Tin Whiskers on PCBs

Despite years of research, whiskering remains a problem.

Despite years of research, whiskering remains a problem.

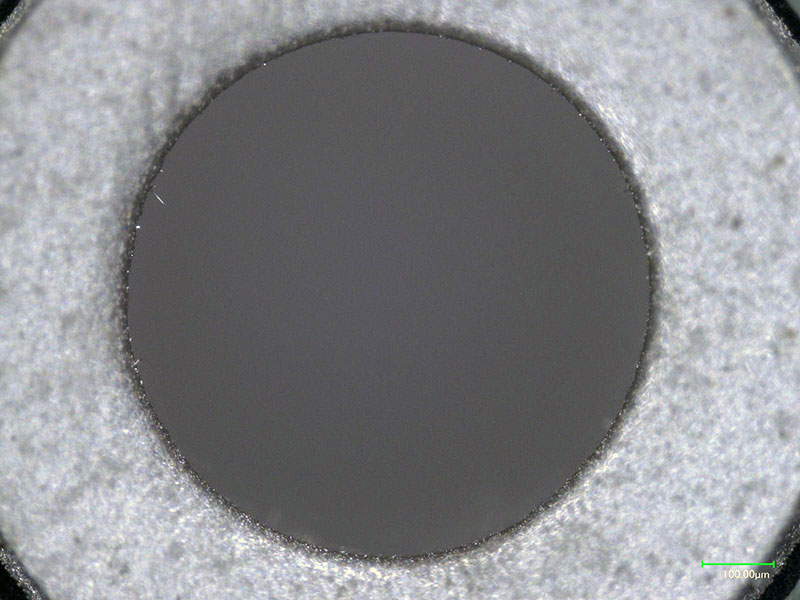

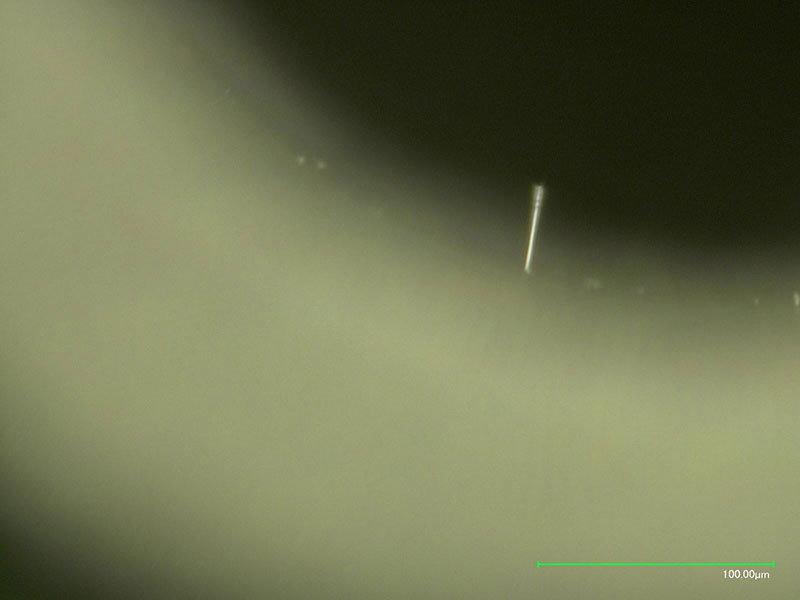

FIGURES 1a and 1b are examples of tin whisker growth on tin-finish printed circuit boards. You must have good eyesight to spot these. These examples were found on the surface of assembled boards. We have also seen much longer whiskers on boards supplied by producers just one week after manufacture. Other assessments have shown tin whiskers on the surface of a plated through-hole PCB coated with tin. The boards were produced and shipped to a manufacturing site in Europe and, when examined prior to assembly, were found to have whisker growth. Tin has become popular on printed boards as one of the alternative coatings, and has become the finish of choice in the component manufacturing industry. However, many concerns have been shared over the formation of whiskers and the long-term solderability of tin finish and its viability for double-sided soldering with long hold times between reflow or second stage soldering.

Figure 1. Tin whiskers on Sn-finish PCBs.

Considerable work and technical articles have been produced on whisker formation and the potential for failure in electronics. Much work is still being undertaken around the world on this subject. Yet, we still do not have guaranteed whisker-free products, or the process where the chemistry is used is not maintained correctly. Guidelines on designing a whisker-free process are followed, and materials that should not form tin whiskers selected, and yet somehow they still appear. This problem isn’t specifically a lead-free issue, as it has been around for years. Increased use of tin as a component finish and PCB metal finish has highlighted the potential for failure.

Organizations such as iNEMI and Jedec have guidelines on whisker formation causes, ways of accelerating testing for whisker formation, and preventative strategies. NPL has produced many reports on tin whisker formation and prevention methods, which can be downloaded free at defectsdatabase.npl.co.uk.

These are typical defects shown in the National Physical Laboratory’s interactive assembly and soldering defects database. The database (http://defectsdatabase.npl.co.uk), available to all this publication’s readers, allows engineers to search and view countless defects and solutions, or to submit defects online. To complement the defect of the month, NPL features the Defect Video of the Month, presented online by Bob Willis. This describes over 20 different failure modes, many with video examples of the defect occurring in real time.

is a consultant at the National Physical Laboratory (npl.co.uk); martin.wickham@npl.co.uk. His column appears monthly.

Press Releases

- Benchmark Appoints Josh Hollin as Senior Vice President and Chief Technology Officer

- 2026 IEEE Electronic Components and Technology Conference Student Innovation Challenge Pre-registration Deadline Extended to January 11, 2026

- PCBsync PCB Assembly Introduces Full-Scale Electronic Manufacturing Service

- Magic Leap Partners with Pegatron for AR Glasses Components Production