Circuit Technology Center Partners with Hentec RPS to Provide World-Class Component Modification Services

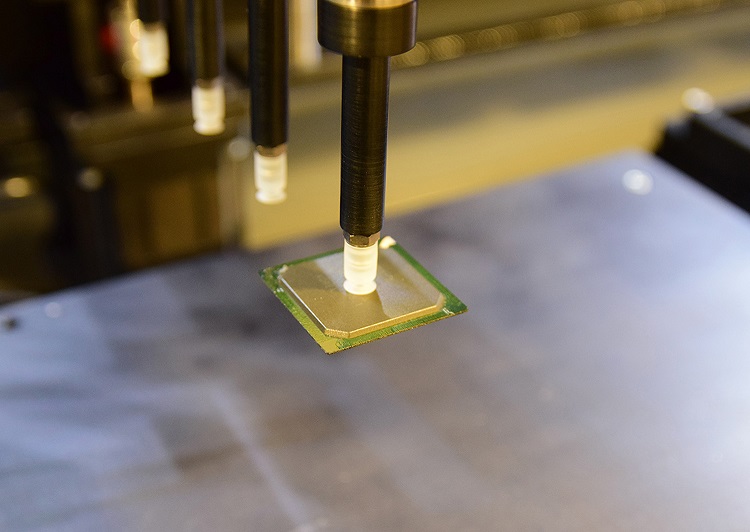

Available component modification services utilizing Hentec/RPS Odyssey RHSD systems include BGA de-balling, gold mitigation, lead tinning and tin whisker mitigation.

Newman Lake, WA (January 25, 2022) – Hentec Industries/RPS Automation is pleased to announce that the Circuit Technology Center has selected Hentec/RPS as their lead tinning equipment supply partner of choice. The Hentec/RPS Odyssey 1325 robotic hot solder dip machines are MIL spec complaint high-volume, high-mix lead tinning systems equipped with auto component load/unload that complies with all applicable GEIA-STD-006, MIL-PRF-38535, MIL-PRF-38524E and ANSI-J-STD-002 standards.

The Hentec/RPS state-of-the-art equipment allows Circuit Technology Center’s component level modification services department to meet the increasing demand from their defense and high reliability customer base that requires component level modification and alteration for tin whisker mitigation, gold mitigation, lead tinning re-conditioning applications and automated, touch-less BGA component de-balling.

About Circuit Technology Center

Founded in 1979, Circuit Technology Center continues to be recognized as the most innovative and reliable specialist in circuit board damage repair, rework, BGA re-balling and component level modification services in the world. For more information, please visit: www.circuitrework.com or phone 978-374-5000.

About Hentec Industries

Hentec Industries/RPS Automation is a manufacturer of automated selective soldering, component lead tinning, and solderability test equipment for electronics and electronic component manufacturing, assembly, and distribution. Hentec/RPS has been advancing automated soldering and lead finishing technology for defense, aerospace, automotive, contract manufacturers and micro-electronics component manufacturers since the early 90’s.

All Hentec/RPS products are designed and manufactured in Newman Lake, Washington. For more information, please visit www.rpsautomation.com.

Press Releases

- Benchmark Appoints Josh Hollin as Senior Vice President and Chief Technology Officer

- 2026 IEEE Electronic Components and Technology Conference Student Innovation Challenge Pre-registration Deadline Extended to January 11, 2026

- PCBsync PCB Assembly Introduces Full-Scale Electronic Manufacturing Service

- Magic Leap Partners with Pegatron for AR Glasses Components Production