Pop Goes the Via

An insufficient bond between copper layers can lead to electrical test failure.

An insufficient bond between copper layers can lead to electrical test failure.

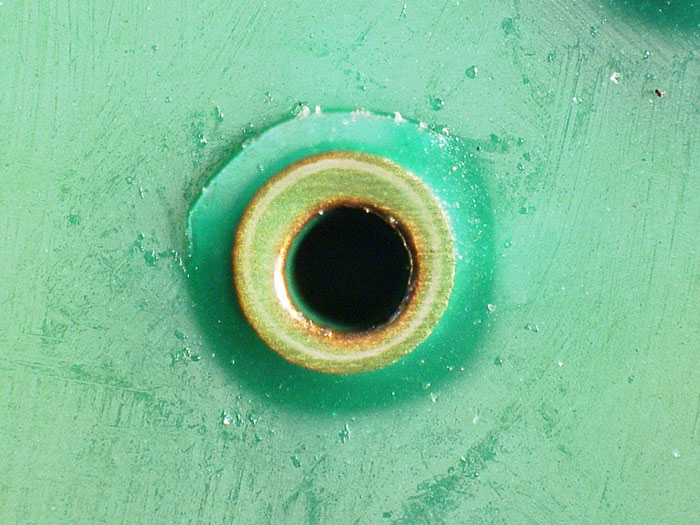

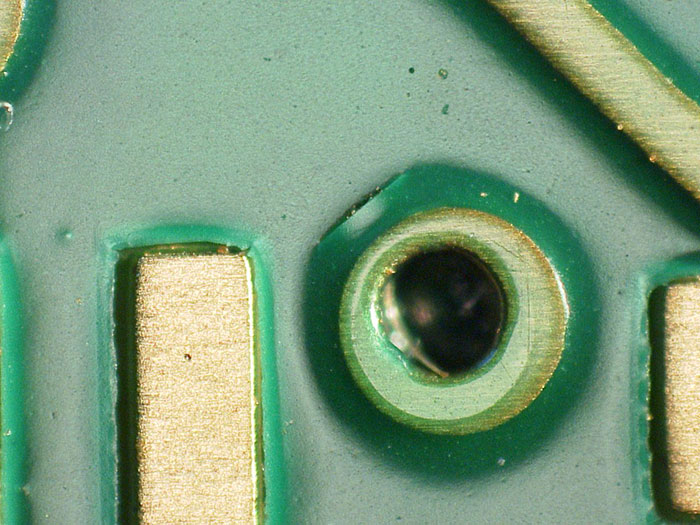

Delamination of printed circuit boards is typically associated with large blisters or bubbles in the board after soldering, but there are different examples of this phenomenon. The examples in FIGUREs 1a and b show via popping after reflow soldering, also known as “copper via rivet.”

In the images, the through via has elongated as the board expanded during heating. As layers in the multilayer board delaminated, further strain was placed on the copper plating until failure occurred. The board did fail electrical test, but the only problem visible on the surface of the board was the cracking of the solder mask, which can clearly be seen.

Cutting a section of the board around the via holes and separating the layers showed a lack of bonding in the multilayer. Examining the surface of the layers optically showed a lack of adhesion. Repeating the examination with microsections showed the copper separating due to the strain involved, but did prevent inspection of the innerlayer copper surfaces.

Figure 1. Examples of post-reflow via popping.

It can be argued moisture in the board can contribute to the expansion rate, but when there is a lack of bond between copper layers, the root cause is PCB manufacture.

These are typical defects shown in the National Physical Laboratory’s interactive assembly and soldering defects database. The database (http://defectsdatabase.npl.co.uk), available to all this publication’s readers, allows engineers to search and view countless defects and solutions, or to submit defects online. To complement the defect of the month, NPL features the Defect Video of the Month, presented online by Bob Willis. This describes over 20 different failure modes, many with video examples of the defect occurring in real time.

Martin Wickham is a consultant at the National Physical Laboratory (npl.co.uk); martin.wickham@npl.co.uk. His column appears monthly.