Tester for Hire

Demand peaking and you can’t afford to buy? Consider renting.

The world of electronics manufacturing test goes through the tides of economic cycles, much like every other industry. Economic environment aside, electronics manufacturers juggle capacity according to seasonal demand for consumer products, site relocations, and to ensure a seamless test strategy right from product development at R&D stage, to mass manufacturing and product launch. Electronic manufacturing test equipment is a high-capital investment, so juggling test resources is as much art as economic science.

For those in the test equipment manager’s shoes, seasonal test equipment shortage can be quite a challenge. Let’s explore some solutions available as you fine-tune the art of balancing resources with the science of availing the best test solutions to your product lines to ensure ideal quality control.

For a start, you may consider shipping your end-product from different sites around the world to meet seasonal peak demand schedules. If there isn’t an available tester, then purchasing new ones would offer a quick fix, provided this was in the budget. Often though, the need for equipment and budget do not align.

If you lack the capital to purchase the test equipment needed, renting is a viable option. This helps conserve valuable capital, as by most accounting practices, rental payment is considered an operating expense.

From the business perspective, local rental equipment services open a new financing channel. With rates that can be fixed and payable on a monthly basis, a huge upfront capital outlay can be avoided, especially when facing a shortage of cash. The issue of capital equipment depreciation is avoided too.

A local rental agreement gives the flexibility of short-term commitment instead of sinking a huge investment into a single basket when peak demand tapers off and equipment is left idle. Usually, the rental qualification process is pretty simple, so that helps companies grasp business opportunities quickly, should they need to fulfill spikes in production orders. Working with local rental equipment providers can be a good approach in terms of face-to-face meetings to understand product specifications and requirements, ease of access to technical consultancy and faster after-sales support. Doing so also avoids the hassles of time zone, language, and culture differences that might come into play when an overseas supplier is engaged.

Benefits of renting. There are some obvious benefits of renting versus outright purchase of test equipment. Rental companies are responsible for ensuring the equipment they lease complies with safety checks before each delivery. The rental company is also responsible for ensuring the end-users’ application needs are fulfilled. These services should be at no extra cost to the end-user. In addition, rental companies are responsible for all tester software and hardware updates, thus removing the hassle of obsolescence management.

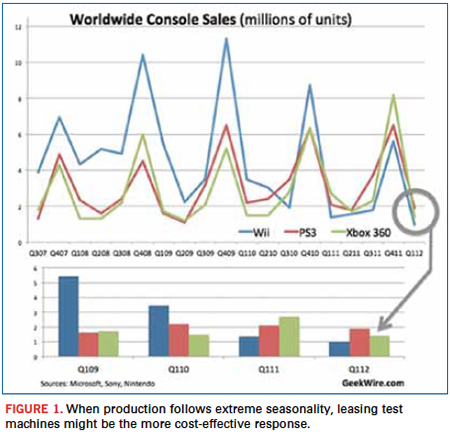

Let’s look at a real-life scenario. A China-based manufacturer faced the welcome challenge of seasonal orders spiking ahead of the year-end Christmas season. There was a high demand cycle during each approaching winter holiday season for popular gifts like xBox, PS4 and Wii. The manufacturer had to juggle the production lines with an almost overnight jump in demand for temporary test capacity for these various electronics games (Figure 1).

This particular manufacturer typically runs more than 20 production lines during peak season to meet demands. With each line needing three in-circuit testers, they would have needed 60 systems on site between August and January to support the ramped production. However, after this seasonal peak, the manufacturer typically does not need so many testers. After careful assessment of available test resources, the firm purchased only 25 additional in-circuit testers. For the peak season, they opted to rent 12 testers to boost test capacity.

The total rental cost for 12 systems worked out to around $864,000 for the six-month period. It would have required $4.2 million to buy 12 systems, with the added issue of managing idle capacity half of the year.

Third party or OEM? In the test equipment rental business market, the key players are third-party vendors and test equipment OEMs.

Third-party solution providers normally offer very cost-effective rental services, and these solutions may be sufficient to meet the “just-enough-test” criterion. Legal licensing should be reviewed; OEMs can issue licenses directly to the end-user, whereas it is not unusual for third-party vendors to infringe on licensing agreements in the process of activating software for their customers.

The equipment range should be compared as well. In general, OEMs will have all the latest hardware and software, whereas third-party vendors’ offerings may be more limited. Furthermore, OEMs often offer “rent to own” programs.

Seasonality and its inherent needs and challenges persist every year. Perhaps it’s time to think ahead of the next Christmas peak and put equipment rental in your budget.

Yang Hua is a product marketing engineer at Agilent Technologies (agilent.com); hua_yang@agilent.com.

Press Releases

- DATA MODUL expands EMS capabilities with fully integrated assembly and supply chain services

- ECIA Issues Industry Alert on Minnesota PFAS Regulation

- Libra Industries Appoints Mayur Mundra as Chief Financial Officer

- SMarTsol Strengthens Its Presence in the United States to Drive the High-Technology Industry