Voids in Conformal Coating

Solvents in holes can heat and "pop."

Solvents in holes can heat and "pop."

This month we look at voids or missing conformal coating. Depending on the lack of coating and position, this condition may result in acceptance or rejection. Normally with conformal coatings, small voids not specifically associated with electrical termination or bridging connections are acceptable, depending on the level of inspection criteria.

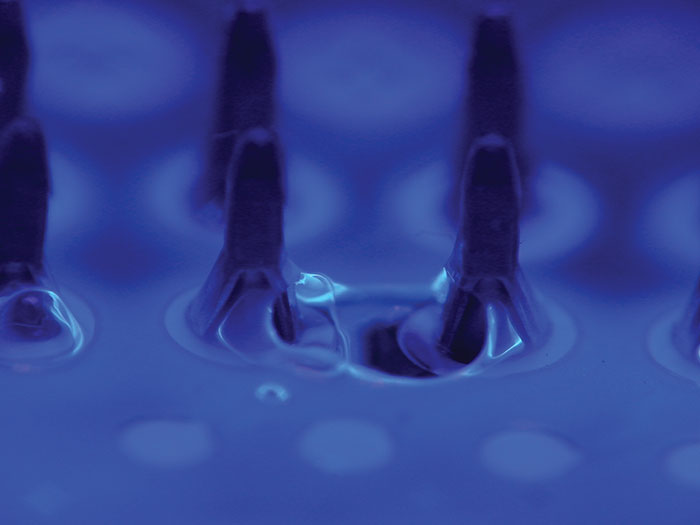

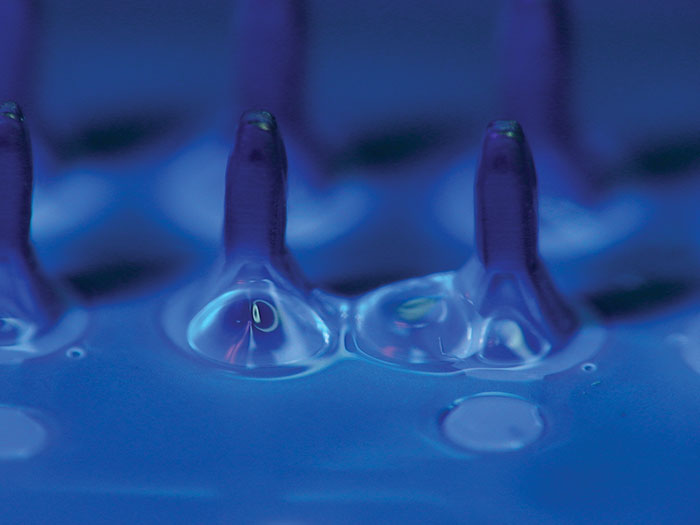

FIGURE 1 shows voids or bubbles in conformal coating under UV dark light. I would suggest both these cases require rework, as the electrical termination points are exposed, and there is no protection. Most likely, solvent coating has run into the holes. As the coating starts its first transition from a liquid, the voids expand from the holes. Then they pop, leaving the surface or pads with no protection.

It is suggested too much coating was applied on one pass, and initial evaporation could not occur, resulting in a volcano-like reaction from the holes. Each of the holes associated with coating voids had limited solder fill or cavities. In the past, we have seen the same problem with selective coating around press-fit connectors.

Figure 1. Conformal coating under UV dark light during inspection. Voids or bubbles are present around the termination, and voids also link two contacts.

We have presented live process defect clinics at exhibitions all over the world. Many of our Defect of the Month videos are available online at youtube.com/user/mrbobwillis.

is a process engineering consultant; bob@bobwillis.co.uk. His column appears monthly.

Press Releases

- Hon Hai Technology Group (Foxconn) Commits To New 5-Year Sustainability Roadmap Through 2030

- Amtech Electrocircuits Navigates Supreme Court Tariff Ruling

- Escatec Appoints Christa Schnider as Chief Sales Officer to Drive Global Growth

- PulseForge Makes Major Breakthrough Which Allows Flux-less Soldering in an Ambient Environment