Solder Wicking During Reflow

Are the chosen surface finishes optimal for the alloy?

Are the chosen surface finishes optimal for the alloy?

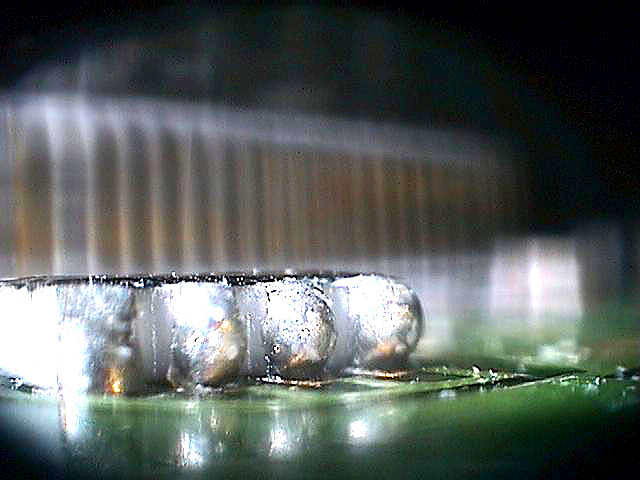

Solder wicking has occurred on the resistor network terminations. The solder, when reflowed, has wetted to the termination, instead of the pads on the NiAu board (FIGURE 1). This is due to contamination on the surface of the gold that the flux could not remove during reflow.

In this case it was due to cleaning the boards after poor printing, basically a paste wash-off in a poorly defined process. It is perfectly possible to wash a board after poor printing and reprint, but some surface coatings may not be compatible, or the process must be evaluated and controlled.

Figure 1. Solder wetting to terminations instead of pads.

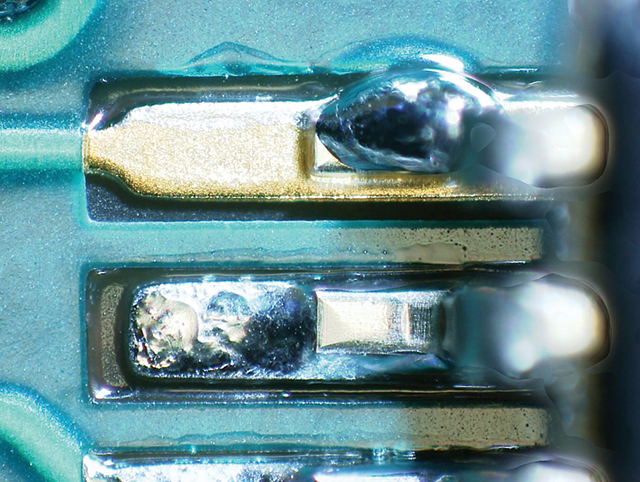

FIGURE 2 shows the same type of reflow wicking defect on a gullwing lead with the solder reflowing preferentially to the lead, rather than equally between the pad and lead.

Figure 2. Wicking defect on a gullwing leaded component.

These are typical defects shown in the National Physical Laboratory’s interactive assembly and soldering defects database. The database (http://defectsdatabase.npl.co.uk), available to all this publication’s readers, allows engineers to search and view countless defects and solutions, or to submit defects online. To complement the defect of the month, NPL features the Defect Video of the Month, presented online by Bob Willis. This describes over 20 different failure modes, many with video examples of the defect occurring in real time.

is a consultant at the National Physical Laboratory (npl.co.uk); martin.wickham@npl.co.uk. His column appears monthly.