Major Breakthrough Which Allows Flux-less Soldering in an Ambient Environment