Solder Paste Slump

Try this test to determine paste problems.

Try this test to determine paste problems.

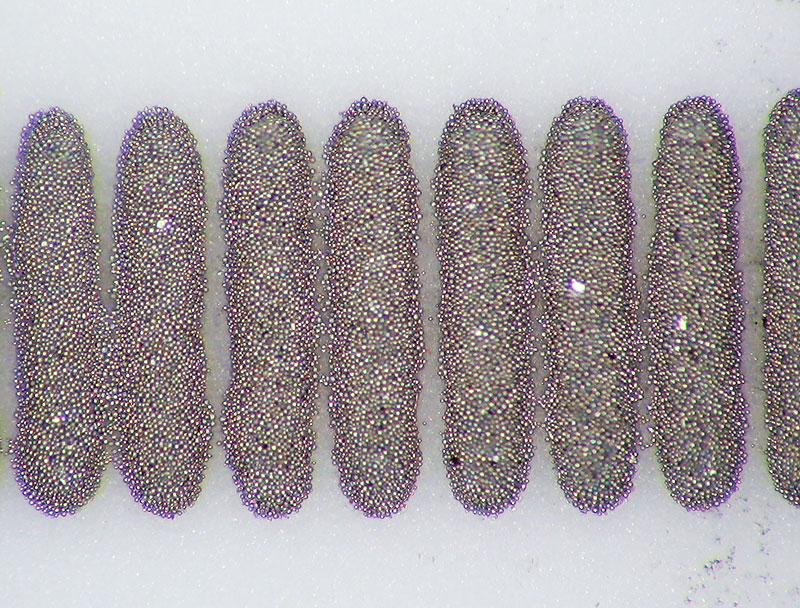

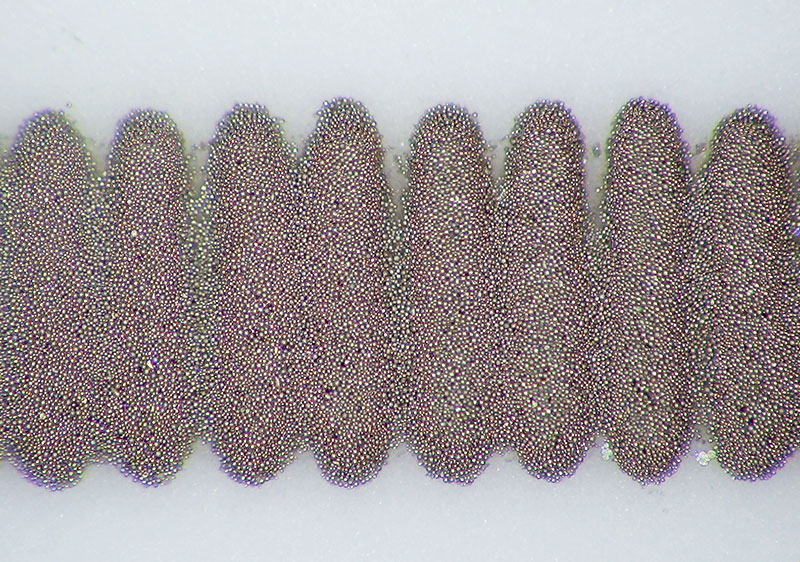

This month we look at solder paste slump during preheating. It is important to know how much, if any, of the paste slumps like butter on a hot day during reflow. If solder paste does slump, it can lead to shorts, solder balls or solder beads, or cause variations in solder joint volume on selected joints.

Variation in joint volume occurs when one joint acquires more solder from an adjacent joint during reflow due to the paste being linked. Testing of solder paste is well covered in IPC specifications, and equipment is available to test paste and record the results.

Alternatively, if you think you have an issue, a simple shop floor test is to use the existing profile but change the temperatures of the final reflow zones. Setting the final zones to final preheat temperatures will slow the degree of slump. Normally the maximum slump is seen earlier during reflow. Typically, as solder paste is changed or the metal particle size is reduced, slumping can be seen more often.

Figure 1. Different degrees of paste slump on white ceramic tiles as used in IPC test procedures.

We have presented live process defect clinics at exhibitions all over the world. Many of our Defect of the Month videos are available online at youtube.com/user/mrbobwillis.

is a process engineering consultant; bob@bobwillis.co.uk. His column appears monthly.