Solder Surface Deformation

When solder isn’t shaped correctly, the condition is known as head-in-pillow.

This month we show the ball surface on area array packages where no solder joint was formed. The joints were intermittent, but one of the surfaces – either the ball or the surface of the solder on the pad – was deformed. This is better known as head-in-pillow (HiP) or head-on-pillow (HoP), depending on the shape formed on the solder adjacent surface.

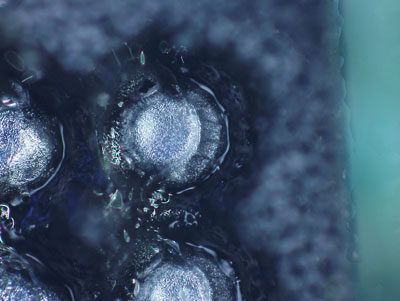

FIGURES 1 and 2 show examples of HiP/HoP. In Figure 1, the surface of the ball is shown after mechanically separating the device from the board. The indent of the solder from the pad on the board is visible.

Figure 1. The surface of the ball after mechanically separating the device from the board.

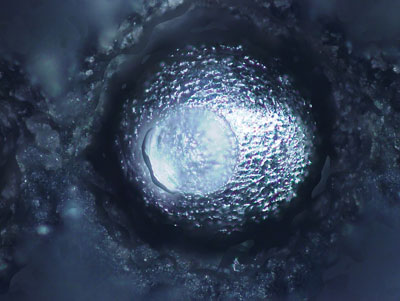

Figure 2, on the other hand, shows a ball with some residue but with no indentation. Compared with the corresponding PCB pad, it may show the reflowed solder being deformed.

Figure 2. A ball with some residue but with no indentation.

We have presented live process defect clinics at exhibitions all over the world. Many of our Defect of the Month videos are available online at youtube.com/user/mrbobwillis.

is a process engineering consultant; bob@bobwillis.co.uk. His column appears monthly.

Press Releases

- Federal Electronics Expands Nearshore Capacity with Additional PCBA Line in Hermosillo

- Mexican Electronics Manufacturer Improves PCB Reliability with I.C.T Conformal Coating Line

- Cape EMS Unveils ‘CEB 2.0’ Roadmap to Drive High-Value Tech and Infrastructure Growth

- ECIA Calls for Tariff Stability as New Global Trade Framework Takes Effect